Robust control method for directly driving numerical control platform based on coordinate transformation and parameter adjustment

A technology of parameter adjustment and coordinate transformation, applied in the field of numerical control, can solve problems such as contour errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings.

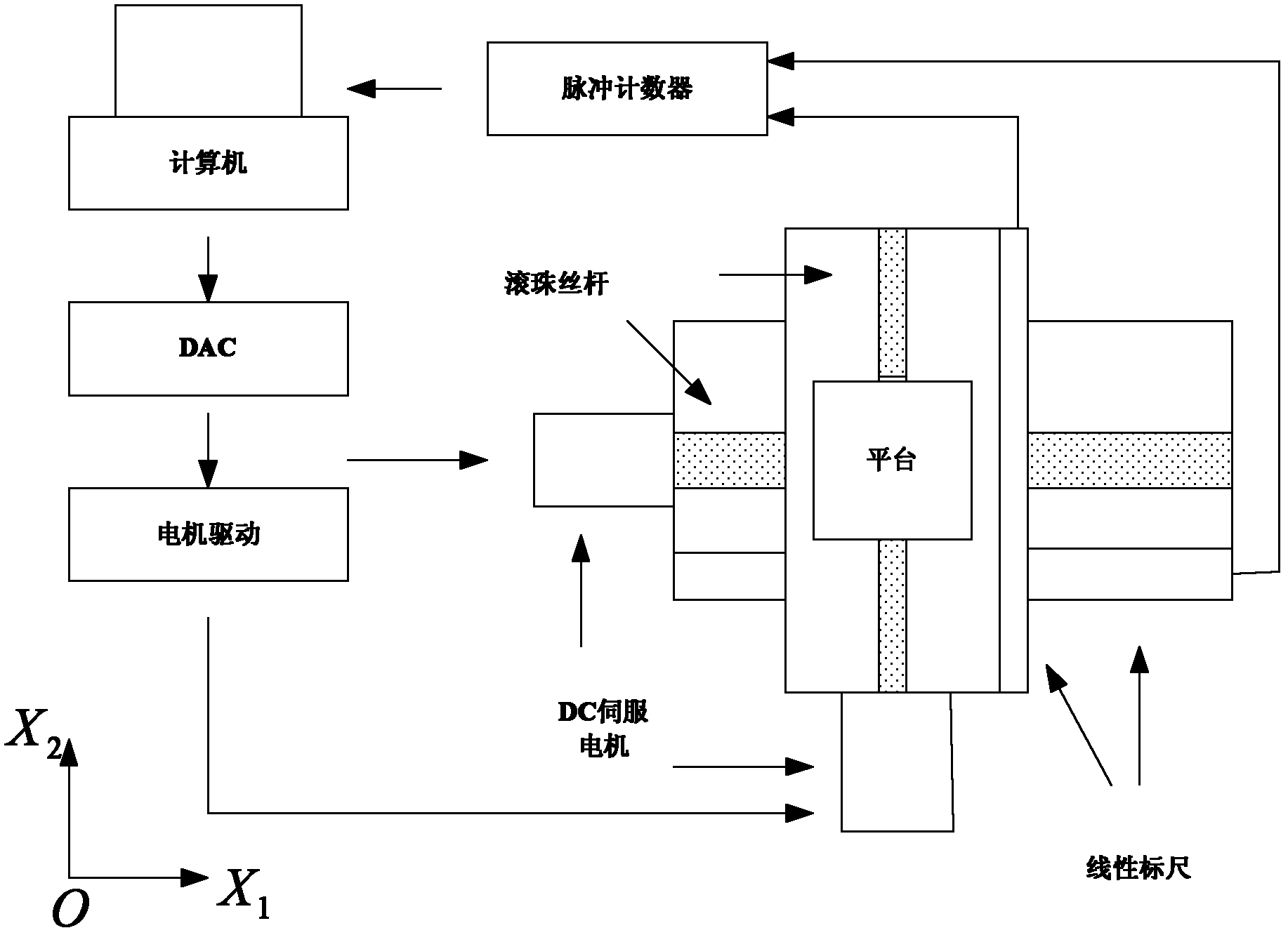

[0068] The present invention is applied to an X-Y numerical control stage with a linear drive motor, the position of the stage is connected to a linear encoder of each drive axis, and the sensor resolution of the linear encoder is 0.1 micron. The speed of each drive shaft is calculated from the reverse difference of the position measurement, and the sampling period is 2 ms.

