Method for preparing high-purity isobutene from raffinate C4 by means of separation

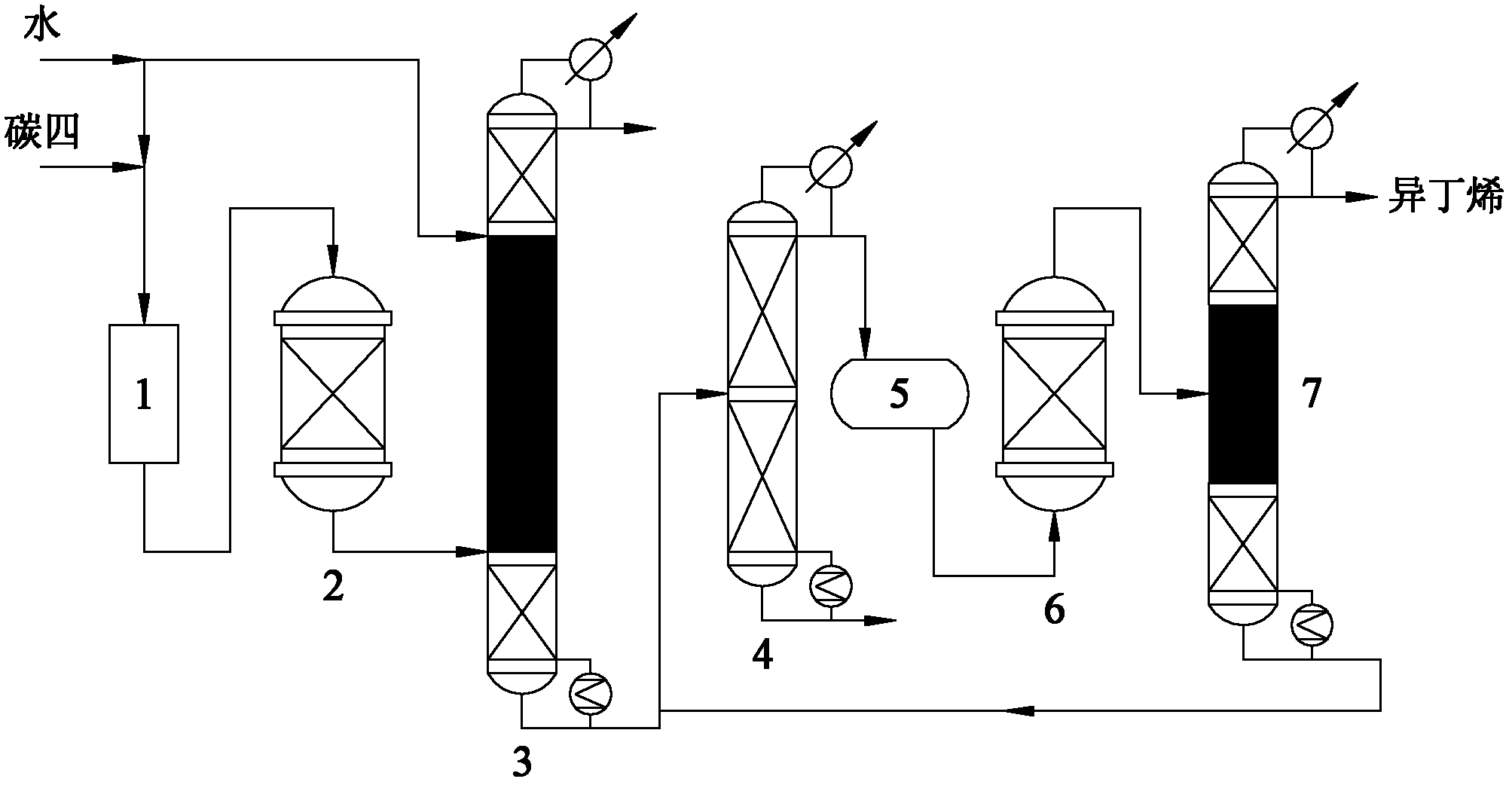

An isobutene, high-purity technology, applied in the direction of chemical change purification/separation, sustainable manufacturing/processing, organic chemistry, etc., can solve the problems of limited conversion rate, low equipment investment, and low single-pass conversion rate of tert-butanol dehydration reaction , to achieve the effect of improving conversion rate and selectivity, simplifying process flow, and facilitating separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

