Post chemical-mechanical polishing (CMP) cleaning method and CMP method

A chemical mechanical and post-cleaning technology, which is applied in the field of chemical mechanical grinding and cleaning, can solve the problems of easy sticking to the clean polysilicon surface, re-contamination, etc., achieve good cleaning effect and improve etching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

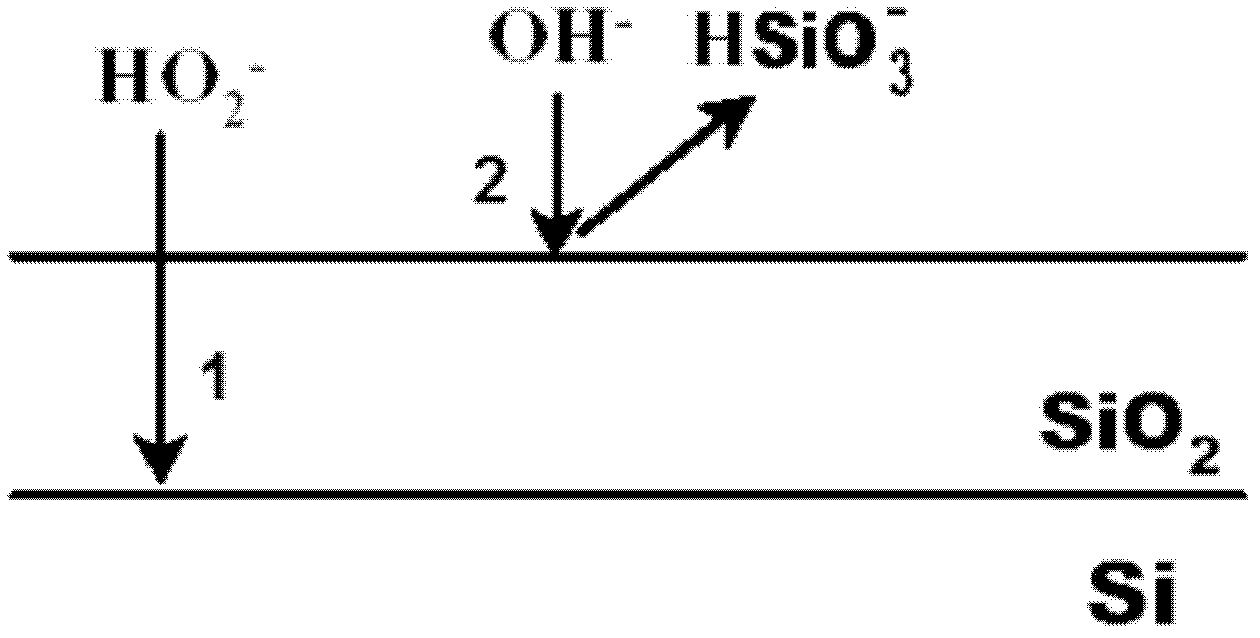

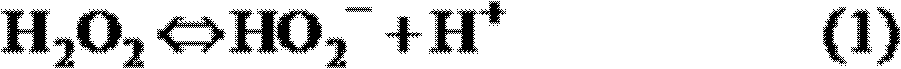

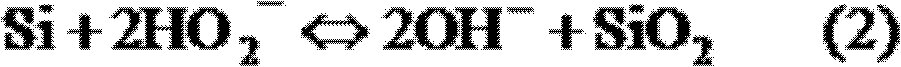

[0020] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0021] In prior art, NH in SCl solution 4 The mass percentage of OH is generally 2.0%+ / -0.2%, H 2 o 2 The mass percentage is generally 2.0%+ / -0.2%. Among them, the etchant in the SCl solution is NH 4 Oh.

[0022] Different from the above concentration of the prior art, the NH in the SCl solution 4 The mass percentage of OH is changed to 2.8+ / -0.2%; H 2 o 2 The mass percent was changed to 3.0+ / -0.2%.

[0023] That is, in the cleaning method after chemical mechanical polishing according to an embodiment of the present invention, first, in the megasonic cleaning step, using NH 4 The mass percentage of OH is 2.8+ / -0.2%, H 2 o 2 The SCl solution with a mass percentage of 3.0+ / -0.2% is used for megasonic cleaning; thereafter, in the PVA scru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com