[0069] (1) System hardware structure

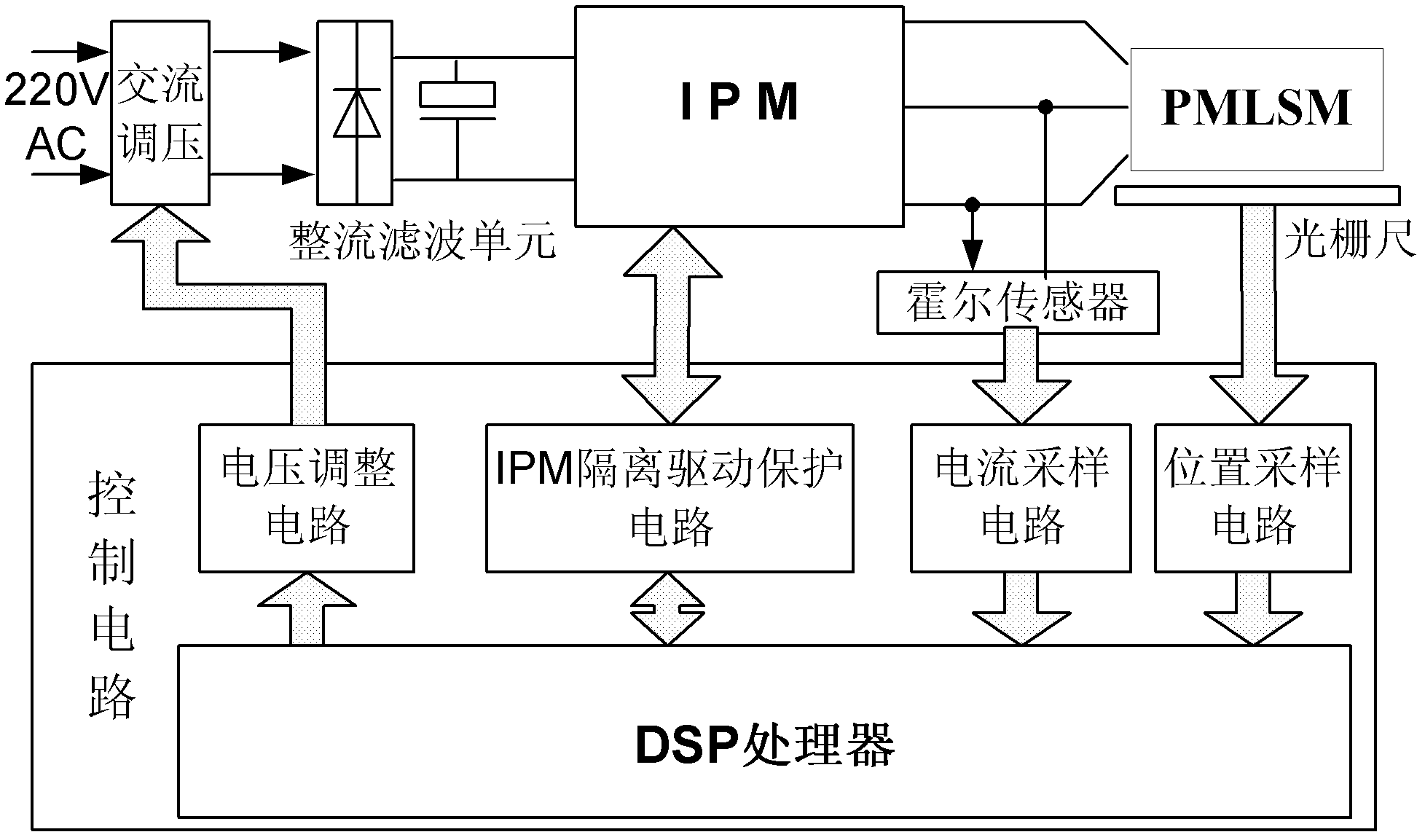

[0070] Based on coordinate transformation and parameter adjustment, the robust control system directly drives the CNC platform, including voltage adjustment circuit, rectification and filtering unit, IPM inverter unit, DSP, Hall sensor, grating scale, current sampling circuit, position sampling circuit, IPM isolation drive protection circuit . The structure of the system is as image 3 As shown, the voltage adjustment circuit adopts the reverse voltage reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com