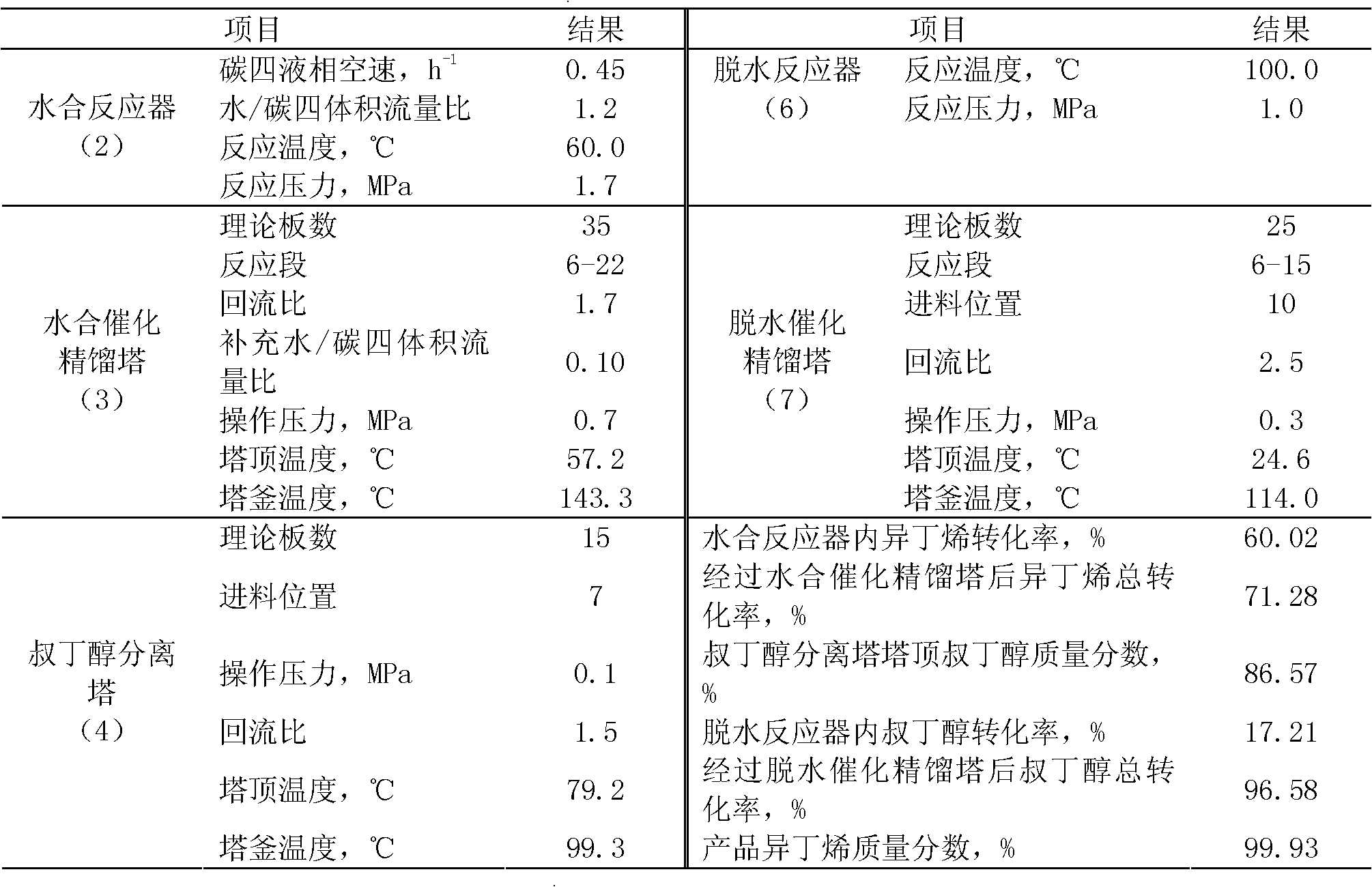

Embodiment 1

[0033] High-purity isobutene is prepared by separating and preparing high-purity isobutene from the by-product C4 fraction of the refinery fluidized catalytic cracking (FCC) unit after extracting butadiene, and the mass percentage content of isobutene in the raffinate C4 is 25.52%. The operating conditions and results are shown in Table 1, and the mass fraction of the product isobutene reaches 99.93%.

