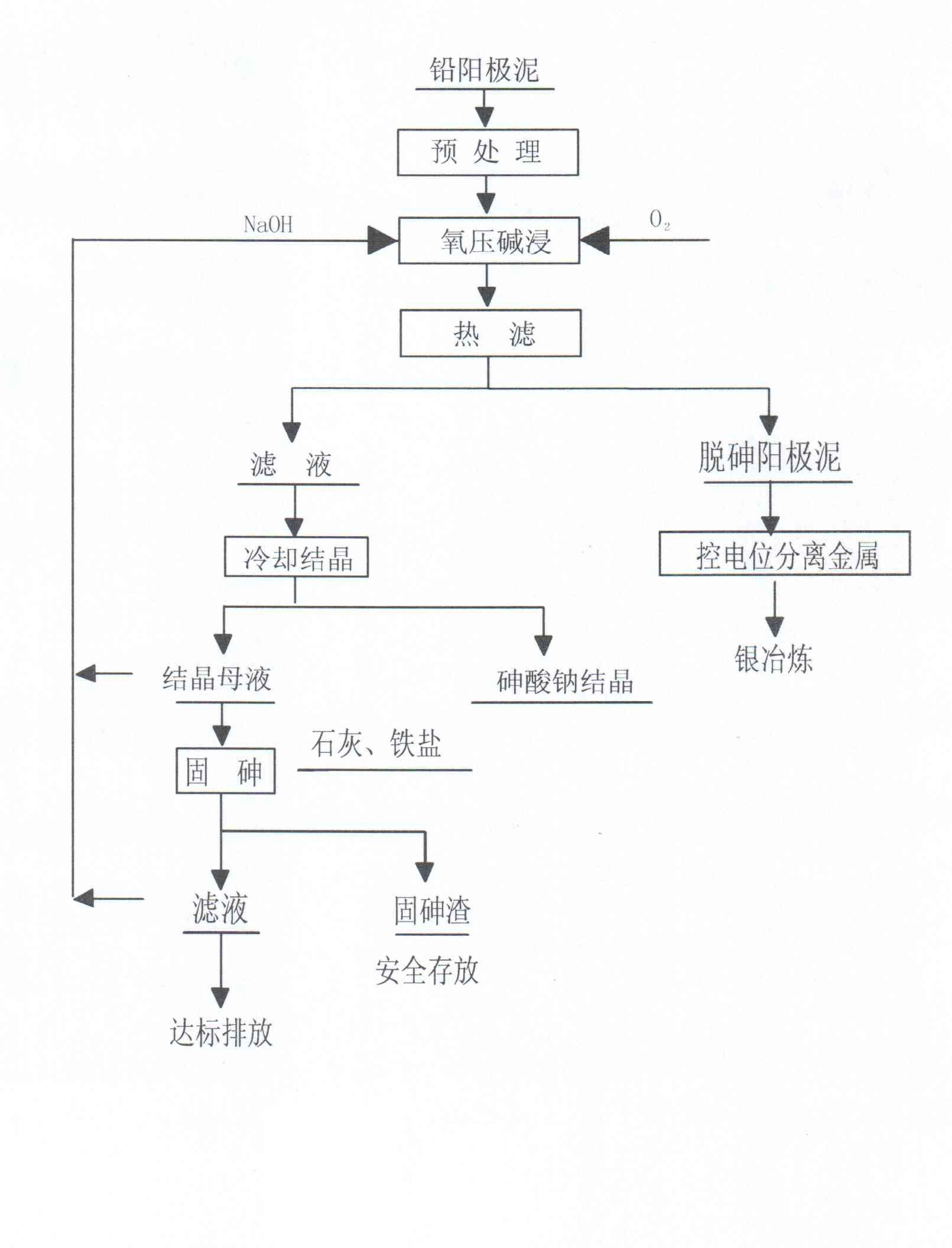

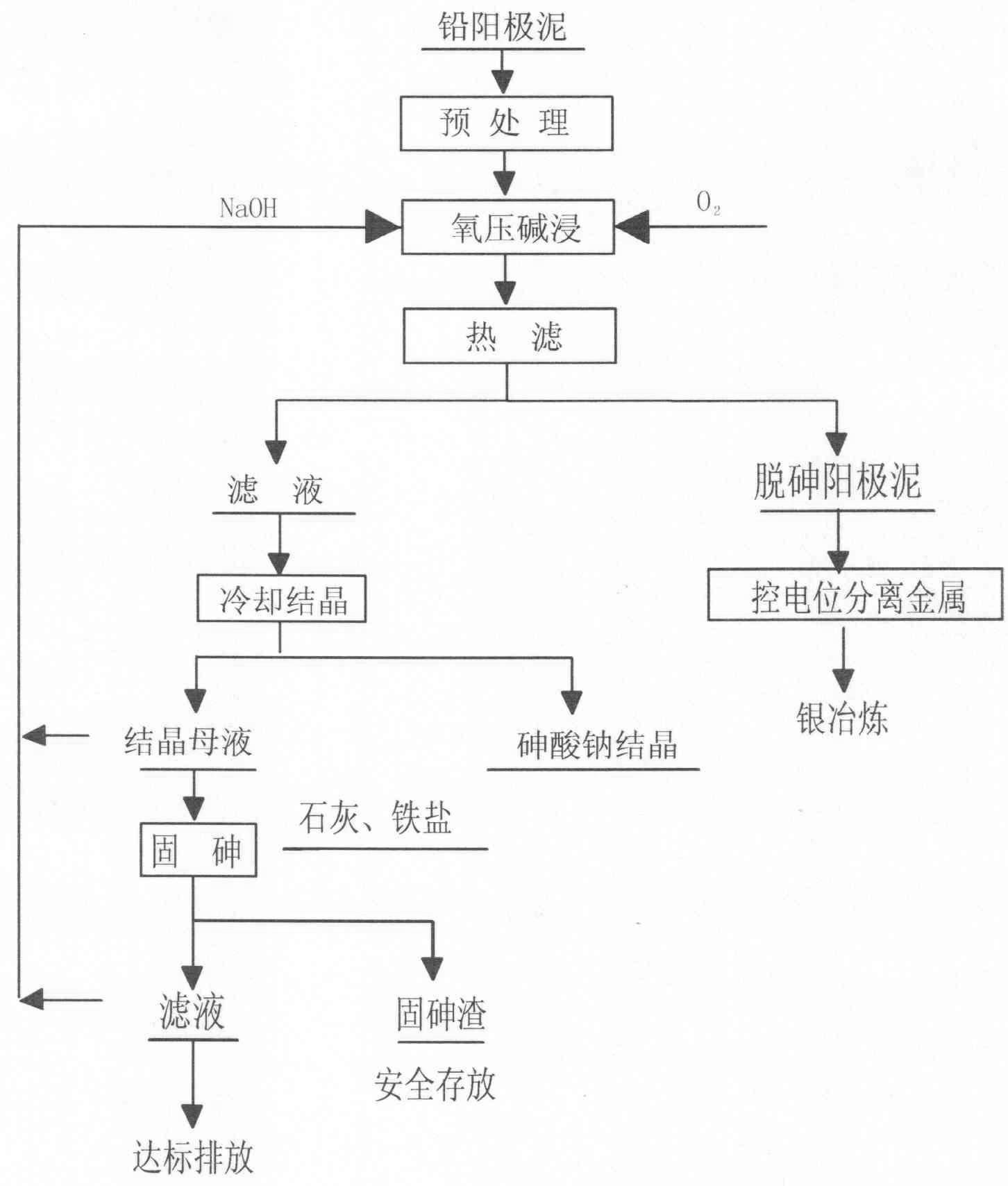

Method for dearsenicating fresh high-arsenium lead anode slime under oxygen pressure

A lead anode slime and anode slime technology, applied in the direction of improving process efficiency, to achieve the effect of strong selectivity, less impurities and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 300g of fresh high-arsenic lead anode slime and wash it with hot water at 90°C according to the solid-to-liquid ratio of 1:3 for 0.5-1.0h, and put the washed lead anode slime in an oven at 220°C for 1.0h. After the sample is cooled, the sample is prepared by ball milling, and the particle size of the ball mill is 100-120 mesh. The composition of the lead anode slime sample is Pb: 7.89; Bi: 6.62; Cu: 0.55; Sb: 38.25; As: 11.44; Ag: 6.7522; Au: 0.0062;

[0030]Take 200g of the pretreated lead anode slime sample, add tap water to make slurry according to the solid-to-liquid ratio of 1:6, and add NaOH which is 1.8 times the theoretical consumption of arsenic-antimony reaction, stir well and put it into a 2L high-pressure reactor. After confirming that the high-pressure reactor equipment is operating normally, adjust the stirring speed to 700r / min, control the reaction temperature to 180°C, the reaction oxygen pressure to 1.0MPa, and the reaction time to 2h according to...

Embodiment 2

[0034] Take 100Kg of fresh high-arsenic lead anode slime with hot water at 90°C for sizing and washing for 1.5 hours at a solid-to-liquid ratio of 1:2, and put the washed lead anode slime in an oven at 200°C for 1.5 hours. After cooling, the samples were prepared by ball milling, and the particle size of the ball mill was 100-120 mesh. The composition of the lead anode slime sample by mass percentage is: Pb: 14.33; Bi: 10.38; Cu: 0.38; Sb: 37.45; As: 12.62; Ag: 6.6559;

