Method for producing all trans-teprenone

A technology of teprenone and all-trans, which is applied in the field of production of all-trans teprenone, can solve the problems that the separation degree cannot reach the expected goal, and it is difficult to produce in large quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

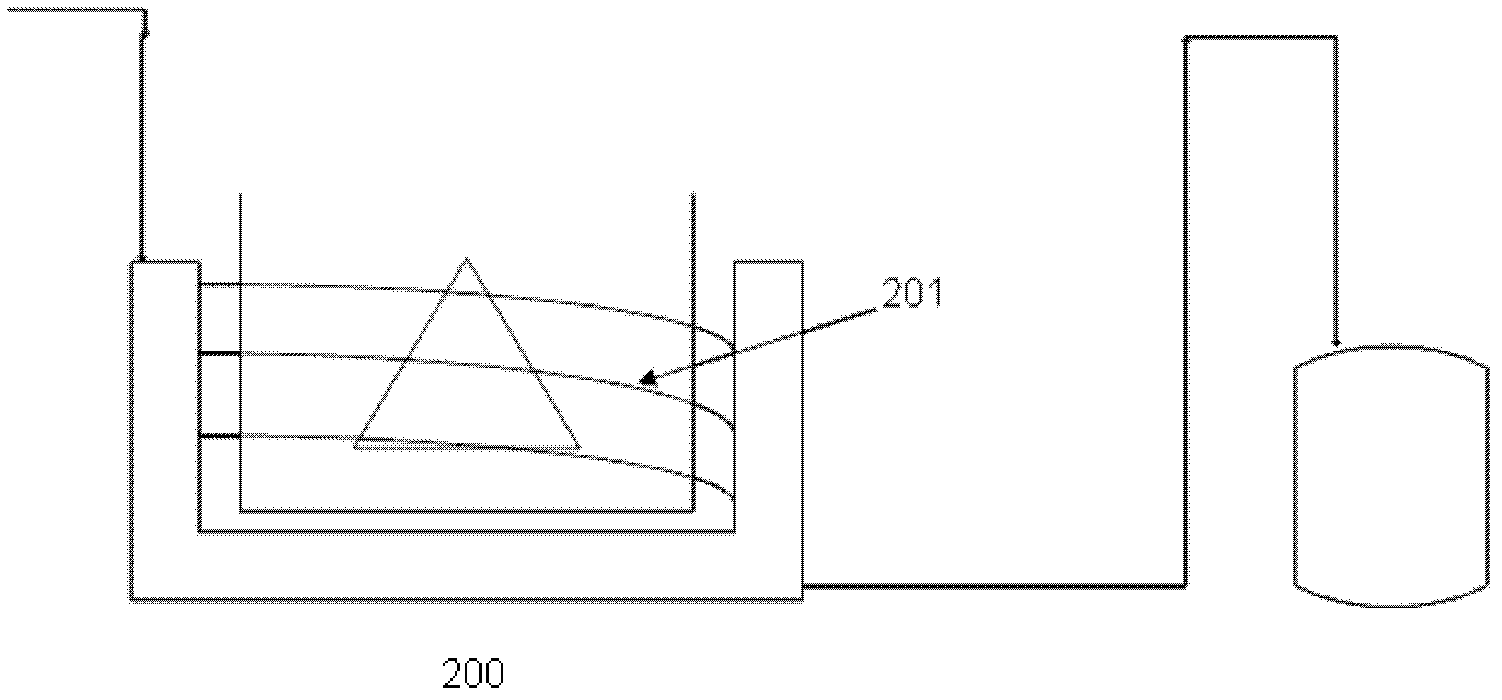

[0042] (1) After installing a glass column with a height of 400 mm and a diameter of 19 mm, a stirrer, and a thermometer on a 2500 ml glass four-necked flask, add 500 g of geranyllinalool, 280 g of methyl acetoacetate, and 8 g of aluminum isopropoxide. Raise the temperature, stir, slowly raise the temperature to 130°C and see bubbling, and methanol begins to flow out at 135°C, collect the methanol liquid, continue to heat up to about 170°C, stop heating, keep it warm for 4 hours, and after cooling down to room temperature, replace the above glass column Distillation under reduced pressure was carried out for a glass column with a height of 600 mm and a diameter of 24 mm. Use an electric heating mantle to start heating up, turn on the vacuum pump when the liquid phase temperature of the reaction liquid rises to 100°C, the vacuum degree is 0.9mmHg, and the temperature is about 140°C, the excess methyl acetoacetate gradually flows out from the reaction, and after all the methyl ac...

