Preparation method of low-residual-monomer N-vinyl butyl lactam homopolymer K90 aqueous solution

A vinylbutyrolactam and homopolymer technology, which is applied in the field of preparation of low-residue mono-N-vinylbutyrolactam homopolymer K90 aqueous solution, can solve the problem of high residual raw materials, and achieves simple preparation, ingenious design and suitable The effect of large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

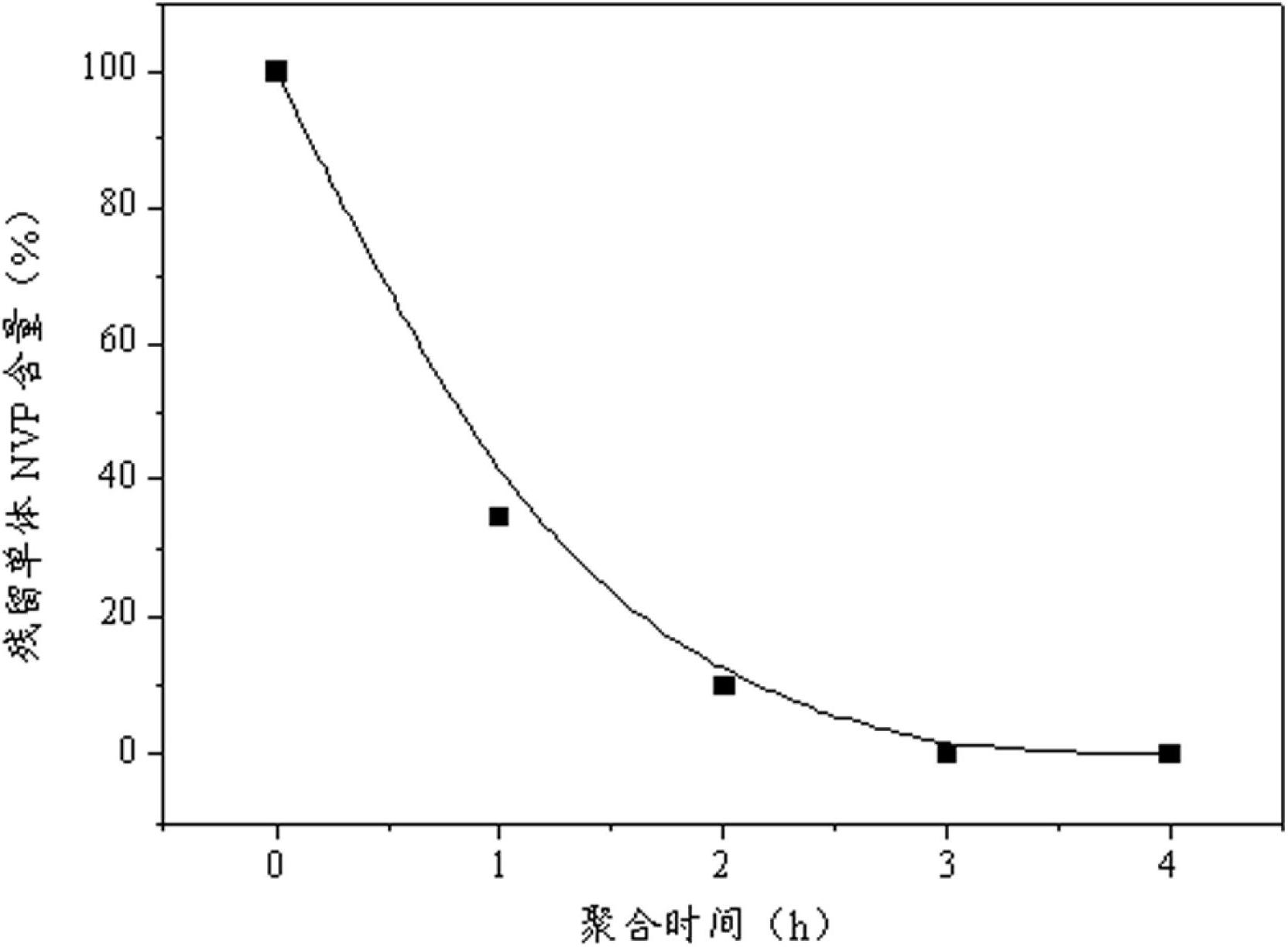

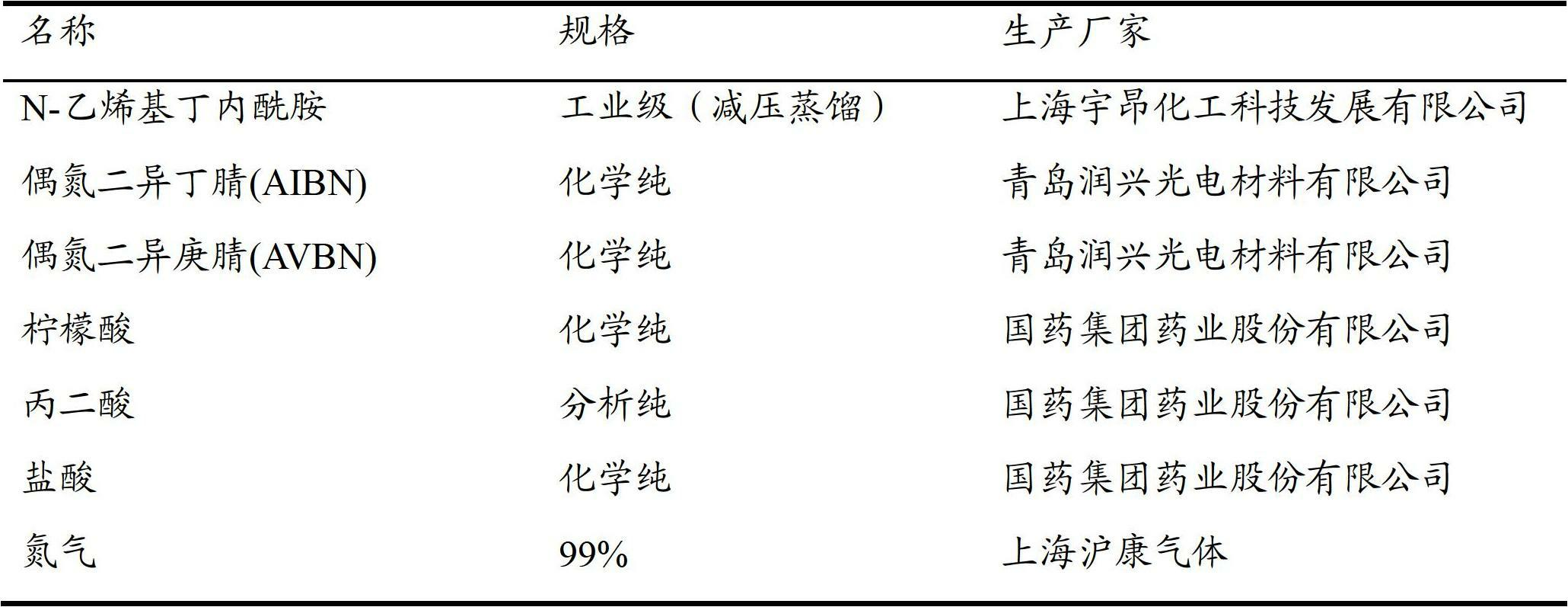

[0078] In this experiment, the reaction concentration is 18% by weight of N-vinylbutyrolactam monomer aqueous solution, and the total weight of initiator added is: 0.32% (relative to the mass ratio of monomer N-vinylbutyrolactam). Add 287 parts of water as a reaction solvent to a reaction vessel equipped with a gas inlet, a condenser, and a thermometer, introduce nitrogen while stirring, and exhaust the air in the reaction vessel to form a nitrogen atmosphere. Next, after heating with an oil bath so that the internal temperature of the reaction vessel reached 70°C, 63 parts of N-vinylbutyrolactam and 0.08 parts of initiator produced by Shanghai Yuang Chemical Technology Development Co., Ltd. were added. Azobisisobutyronitrile / azobisisoheptanonitrile=5 / 5 composition. After 1h, add 0.06 part of initiator again, continue to react after 0.5h, continue to add 0.04 part of initiator, after 0.5h, add 0.02 part of initiator, after continuing to react for 1.5h, add malonic acid / Mix h...

Embodiment 2

