Composite electromagnetic shielding material for cables

A technology of composite electromagnetic and shielding materials, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of limited filling amount, the volume fraction cannot be too large, and the dielectric constant is small, so as to achieve improved electromagnetic shielding performance and good application prospects. , the effect of density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0020] Surface coated with Zn 2 -Preparation of conductive carbon composite microspheres of W-type ferrite: using hydrothermal method and low temperature heat treatment to obtain surface coated with Zn 2 - Conductive carbon composite microspheres of W-type ferrite. Glucose is used as the precursor raw material of carbon microspheres. After a period of time in the hydrothermal reaction kettle, iron nitrate, zinc oxide, and strontium carbonate are added to continue the hydrothermal reaction to generate carbon microspheres containing Fe, Zn, and Sr on the surface. Then heat-treat the microspheres at 500-800°C to ferrite the surface and graphitize the interior, and obtain Zn-coated microspheres on the surface. 2 - Conductive carbon composite microspheres of W-type ferrite.

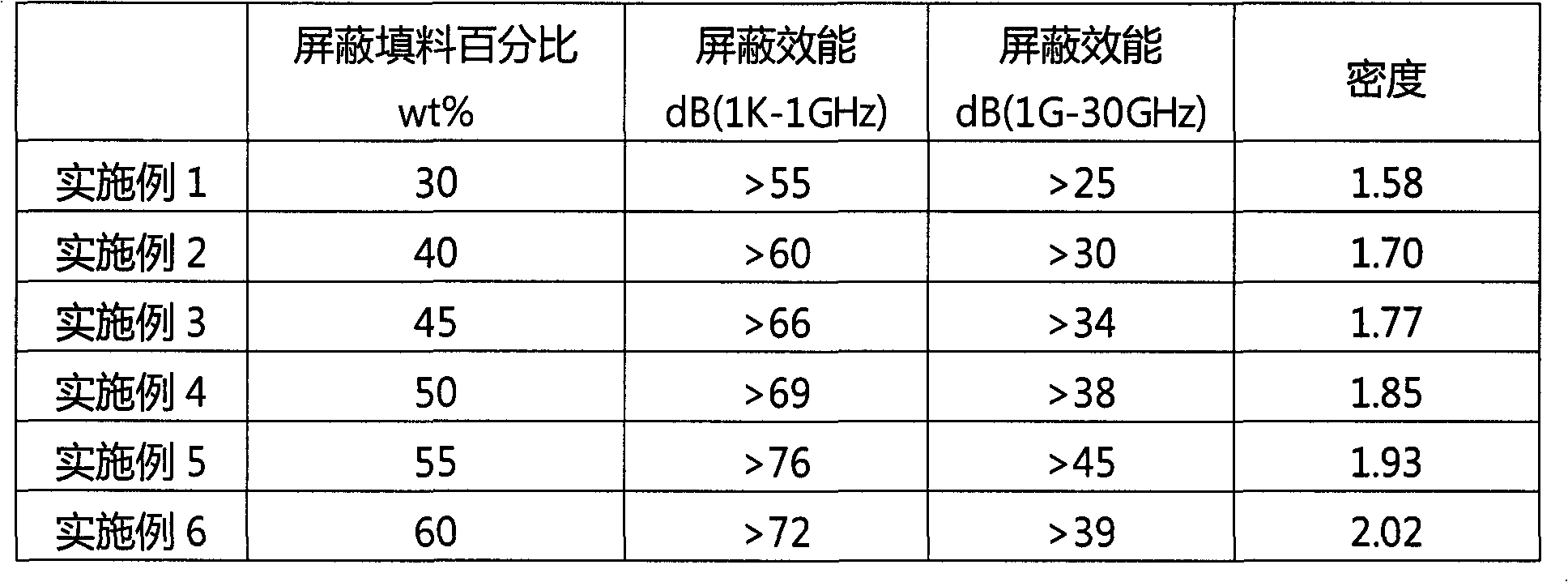

[0021] Weigh 300g, 400g, 450g, 500g, 550g, and 600g of the obtained conductive carbon composite microspheres, and add 3g, 4g, 4.5g, 5g, 5.5g, and 6g of silane coupling agent (model: KH550, Zhejiang Province ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com