Pumice wave absorbing aggregate with electromagnetic wave absorbing function and preparation method of pumice wave absorbing aggregate

An electromagnetic wave and pumice technology, applied in the fields of natural pumice absorbing aggregate and its preparation, light aggregate and its preparation, can solve the problems of low strength, high water absorption of pumice aggregate, uneven dispersion of wave absorbing agent, etc. The effect of low finished product price, good absorbing performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

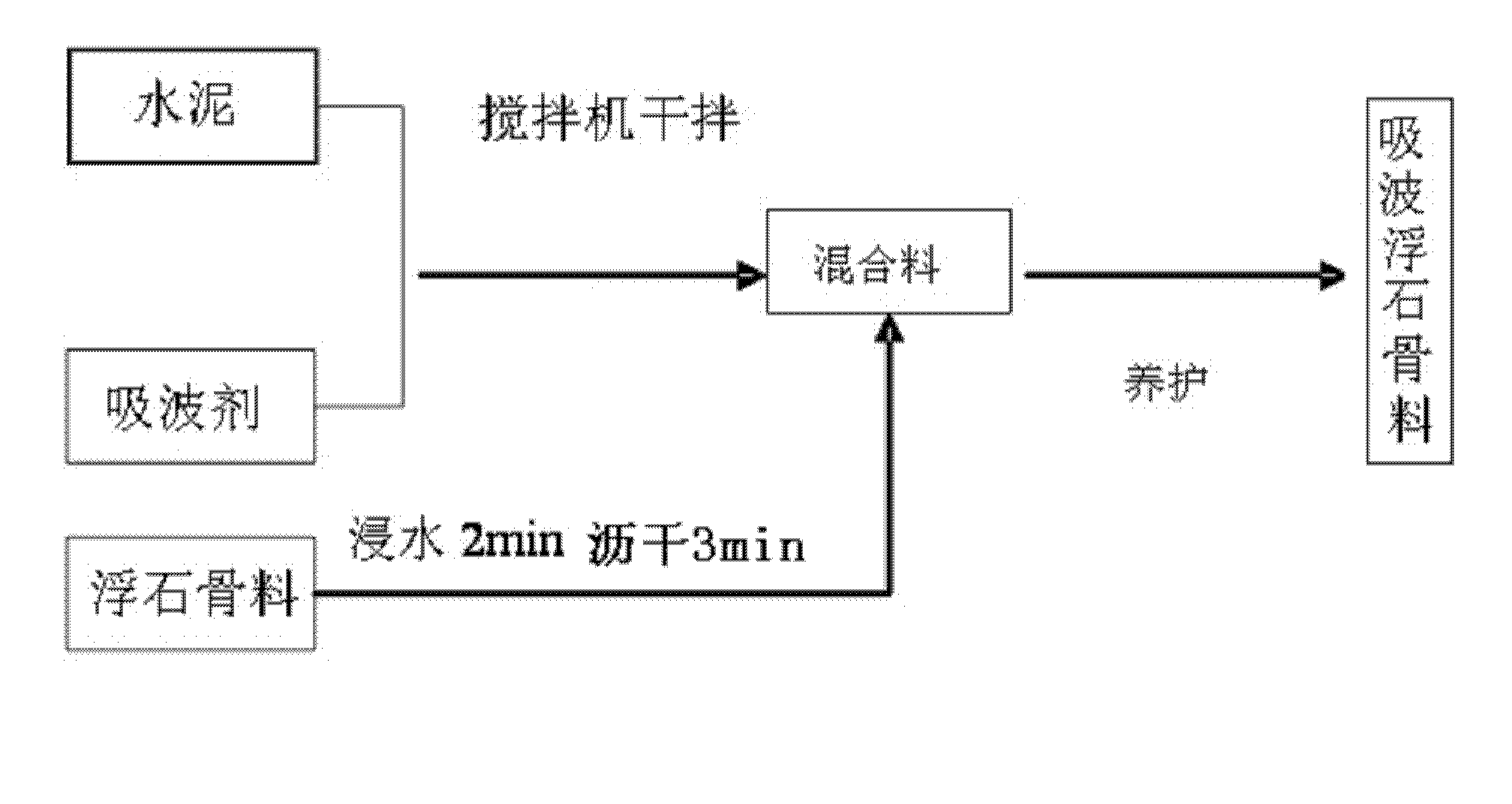

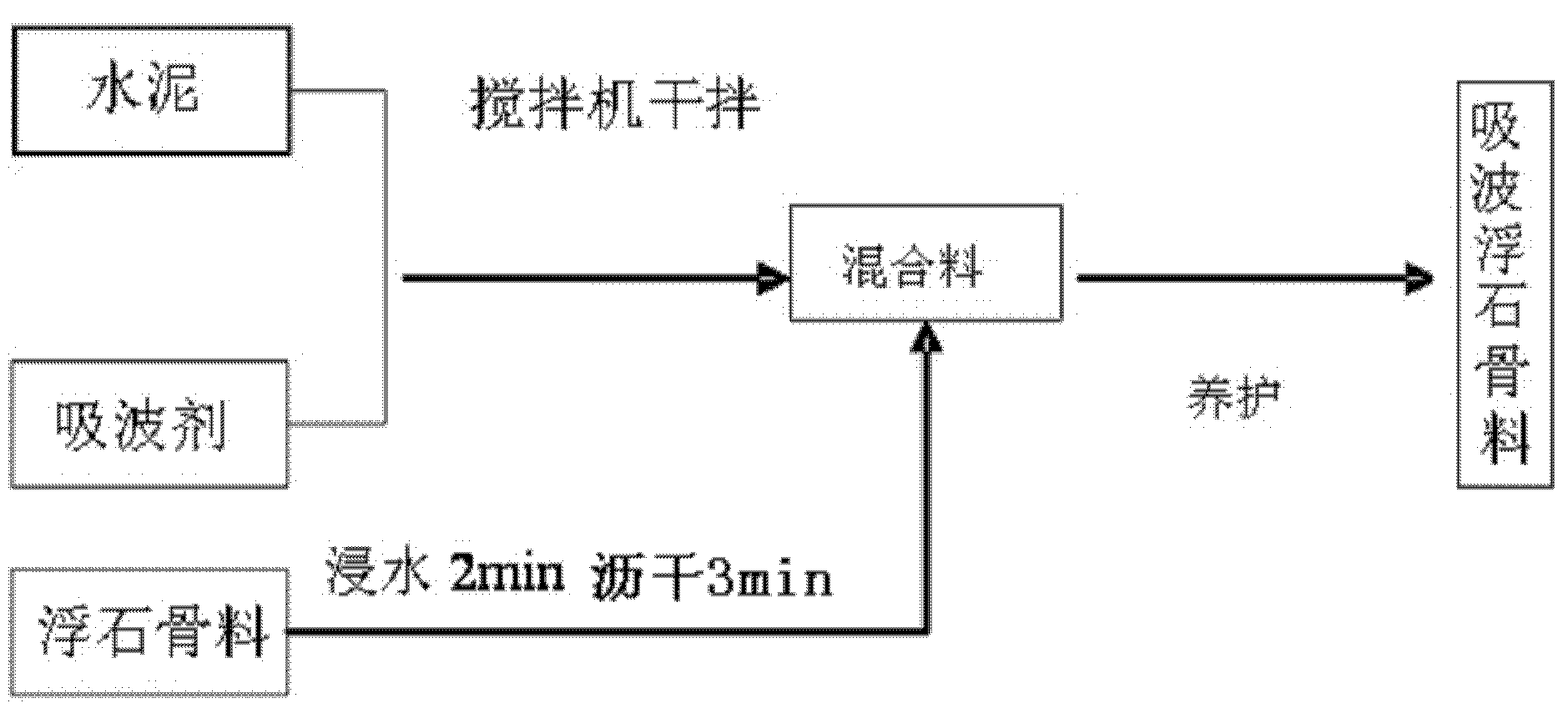

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, the weight ratio of cement and wave-absorbing agent is 90:10, and the wave-absorbing pumice aggregate is prepared according to the invention. According to GB / T17431.1-2010 "Light Aggregate and Its Test Method Light Aggregate Test Method", the bulk density, apparent density, cylinder compressive strength and water absorption of the aggregate are tested. The test results are as follows:

[0022] project

Bulk density, kg / m 3

Apparent density, kg / m 3

Cylinder compressive strength, MPa

Water absorption, %

Test Results

480

820

2.5

12.1

[0023] According to the weight ratio of cement, water, river sand, and wave-absorbing pumice aggregate of 1:0.50:1.6:1.0, light-weight aggregate wave-absorbing concrete was prepared, and a specimen with a size of 200mm*200mm*25mm was made. The absorbing concrete specimen was tested for absorbing performance, and the results are shown in the following tabl...

Embodiment 2

