Natural gas desulfurization process

A desulfurization process, natural gas technology, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of sulfur blockage, few successful cases, etc., to achieve the effect of fast absorption, convenient operation, and reduced amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

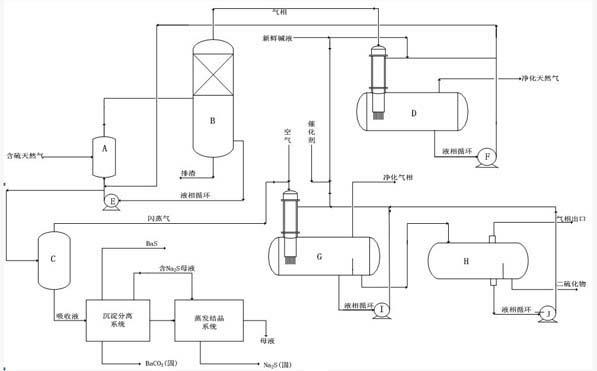

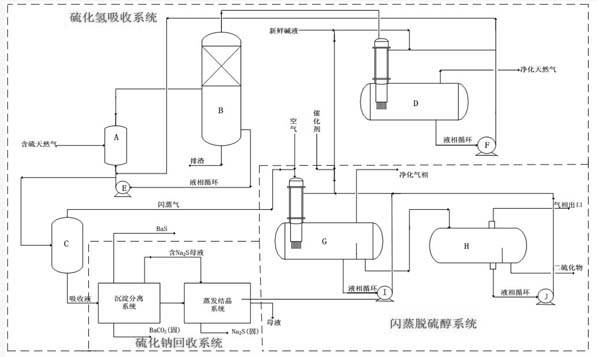

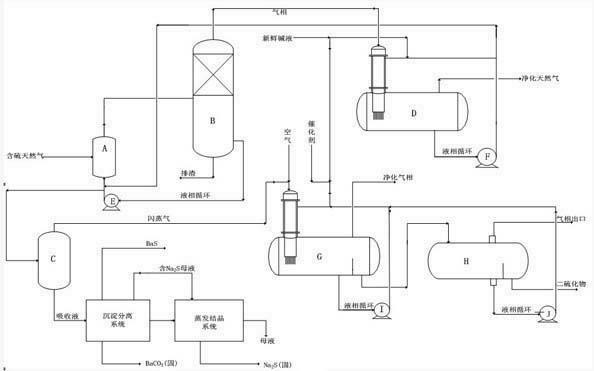

[0046] Step 1, hydrogen sulfide absorption: containing hydrogen sulfide 0.81% (mol / mol), carbon dioxide 5.11% (mol / mol), methyl mercaptan 0.0029% (mol / mol), pressure 1.0mpa, flow rate 1000 standard cubic meters per hour The natural gas, the circulating lye (50m3 / hour) from the lye circulation pump E and the lye (5m3 / hour) from the circulation pump F are in the gas-liquid mixer A (empty tower spray mixer, diameter 1000mm, 6000mm in height) and mixed in the gas-liquid separator B, the pre-desulfurized natural gas coming out of separator B (packing type separator, diameter 1000mm, height 8000mm, gas and liquid enter from the middle, the upper and lower parts have 2000mm high packing respectively) Enter the fiber membrane desulfurization reactor D (fiber membrane desulfurization reactor D is a fiber membrane liquid-liquid mass transfer reactor, its structure and reaction principle refer to the patent US 3992156 ; wherein the diameter of the fiber membrane part is 1000mm, the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com