Photoelectric continuous liquid level measuring method and device

A liquid level measuring device and a technology for liquid level measurement, which are applied to measuring devices, liquid/fluid solids measurement, lubrication indicating devices, etc., can solve problems such as inability to perform accurate liquid level measurement, and achieve convenient maintenance, free assembly, and convenient transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

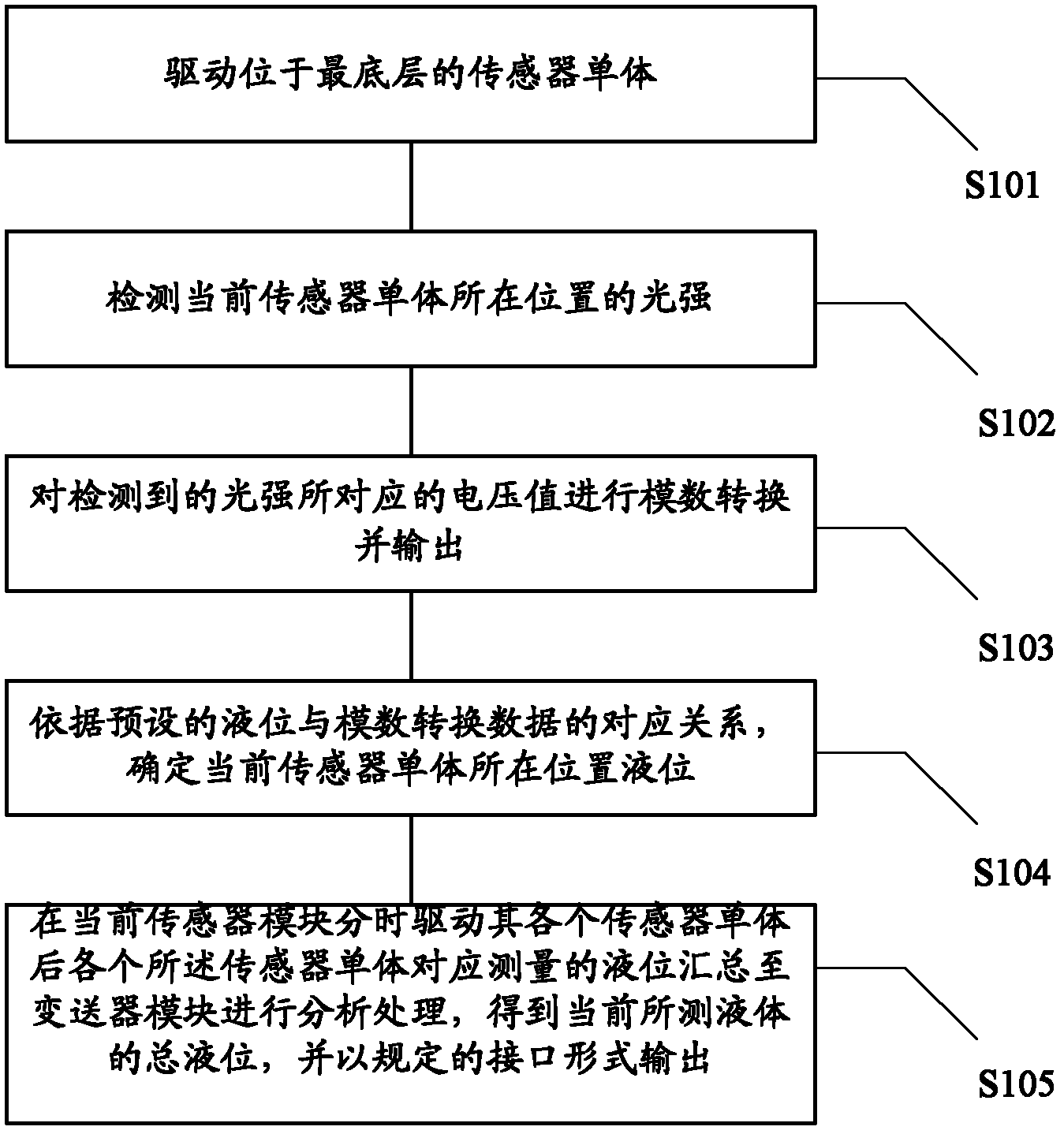

[0081] Based on the above core idea, the first embodiment specifically discloses a photoelectric continuous liquid level measurement method performed by a photoelectric continuous liquid level measurement device based on a sensor module composed of cascaded N sensor units. Wherein, N is greater than or equal to 1, the specific process of the method is as follows figure 1 As shown, it mainly includes the following steps:

[0082] Step S101, driving the sensor unit at the bottom;

[0083] Step S102, detecting the light intensity at the position of the current sensor unit;

[0084] During the execution of step S102, when driving from bottom to top, the current sensor unit is the sensor unit currently in the driving state.

