Preparation method of aqueous emulsion type polyvinyl chloride resin non-toxic terminator

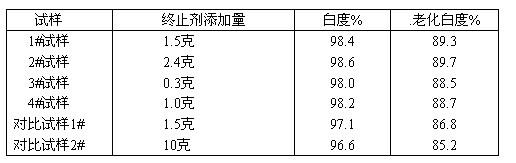

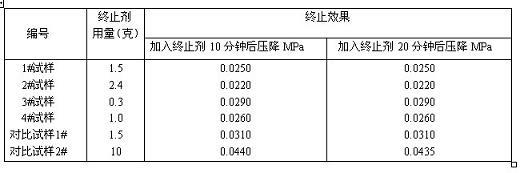

A technology of polyvinyl chloride and terminator, which is applied in the field of preparation of water-emulsion type polyvinyl chloride resin non-toxic terminator, which can solve the problem of insignificant anti-thermal and oxygen aging effect of resin, relatively toxic ATSC substances, large ATSC substances, etc. problems, achieve good synergistic effect, inhibit thermal degradation reaction and early coloring of aging, high whiteness and aging whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Mix 250g of styrenated o-tert-butylphenol product, 2.5g of N,N-bis(octadecyl)hydroxylamine, 16g of diethylhydroxylamine, and 12.5g of tin mercaptide into a 1000mL beaker and heat to 60 ℃, stir and melt evenly to make a compound liquid terminator; when the temperature drops to 40℃, add 15g of nonylphenol polyoxyethylene ether, use SHW400R high-shear mixing emulsifier, stirring speed 3500~4000 rpm, homogeneous Pre-emulsify and stir for 10 minutes, mix and dissolve 60g of 25% potassium abietate and 200g of deionized water, and slowly add it to the compound liquid terminator under high shear. emulsified for 30-40 minutes; after emulsification, slowly reduce the shear speed, and lower the temperature to 20-25°C at a low shear speed to obtain 2# water emulsion type polyvinyl chloride resin non-toxic terminator product (2# terminator ).

Embodiment 2

[0046] Mix 250g of styrenated o-tert-butylphenol product, 4g of dibenzylhydroxylamine, 10g of diethylhydroxylamine, and 20g of tin mercaptide into a 1000mL beaker, heat to 80°C, stir and melt evenly, and make a compound type Liquid terminator; when the temperature drops to 40°C, add 17g nonylphenol polyoxyethylene ether, use a SHW400R high-shear mixing emulsifier, stir at a speed of 3500~4000 rpm, homogeneously pre-emulsify and stir for 10 minutes, and mix 80g 25% Potassium rosinate and 210g deionized water are mixed and dissolved, and slowly added to the compound liquid terminator under high shear. Reduce the shear rate and lower the temperature to 20-25°C at a low shear rate to obtain 1# water emulsion type polyvinyl chloride resin non-toxic terminator product (1# terminator).

Embodiment 3

[0048] 250g of styrenated o-tert-butylphenol product, 12.5g of N,N-bis(hydrogenated tallow) amine prepared by direct oxidation of N,N-dialkylhydroxylamine product, 20g of diethylhydroxylamine, 37g of methyl mercaptan Add the tin into a 1000mL beaker after mixing, heat to 90°C, stir and melt evenly, and make a compound liquid terminator; when the temperature drops to 40°C, add 24g of isotridecanyl polyoxyethylene ether, and use a SHW400R high-shear mixing emulsifier , the stirring speed is 3500~4000 rpm, homogeneous pre-emulsification and stirring for 10 minutes, 120g 25% potassium abietate and 200g deionized water are mixed and dissolved, and slowly added to the composite liquid terminator under high shear, adding After completion, homogeneously emulsify at 3500~4000 rpm for 30~40 minutes; after emulsification, slowly reduce the shear speed, and lower the temperature to 20-25°C at a low shear speed to obtain 3# water emulsion type polyvinyl chloride Resin non-toxic terminator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com