[0084] The difference from Example 1 is that the total weight of the initiator added is: 0.01% (relative to the mass ratio of monomer NVP); an oil bath is used to heat the internal temperature of the reaction vessel to 90°C; the initiator is composed of azobisisobutyl Nitrile / Azobisisoheptanonitrile=7 / 3 composition; add 0.003 parts of initiator for the first time, after 1h, add 0.0012 parts of initiator, continue to react for 0.5h, continue to add 0.0006 parts of initiator, 0.5h Finally, add 0.0012 parts of initiator, and continue the polymerization reaction for 0.5h after adding the initiator; the mixed acid for the first time is a mixed acid in equal proportions of malonic acid / hydrochloric acid, and the pH is adjusted to be 7, and the mixed acid for the second time is sulfuric acid / hydrochloric acid =8 / 2 mixed acid, adjust the pH to 5, and the interval between two acid additions is 1h. Prepare the N-vinylbutyrolactam concentration in the reaction liquid of PVPK90 polymer to...

Embodiment 3

[0086] The difference from Example 1 is that the total weight of the added initiator is: 3% (relative to the mass ratio of monomer NVP); an oil bath is used to heat the internal temperature of the reaction vessel to 55°C; the initiator is composed of azobisisobutyl Nitrile / Azobisisoheptanonitrile=3 / 7 composition; add 1.134 parts of initiator for the first time, 1h later, add 0.378 parts of initiator, continue to react for 0.5h, continue to add 0.189 parts of initiator, 0.5h Finally, add 0.378 parts of initiator, and continue the polymerization reaction for 2 hours after adding the initiator; the mixed acid for the first time is a mixed acid of sulfuric acid / hydrochloric acid=3 / 7, adjust the pH to 5, and the mixed acid for the second time is malonic acid / sulfuric acid = 1 / 9 mixed acid, adjust the pH to 2, and the interval between two acid additions is 5h. An aqueous solution with a PVPK90 concentration of 18% was prepared, the residual N-vinylbutyrolactam concentration was 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com