[0085] Step S103, performing analog-to-digital conversion and outputting the voltage value corresponding to the detected light intensity;

[0086] In the process of executing step S103, when the current sensor unit is driven to detect the light intensity at...

Embodiment 2

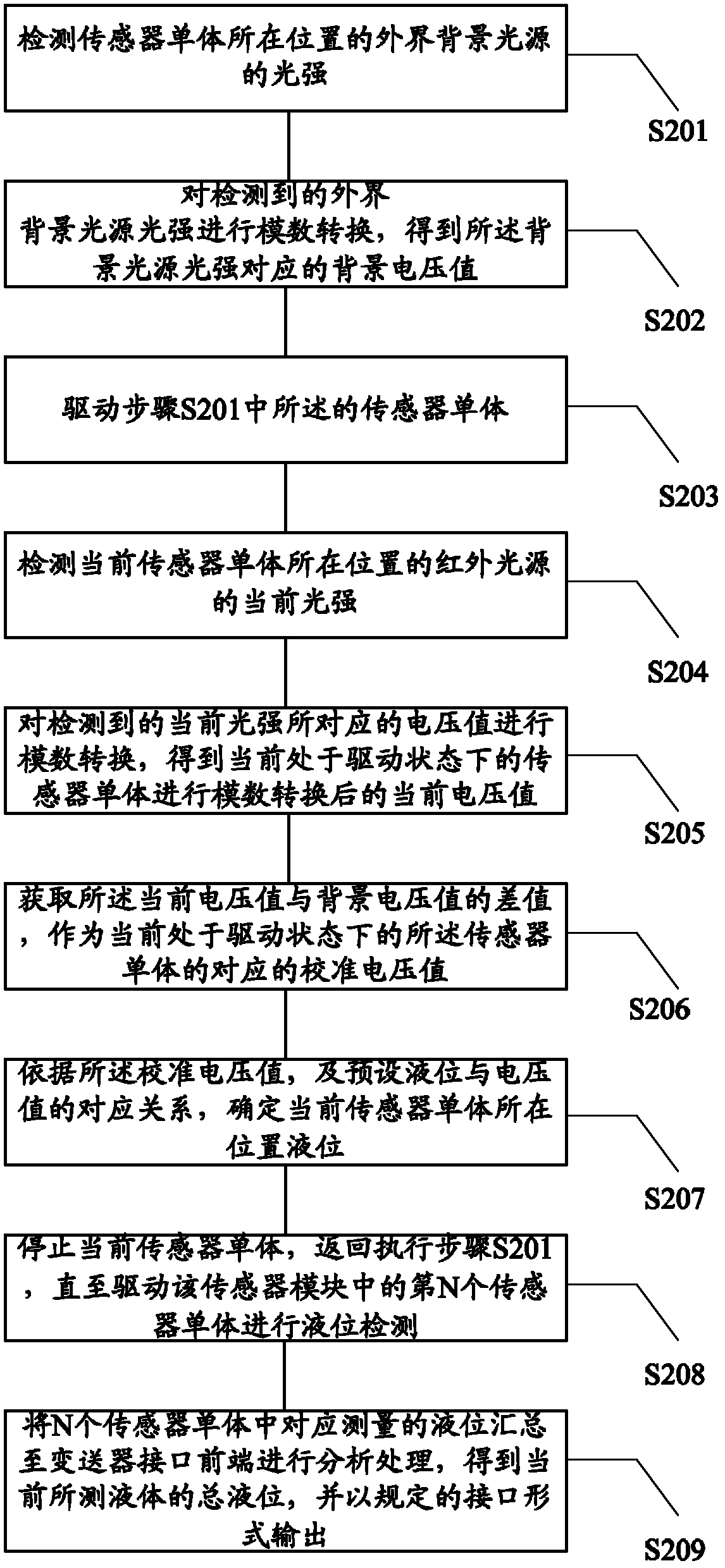

[0093] Based on the method of the first embodiment above, in the actual measurement process using the photoelectric continuous liquid level measuring device, the data obtained by analog-to-digital conversion contains two parts of the effect of light on the phototransistor: one part is the infrared LED light source, which is The other part of the useful signal is the background light source of the external environment. If there is fluctuation in this part of the light source, it will affect the measurement result, and we need to filter it out. Therefore, in order to avoid the influence of the light intensity of the background light source on the process of continuously measuring the liquid level. The second embodiment of the present invention, on the basis of the above-mentioned embodiments, is based on a photoelectric continuous liquid level measuring device based on a sensor module composed of N sensor monomers cascaded, wherein N is a positive integer greater than or equal to...

