Flue gas desulphurisation

A gas and atmosphere technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high implementation cost and insufficient removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

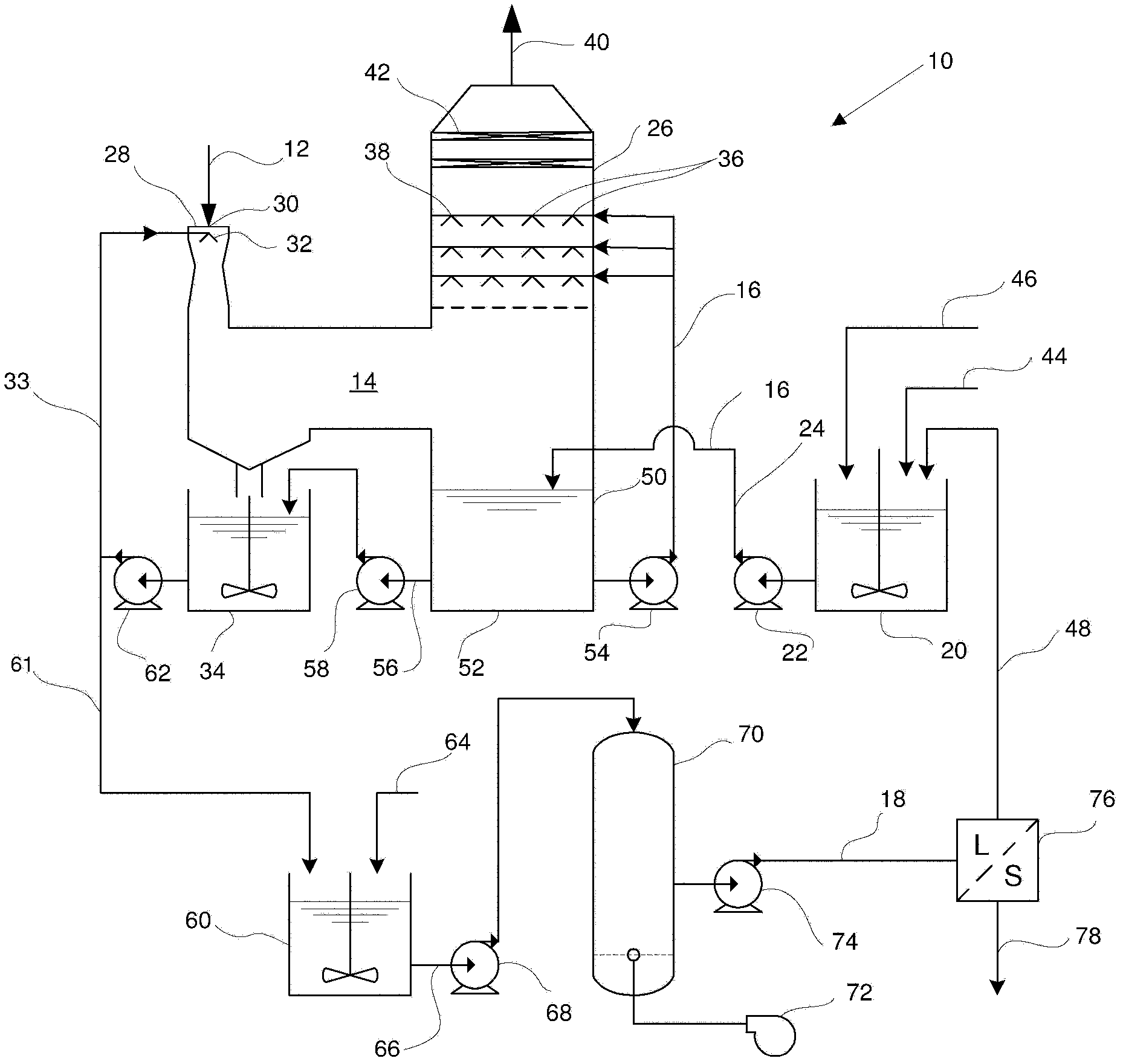

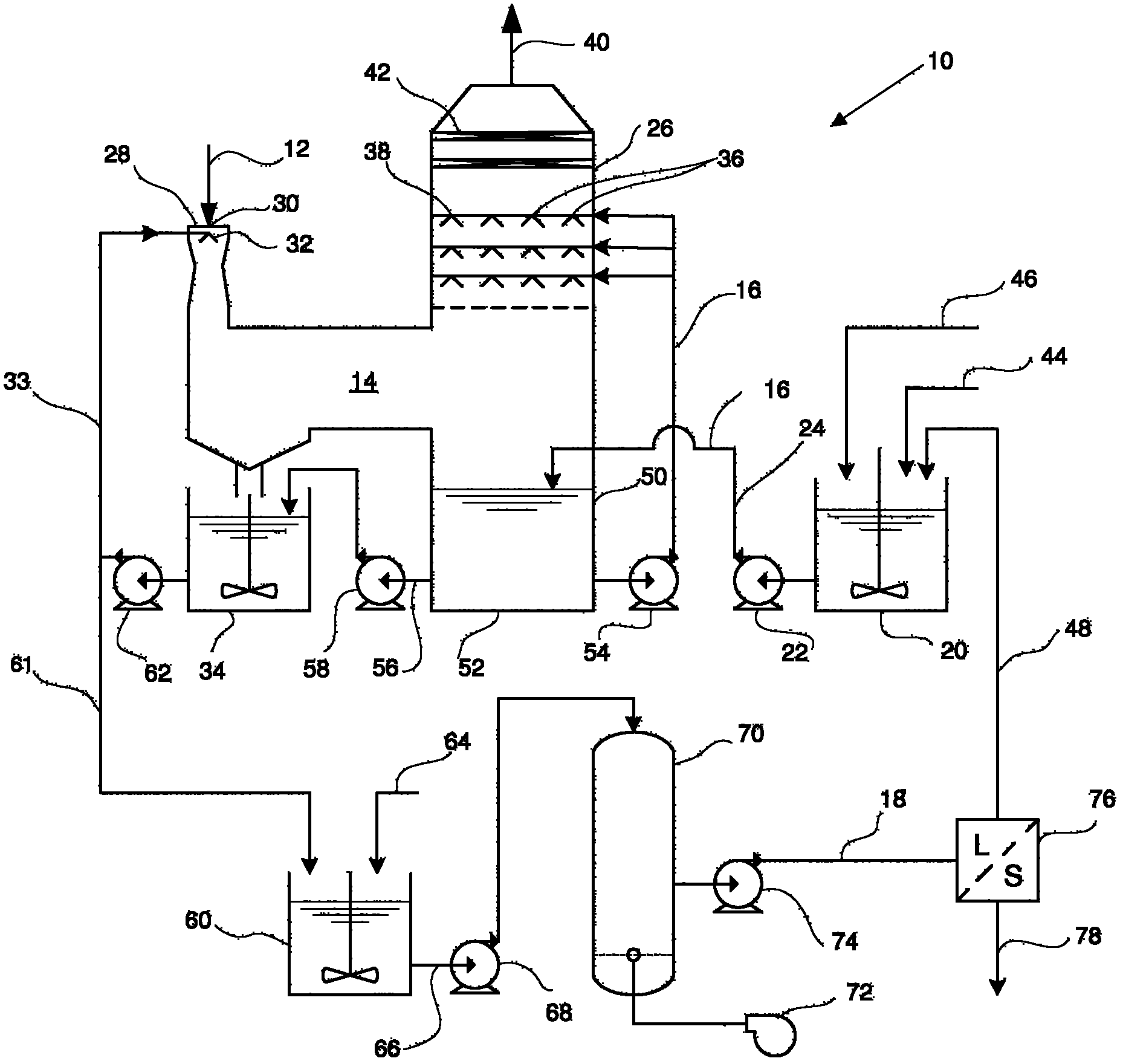

[0022] Specific embodiments of the method and system of the present invention will be described with reference to the use of TCA6 filter aid for flue gas desulfurization in alumina refineries (just an example). The invention is equally applicable to the removal of sulfur oxides from other types of gases, including flue gases and flue gases from power stations or from any stationary fossil fuel combustion facility in an alumina refinery. The terms used herein are used to describe specific embodiments only, and do not limit the scope of the present invention. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. In the drawings, it should be understood that like reference numerals refer to like parts.

[0023] The term "SO x "Refers to sulfur oxides, usually sulfur dioxide (SO 2 ) or sulfur trioxide (SO 3 ).

[0024] The term "TCA" refers to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com