Continuous crystallizing method for acephate

A technique for crystallization of acephate, which is applied in the field of continuous crystallization of acephate solution to produce high-content crystallization of acephate, can solve the problems of small capacity of a single set of equipment, easy to generate wall formation, and high energy consumption, and achieve Reduce energy consumption and solve the effect of finer grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

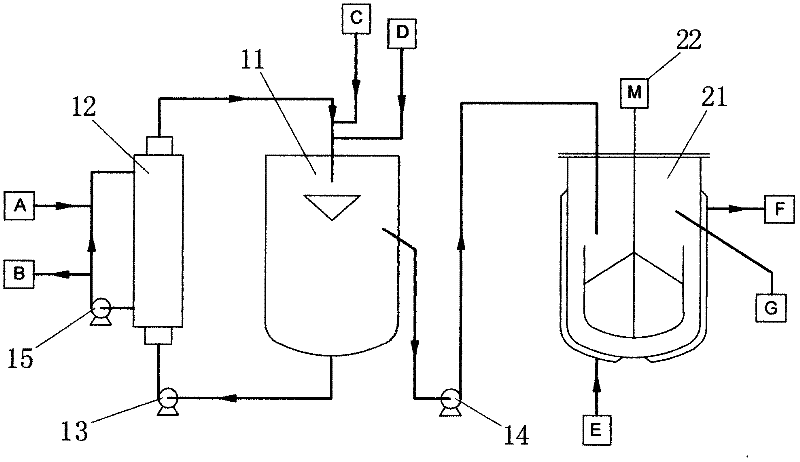

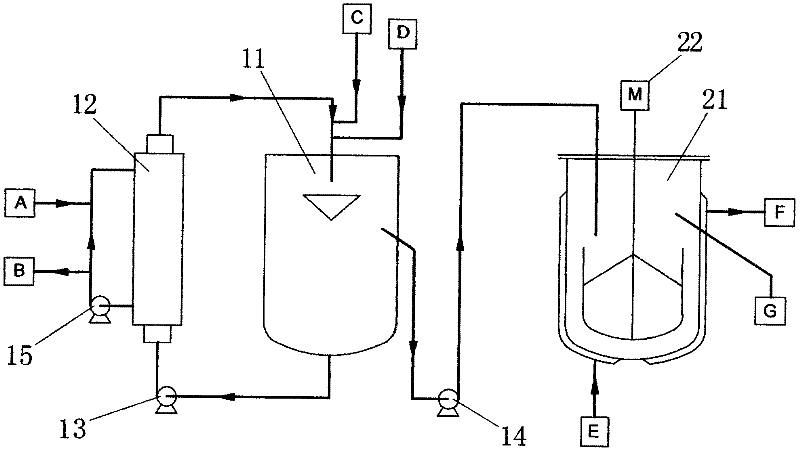

[0018] Equipment Specifications:

[0019] Pre-crystallizer buffer storage tank volume: 20m 3 ;

[0020] Heat exchanger, tubular type, heat exchange area: 300m 2 :

[0021] Volume of the second crystallizer: 30m 3 ;

[0022] Second-stage crystallizer jacket heat exchange area: 35m 2 .

[0023] The acephate solution produced with thiophosphoramide as raw material is desolvated by a thin film evaporator, the acephate content is 45%, the temperature is 58°C, and the flow rate is 4m 3 / h, enter the distribution hopper of the buffer storage tank 11 of the pre-crystallizer from port D through the potential difference, and enter the heat exchanger 12 through the circulation pump 13 for heat exchange. The distribution bucket on the top of the pre-crystallizer buffer storage tank 11, the temperature in the pre-crystallizer buffer storage tank 11 is controlled at 35°C. According to the liquid level setting, the material is transported to the middle of the secondary crystallizer 2...

Embodiment 2

[0025] The equipment used is the same as in Example 1.

[0026] The acephate solution produced with thiophosphoramide as raw material is desolvated by a thin film evaporator, the acephate content is 53%, the temperature is 65°C, and the flow rate is 3.4m 3 / h, enter the distribution hopper of pre-crystallizer 11 from port D by potential difference, and mother liquor (acephate content 18%) passes flow control 1m from continuous separation device 3 / h replenishes into the pre-crystallizer 11 through port C, controls the concentration of acephate in the pre-crystallizer 11 to be 45%, enters the heat exchanger 12 through the circulation pump 13 for heat exchange, and the heat exchanger controls the wall temperature difference 3 ℃, and the material It enters the distribution hopper at the top of the pre-crystallizer 11 through the circulation guide pipe, and the temperature in the pre-crystallizer 11 is controlled at 37°C. According to the liquid level setting, it is transported t...

Embodiment 3

[0028] The equipment used is the same as in Example 1.

[0029] The acephate solution produced with thiophosphoramide as raw material is desolvated by a thin-film evaporator, the acephate content is 56%, the temperature is 78°C, and the flow rate is 3.2m 3 / h, enter the distribution hopper of the pre-crystallizer 11 from port D through the potential difference, and the mother liquor (acephate content 18%) passes through the flow control 1.3m from the continuous separation device 3 / h replenishes into the pre-crystallizer 11 through port C, controls the concentration of acephate in the pre-crystallizer 11 to be 45%, enters the heat exchanger 12 through the circulation pump 13 for heat exchange, and the heat exchanger controls the wall temperature difference 5 ℃, and the material Enter the distribution hopper at the top of the pre-crystallizer 11 through the circulation guide pipe, the temperature in the pre-crystallizer 11 is controlled at 40°C, and according to the liquid leve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap