Air compressor hybrid control system and method

A gas compressor and hybrid control technology, applied in the field of control systems, can solve problems such as unfavorable fault hidden dangers, timely resolution of unfavorable faults, failure of the main controller to reflect abnormal states in time, and failure of the main controller to reflect in time, so as to ensure stability and optimality. Efficiency, improved safety and mean time between failures, reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

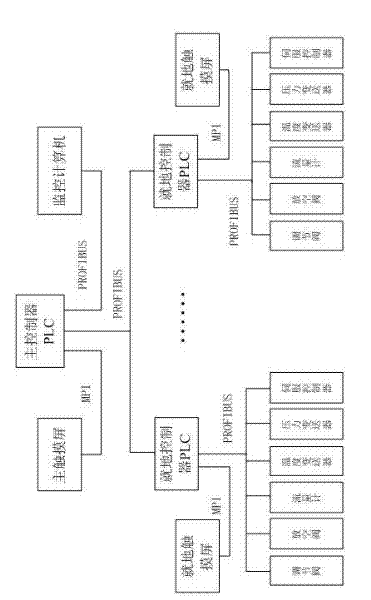

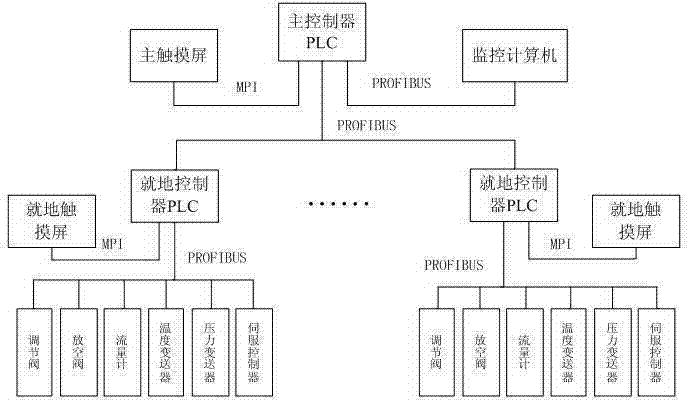

[0025] Embodiment 1, with reference to figure 1 , a hybrid control system for a gas compressor,

[0026] The system includes the main controller PLC and several local controller PLCs;

[0027] The main controller PLC is connected to the main touch screen through the MPI bus, and connected to the monitoring computer through the PROFIBUS bus; each local controller PLC is connected to the main controller PLC through the PROFIBUS bus;

[0028] Each local controller PLC is connected to a local touch screen through the MPI bus, and is connected to a regulating valve, vent valve, flow meter, temperature transmitter, pressure transmitter and servo on a gas compressor through the PROFIBUS bus. Controller connection.

Embodiment 2

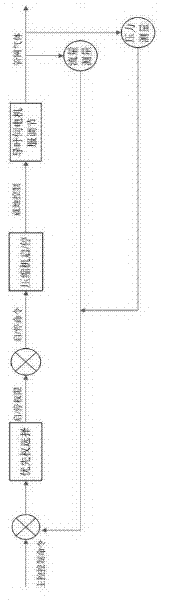

[0029] Embodiment 2, with reference to figure 1 , 2, a mixing control method for a gas compressor,

[0030] The method uses the mixing control system described in Embodiment 1 to carry out mixing control;

[0031] Before the hybrid control system is started, a gas flow value is preset in the main controller PLC according to the specific working conditions. When the system is started, the main controller PLC performs cyclic scanning to detect whether there is a fault before each gas compressor starts; when the system is running According to the comparison between the measured value and the set value, it is determined whether to start the next gas compressor, and the output power of the gas compressor is adjusted by using the conventional PID control algorithm; the operation of the compressor unit is controlled by adjusting the opening of the inlet guide vane of the gas compressor Efficiency, in the remote control mode, the main controller PLC adopts intelligent constant pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com