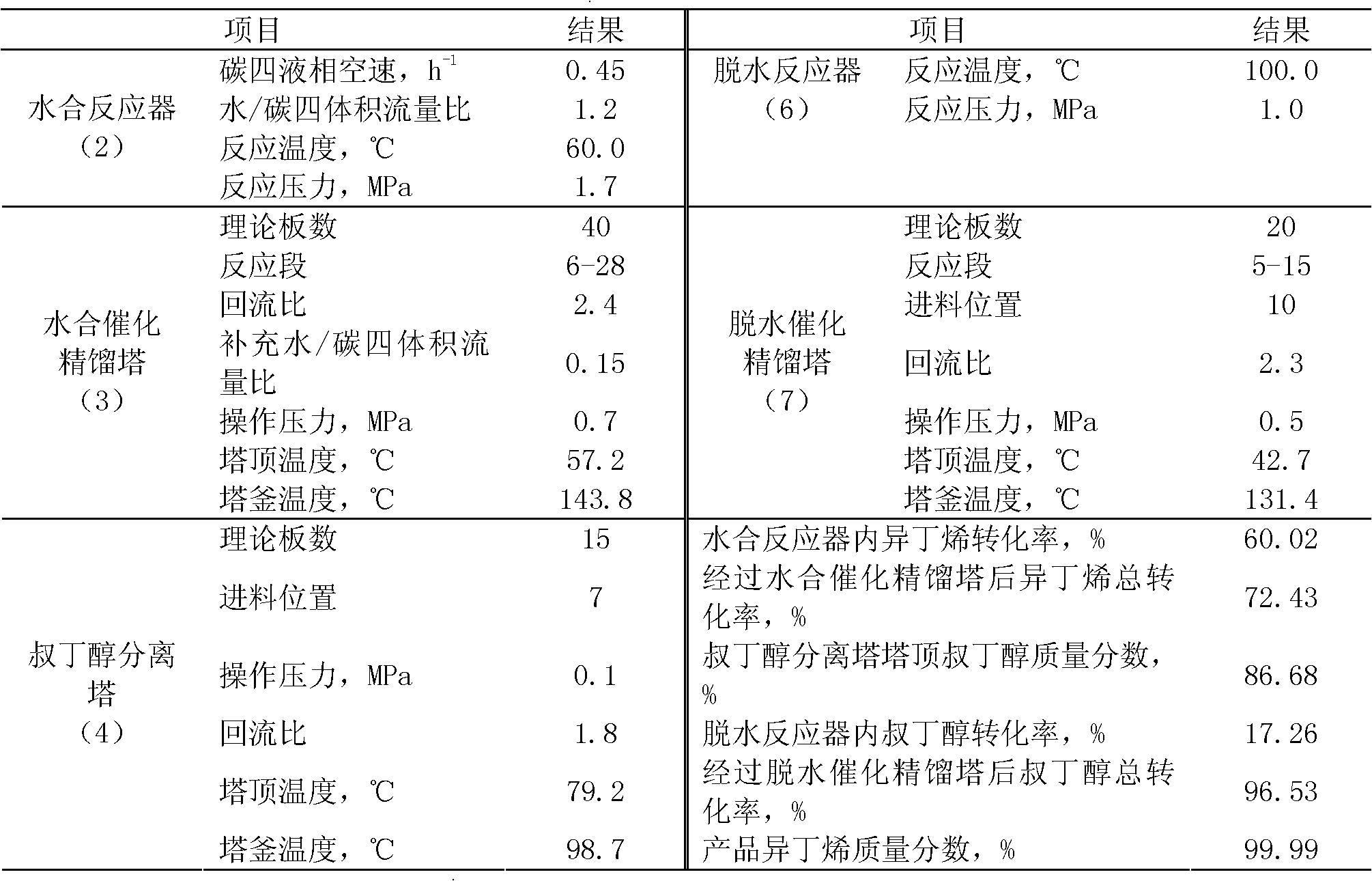

Embodiment 2

[0035] High-purity isobutene is prepared by separating and preparing high-purity isobutene from the by-product C4 fraction of the refinery fluidized catalytic cracking (FCC) unit after extracting butadiene, and the mass percentage content of isobutene in the raffinate C4 is 25.52%. The operating conditions and results are shown in Table 2, and the mass fraction of the product isobutene reaches 99.99%.

Embodiment 3

[0037] High-purity isobutene is separated and prepared by using the by-product C4 fraction of the steam cracking ethylene plant after extracting butadiene as raw material, and the mass percent content of isobutene in the raffinate C4 is 46.67%. The operating conditions and results are shown in Table 3, and the mass fraction of the product isobutene reaches 99.92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com