Metal matrix composite materials containing carbon nanotube-infused fiber materials and methods for production thereof

A technology of carbon nanotubes and composite materials, which is applied in the direction of nanotechnology, carbon compounds, nanotechnology, etc., and can solve problems that have not yet contained nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

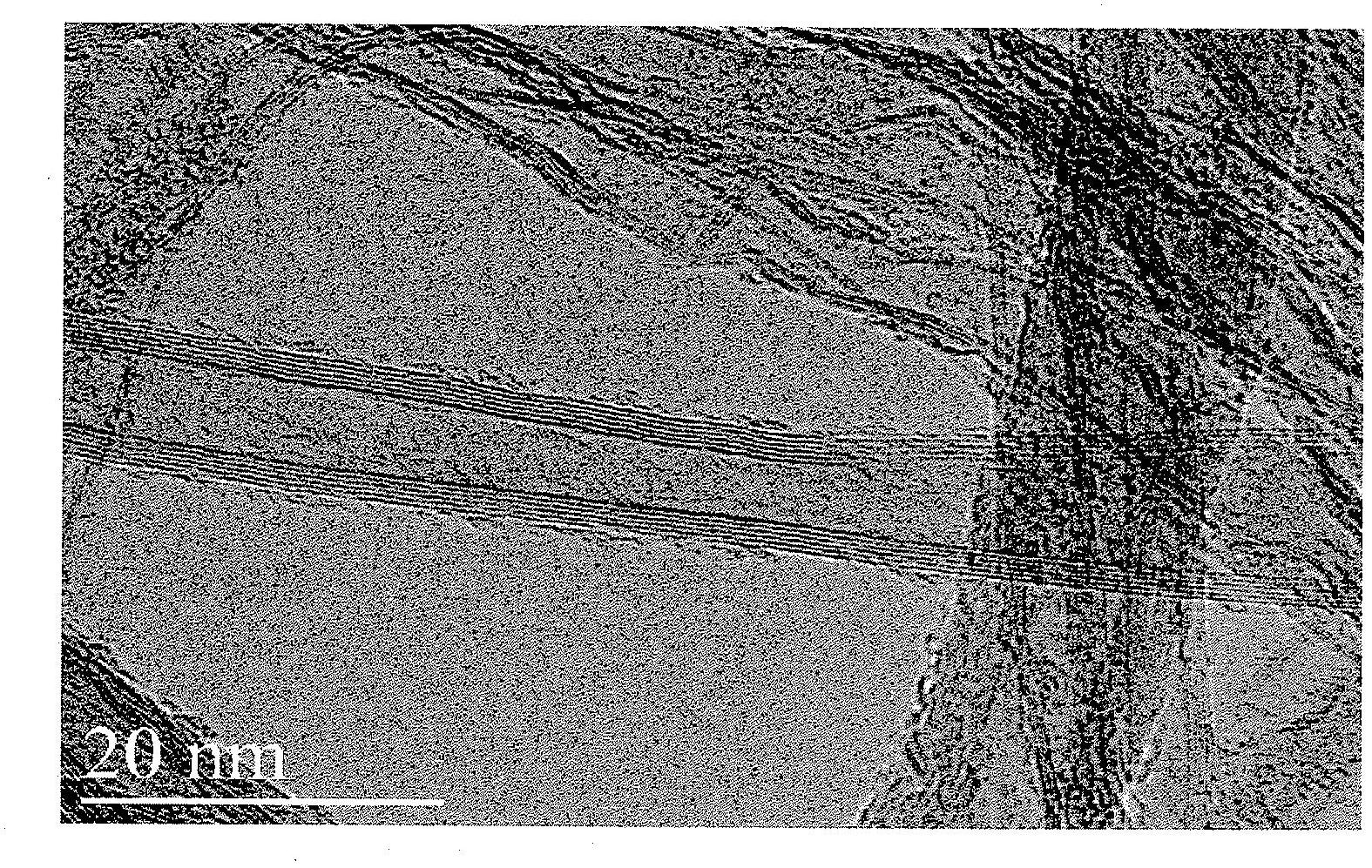

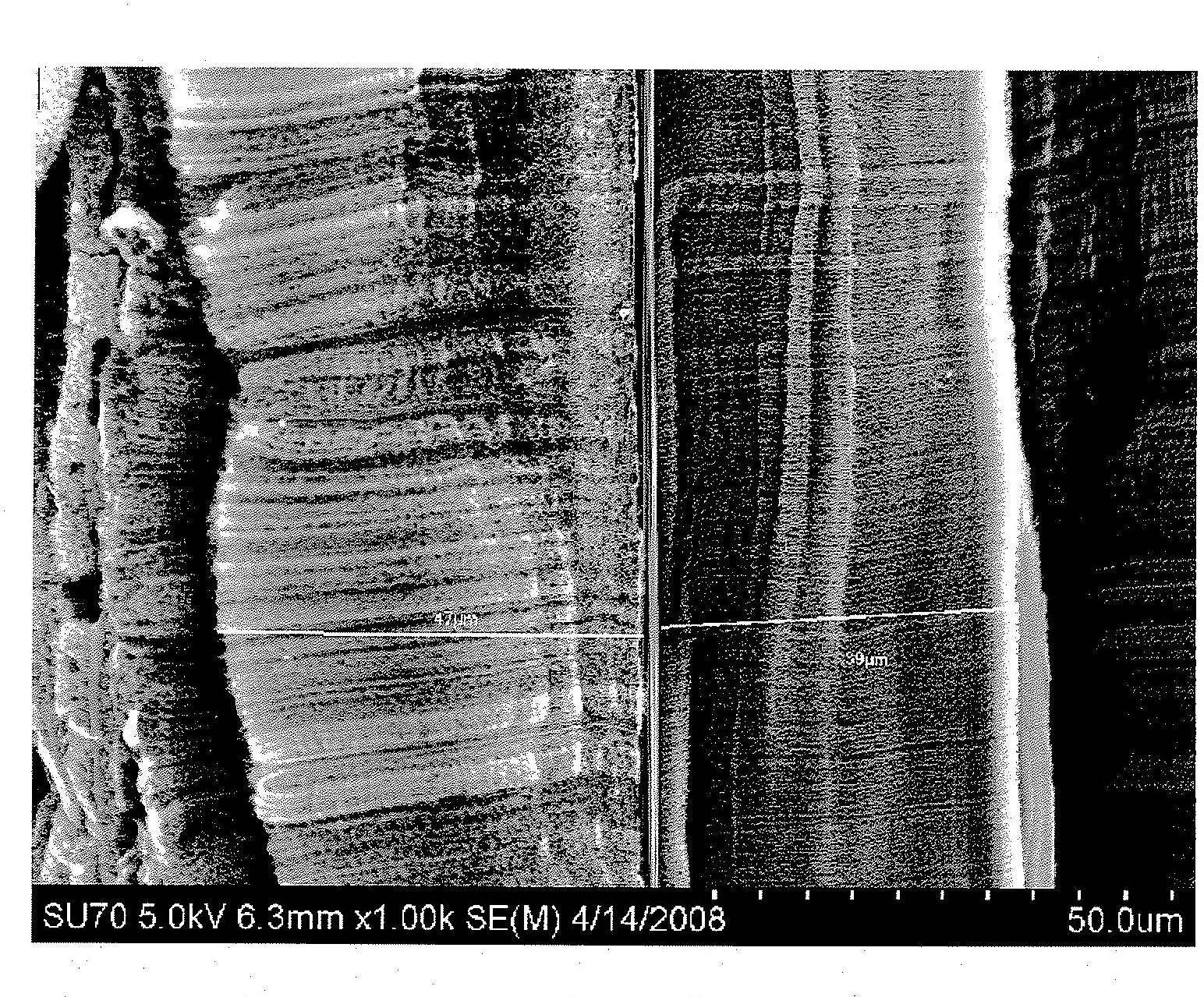

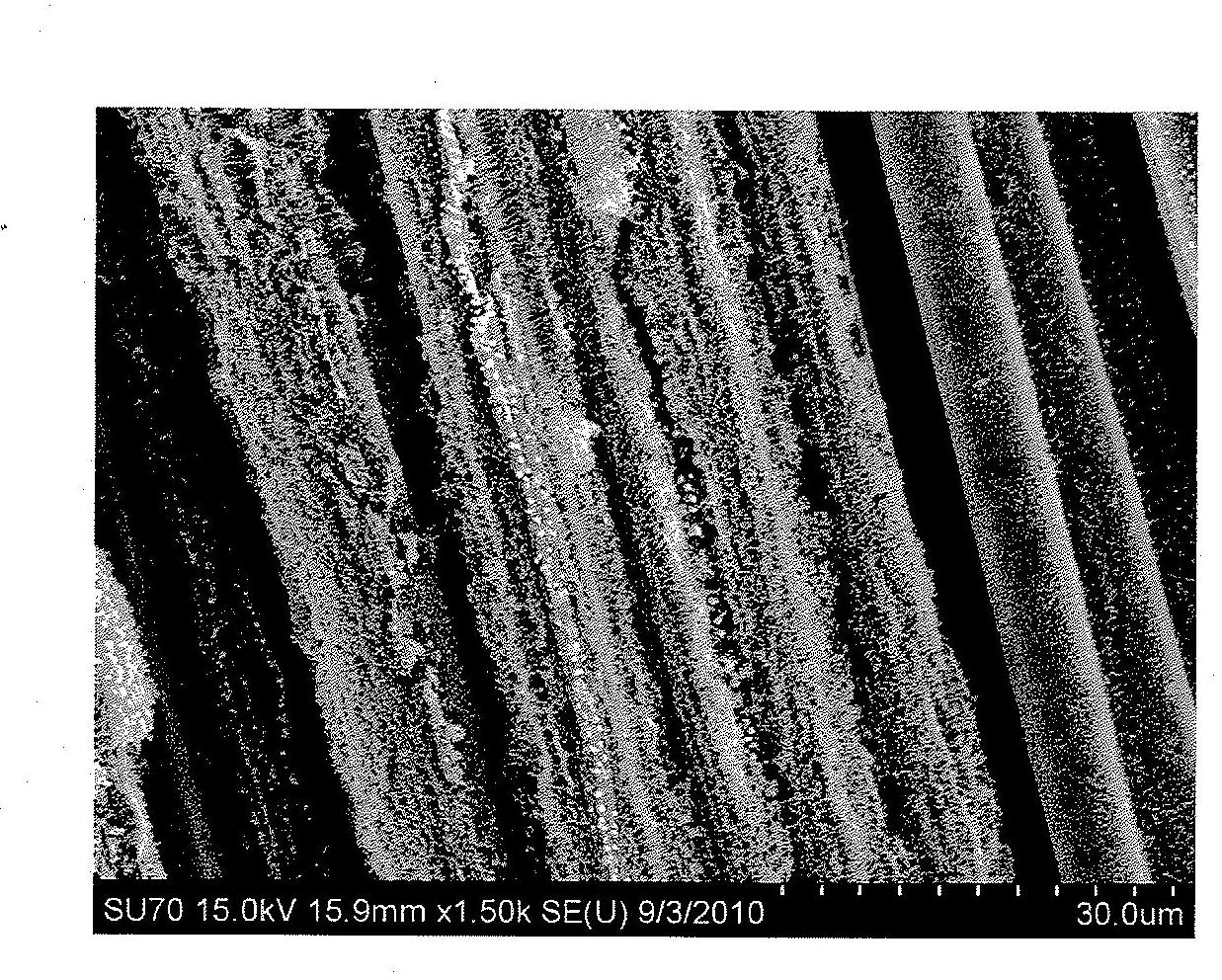

[0133]Example 1: Formation of an aluminum metal matrix composite with a reduced coefficient of thermal expansion. Aluminum metal matrix composites were prepared by liquid metal infiltration of carbon nanotube-infused carbon fibers. The carbon fibers were Grafil, Inc. (Sacramento, CA) 34-700, 12k filaments infused with carbon nanotubes with an average length of 55 μm prepared by the continuous infusion method described above. Metal matrix composites were prepared in a pressure tight chamber comprising a heated infiltration vessel with the form placed on the bottom. Carbon nanotube-infused carbon fibers were placed on the bottom of the model in a unidirectional arrangement to prepare test bricks. The aluminum source was placed on top of the carbon nanotube-infused carbon fibers in the model. The aluminum source is aluminum alloy Al413, whose composition is Al 12 Si 2 FeCu 0.5 Ni 0.5 Zn 0.35 Mn. Vacuum was applied to the chamber and the infiltration vessel was heated to 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com