Novel reaction kettle for producing methylamino avermectin benzoate

A technology of methylamino abamectin and benzoate, applied in the field of reactors, can solve problems such as shortening reaction time, and achieve the effect of improving heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

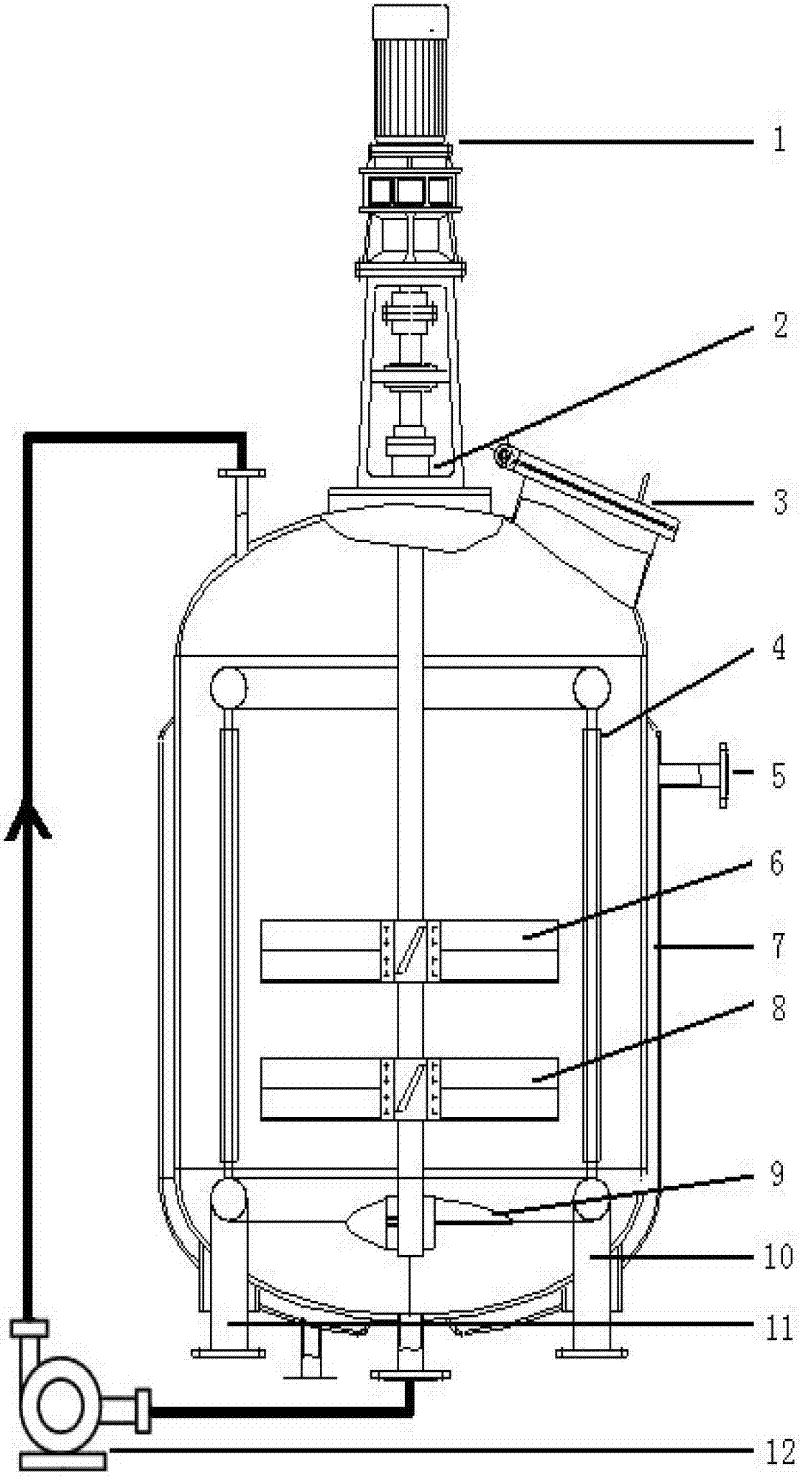

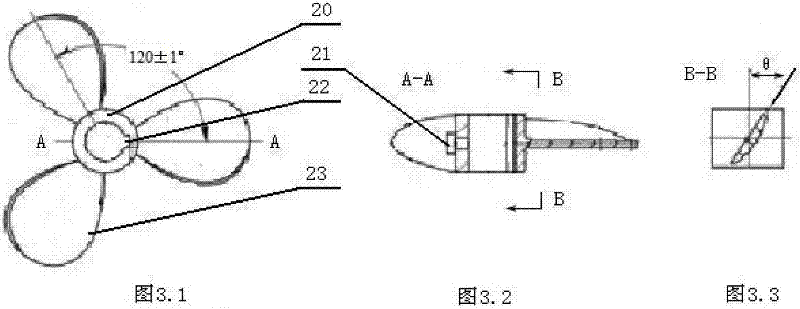

[0044] A reaction kettle for the production of emamectin benzoate, that is, a reactor for C-5 protection reaction, C-4 oxidation reaction, and C-4 reduction reaction. The agitator is divided into three layers, and the bottom is stirred The device is a three-blade propulsion type agitator, and the first and second layers above (that is, the upper layer agitator and the middle layer agitator) are both two-blade oblique paddle type agitators; It is connected and equipped with a vertical circulation pump to improve the effect of vertical circulation so as to fully mix the materials.

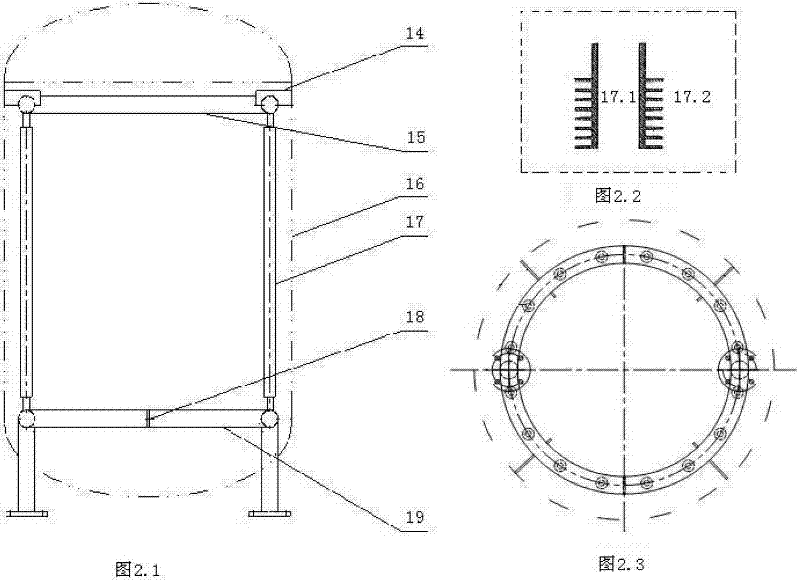

[0045] For the new reactor described above, the outer wall of the kettle is provided with a jacket 7, the bottom of the jacket of the outer wall of the kettle is provided with a refrigerant inlet 12, and the upper part of the jacket is provided with a refrigerant outlet 5; the bottom of the kettle is provided with a lower general ring pipe 19 , the cooling finned tube refrigerant inlet 10 and the coo...

Embodiment 2

[0056] Application of new reactor for C-4 reduction reaction: agitator drive motor power 5.5KW; cooling finned tubes 16 groups, finned tube base tube outer diameter 38mm, thickness 3.5mm, fin outer diameter 60mm, fin pitch 6mm, fin thickness 1mm, each group length 120mm, outer diameter of the upper and lower total ring pipes 76mm, source: self-made;

[0057] The upper stirrer and the middle stirrer are two-blade oblique paddle stirrers, with a stirring diameter of 800mm, a blade width of 65mm, a key width of 18mm, and fixing bolts M20; source: Zhejiang Great Wall Reducer Co., Ltd.;

[0058] The bottom agitator is a three-blade propulsion agitator with a stirring diameter of 650mm, a key width of 18mm, and a fixing bolt of M20. Source: Zhejiang Great Wall Reducer Co., Ltd.;

[0059] Reactor effective volume 2m 3 ;

[0060] The above accessories are made of stainless steel 304;

[0061] The longitudinal circulation pump is: an explosion-proof magnetic pump with a suction inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com