Embodiment 2

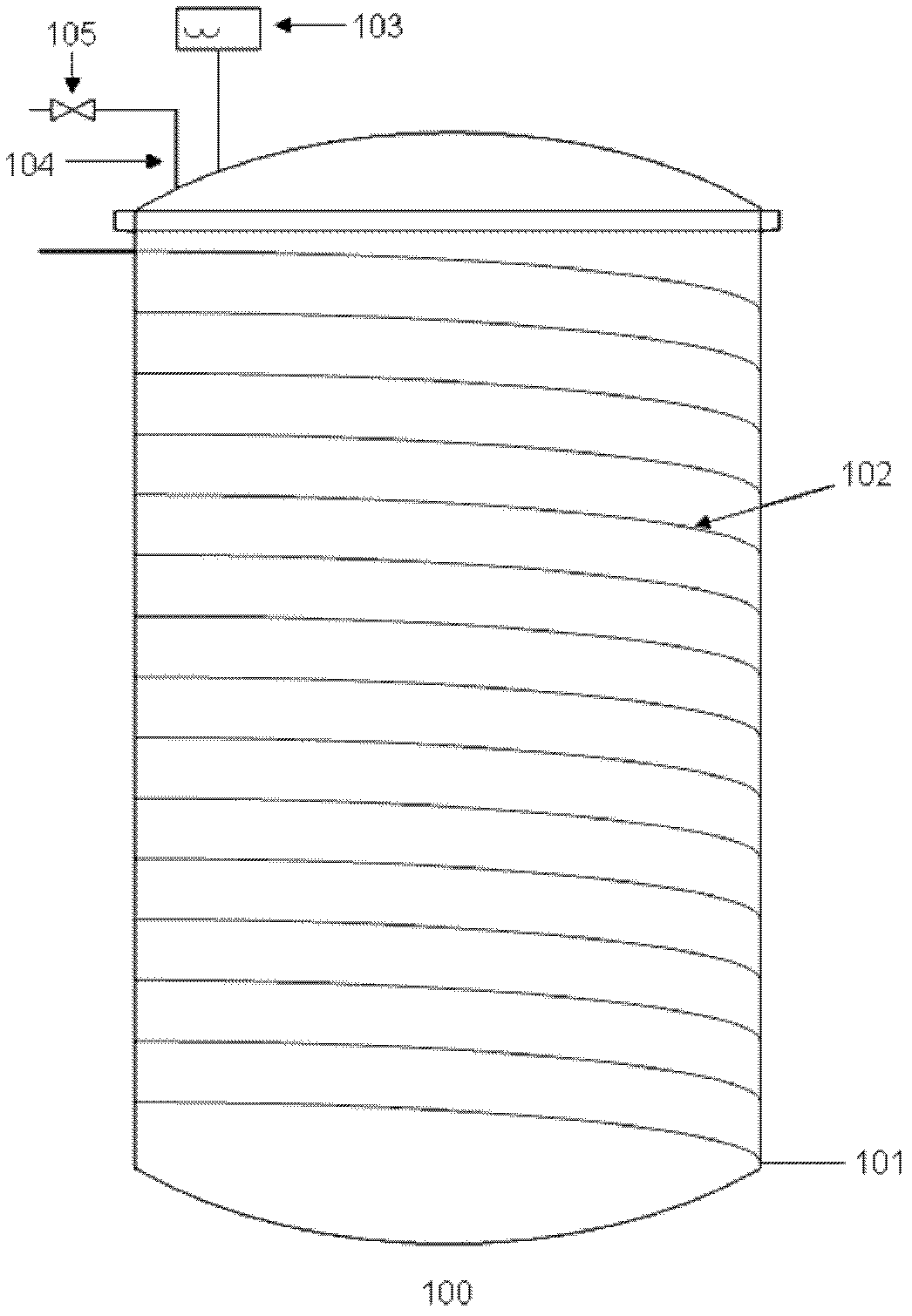

[0049] (1) Put 6.4Kg of geranyllinalool, 3.6Kg of methyl acetoacetate, and 102g of aluminum isopropoxide into a 20-liter stainless steel reaction tank. After stirring evenly, the temperature began to rise. Under stirring, the temperature was slowly raised to 135°C and methanol began to flow out, and the methanol liquid was collected. Continue to heat up to about 170°C, stop heating, start to keep warm for 4 hours, and then drop to normal temperature. Install a vacuum distillation device, the vacuum degree is 0.8mmHg, and start to heat up. At about 140°C, as the reaction deepens, excess methyl acetoacetate gradually flows out. After all the methyl acetoacetate is evaporated, the temperature is raised to 180°C. The crude renone (mixed type) began to flow out, and it was all evaporated at 190°C, and the residue in the kettle was centrally disposed of.

