Thermal-insulation ceramic and thermal-insulation ceramic coating

A ceramic and pink technology, applied in the direction of reflection/signal coating, coating, application, etc., can solve the problems of unfavorable product quality stability, high cost, etc., achieve obvious heat insulation effect, simple production formula, and no safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

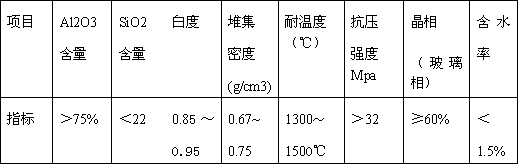

[0035] Table 3: The weight percent of each component of heat-insulating ceramics and the sintering temperature and time for Examples 1-3

[0036]

[0037] According to the process ratio in Table 3, mix Jiepai peach red mud, Donghu mud and Changfeng kaolin in proportion, stir, then gradually add alumina powder, rare earth oxides, mineralizers in order, fully stir and mix to make porcelain mud, After passing through an extruder, it is extruded into mud sticks, dried, put into a sagger and put into a kiln. At a temperature of 1050-1400°C, it is continuously heat-preserved and sintered for 40-80 hours, and then naturally cooled out of the kiln. After leaving the kiln, the porcelain sticks Grinding and processing into 300-mesh powder can make heat-insulating ceramic powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com