Polyethylene naphthalate(PEN)/polyphenylene sulfide (PPS) blend filament and preparation method thereof

A technology of polyethylene naphthalate and polyphenylene sulfide, applied in the direction of single-component polyester rayon, conjugated synthetic polymer rayon, rayon manufacturing, etc., can solve the problem of PPS fiber Expensive and other issues, to achieve the effect of increasing production efficiency, broad application prospects, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Vacuum-dry the polyethylene naphthalate slices at 220°C for 6 hours, and dry the polyphenylene sulfide slices at 220°C for 4 hours;

[0025] (2) The above-mentioned two kinds of dry slices are sent into a twin-screw blending extruder according to the weight percentage of polyethylene naphthalate at 95%, and the precursors are blended and melt-spun, and the melting temperature is 268° C. , the time is 30min;

[0026] (3) Draw the above-mentioned raw silk, the drawing temperature is 220°C, the drawing ratio is 3, and finally it is packaged at 1000m / min to obtain the polyethylene naphthalate / polyphenylene sulfide blend length Silk.

Embodiment 2

[0028] (1) Vacuum-dry the polyethylene naphthalate slices at 220°C for 6 hours, and dry the polyphenylene sulfide slices at 220°C for 4 hours;

[0029] (2) The above-mentioned two kinds of dry chips are sent into a twin-screw blending extruder according to the weight percentage of polyethylene naphthalate at 97%, and blended and melt-spun to make precursors, and the melting temperature is 285° C. , the time is 60min;

[0030] (3) Draw the above-mentioned raw silk, the drawing temperature is 245°C, the drawing ratio is 5, and finally it is packaged at 1500m / min to obtain the polyethylene naphthalate / polyphenylene sulfide blend length Silk.

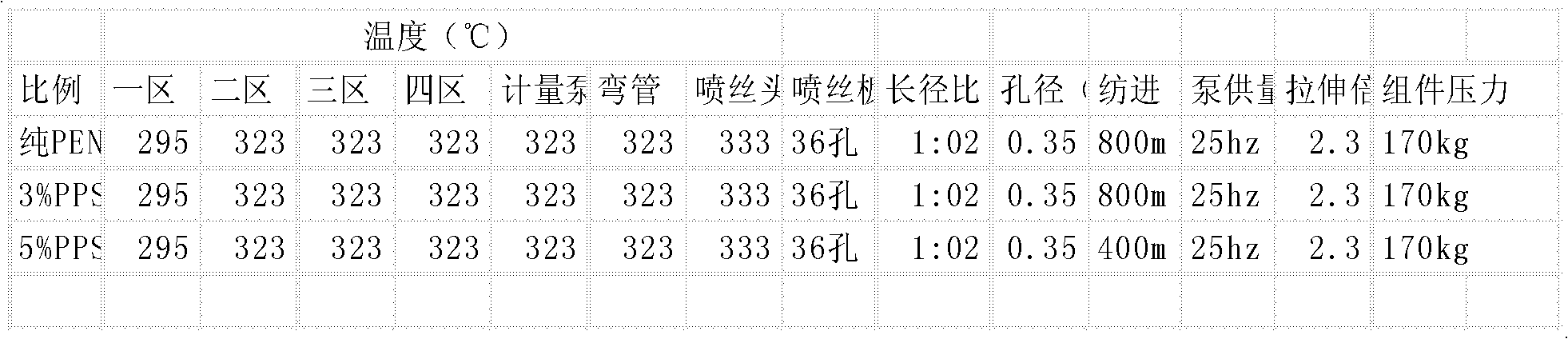

[0031] The specific process parameters are shown in Table 1:

[0032] The concrete process parameter of table 1 embodiment 1 and 2

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com