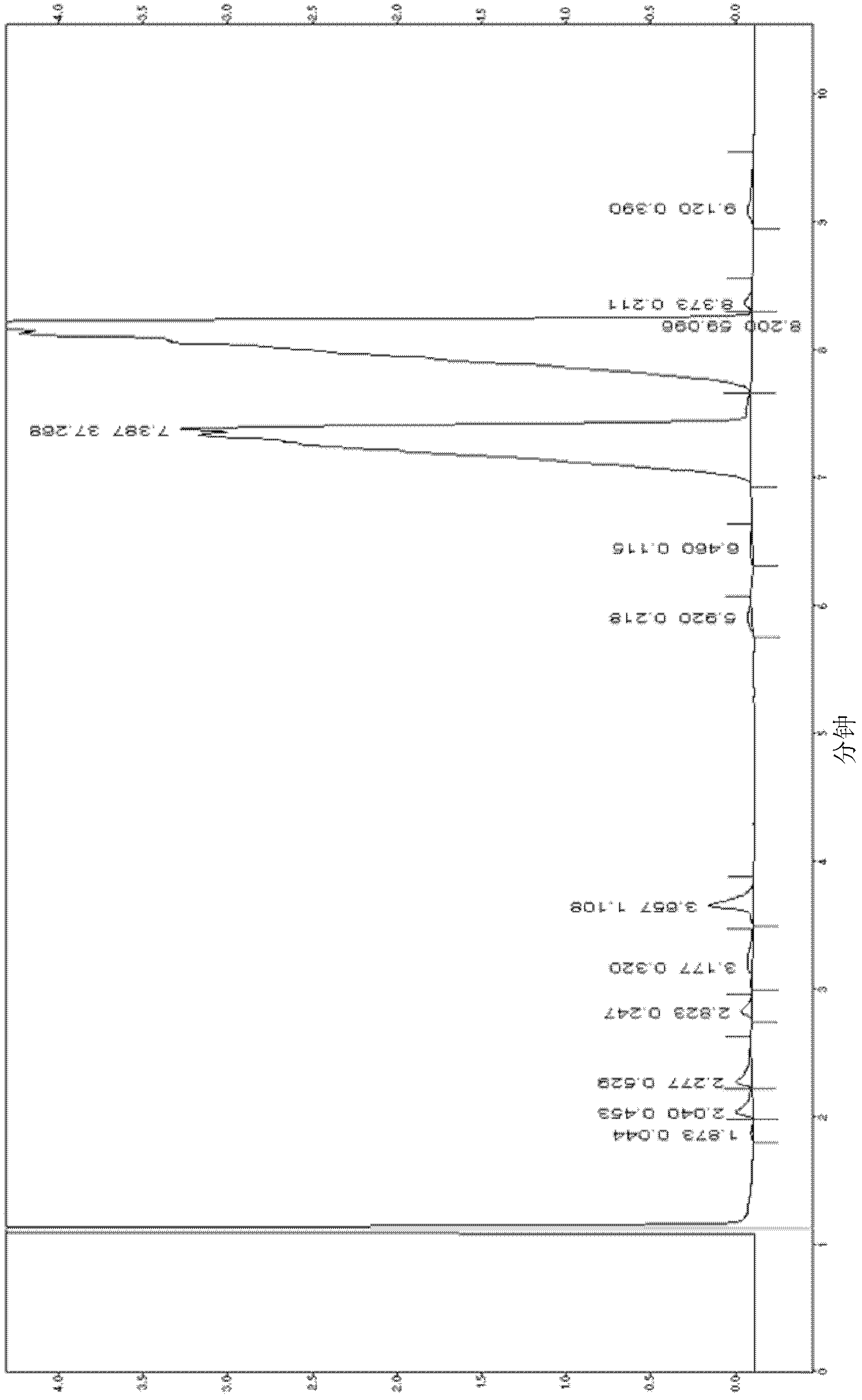

[0050] Take out and weigh to get the crude product teprenone 6.33Kg, take a sample, measure with Shimadzu GC-14C gas chromatogr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com