Embodiment 3

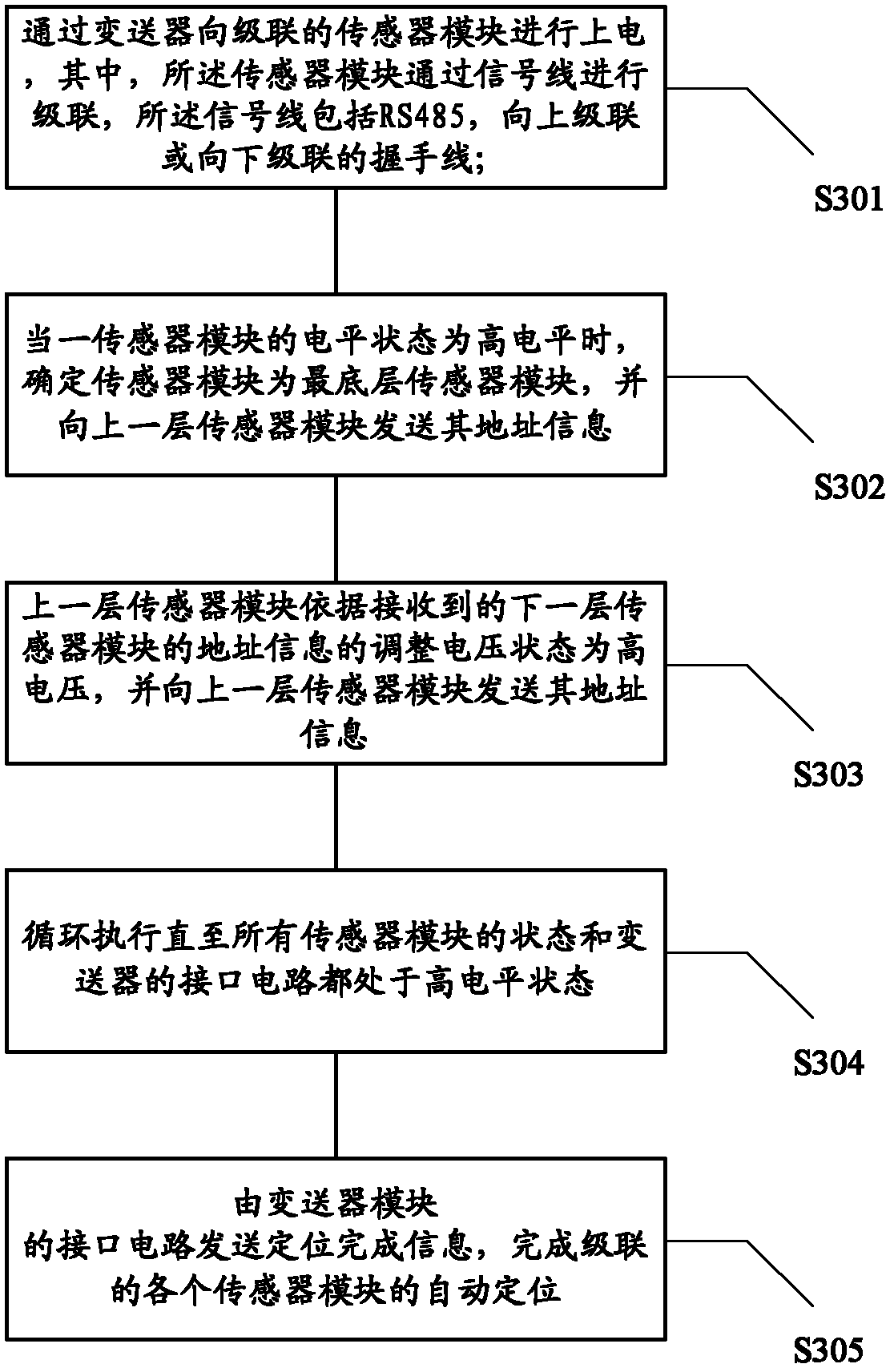

[0106] Based on the methods of the above embodiments, in actual use, the height of the carrier to be measured on-site is about 30 cm to 200 cm, and the height is not certain. The adopted sensor module cannot be assembled according to the measuring range when leaving the factory, and the sensor module assembled into a measuring range of 200 centimeters is also inconvenient to transport.

[0107] Therefore, when the measuring range of the required liquid level is relatively large, cascade connection of multiple sensor modules can be used for continuous liquid level measurement. When there are two or more cascaded sensor modules in the photoelectric continuous liquid level measuring device, this embodiment of the present invention discloses an automatic positioning method during the process of assembling the sensor modules, the process of which is as follows image 3 As shown, it mainly includes the following steps:

[0108] Step S301, supplying power to the cascaded sensor modu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com