[0035] Take 70Kg of the pretreated lead anode slime sample, add tap water to slurry according to the solid-to-liquid ratio of 10:1, and add NaOH that is 1.6 times the theoretical consumption of arsenic-antimony reaction, and place it in 1.0m after fully stirring 3 In the high-pressure reactor, after confirming that the high-pressure reactor equipment is operating normally, adjust the stirring speed to 500r / min, control the reaction temperature to 200°C, the reaction oxygen pressure to 1.2MPa, and the reaction ...

Embodiment 3

[0039] Take 150Kg of fresh high-arsenic lead anode slime with hot water at 90°C for sizing and washing for 1.0h at a solid-to-liquid ratio of 1:4, and put the washed lead anode slime in an oven at 180°C for 1.0h. After cooling, the samples were prepared by ball milling, and the particle size of the ball mill was 100-120 mesh. The composition of the lead anode slime sample by mass percentage is: Pb: 13.2; Bi: 18.99; Cu: 0.41; Sb: 30.51; As: 12.06; Ag: 6.6676;

[0040] Take 100Kg of the pretreated lead anode slime sample, add tap water to make slurry according to the solid-to-liquid ratio of 1:7, and add NaOH which is 2.0 times the theoretical consumption of arsenic-antimony reaction, and put it into 1.0m 3 In the high-pressure reactor, after confirming that the high-pressure reactor equipment is operating normally, adjust the stirring speed to 500r / min, control the reaction temperature to 190°C, the reaction oxygen pressure to 0.8MPa, and the reaction time to 4h according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com