[0026] In this embodiment, the weight ratio of cement and wave-absorbing agent is 95:5, and the wave-absorbing pumice aggregate is prepared according to the invention. According to GB / T17431.1-2010 "Light Aggregate and Its Test Method Light Aggregate Test Method", the bulk density, apparent density, cylinder compressive strength and water absorption of the aggregate are tested. The test results are as follows:

[0027] project

Bulk density, kg / m 3

Apparent density, kg / m 3

Cylinder compressive strength, MPa

Water absorption, %

Test Results

490

830

2.2

13.8

[0028] The weight ratio of cement, water, expanded perlite, and wave-absorbing pumice aggregate is 1:0.50:0.10:1.5 to prepare lightweight aggregate wave-absorbing concrete, and make a specimen with a size of 200mm*200mm*25mm. The absorbing concrete specimen was tested for absorbing performance, and the results are shown in the following table:

[0029] ...

Embodiment 3

[0031] In this embodiment, the weight ratio of cement and wave-absorbing agent is 80:20, and the wave-absorbing pumice aggregate is prepared according to the invention. According to GB / T17431.1-2010 "Light Aggregate and Its Test Method Light Aggregate Test Method", the bulk density, apparent density, cylinder compressive strength and water absorption of the aggregate are tested. The test results are as follows:

[0032] project

Bulk density, kg / m 3

Apparent density, kg / m 3

Cylinder compressive strength, MPa

Water absorption, %

Test Results

490

820

2.3

11.6

[0033] According to the weight ratio of cement, water, river sand, and wave-absorbing pumice aggregate of 1:0.50:1.6:1.0, light-weight aggregate wave-absorbing concrete was prepared, and a specimen with a size of 200mm*200mm*25mm was made. The absorbing concrete specimen was tested for absorbing performance, and the results are shown in the following tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com