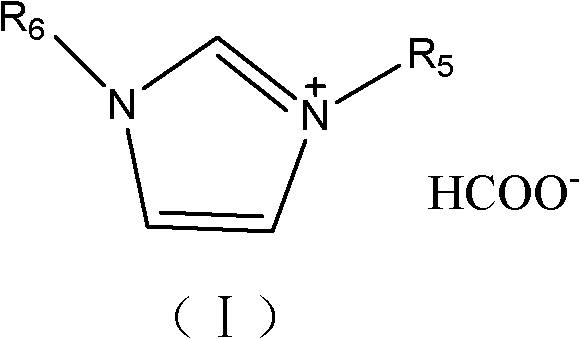

Ionic liquid electrolyte

An ionic liquid and electrolyte technology, applied in electrolytic capacitors, circuits, capacitors, etc., can solve the problems of low efficiency and instability of ion transport batteries, and achieve the effect of improving overall stability, solving volatility and non-volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

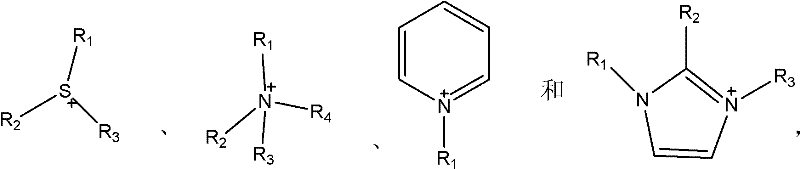

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the preparation of ionic liquid electrolyte

[0035] 0.0013g LiI was added to 1-methyl-3-allyl imidazole carboxylic acid of 100ul, stirred to make LiI dissolve, then added 0.0025g iodine (I2 ), stirring it to dissolve, to obtain formic acid ionic liquid electrolyte; in this ionic liquid electrolyte, the molar concentration of LiI is 0.1molL -1 , I 2 The molar concentration is 0.1molL -1 .

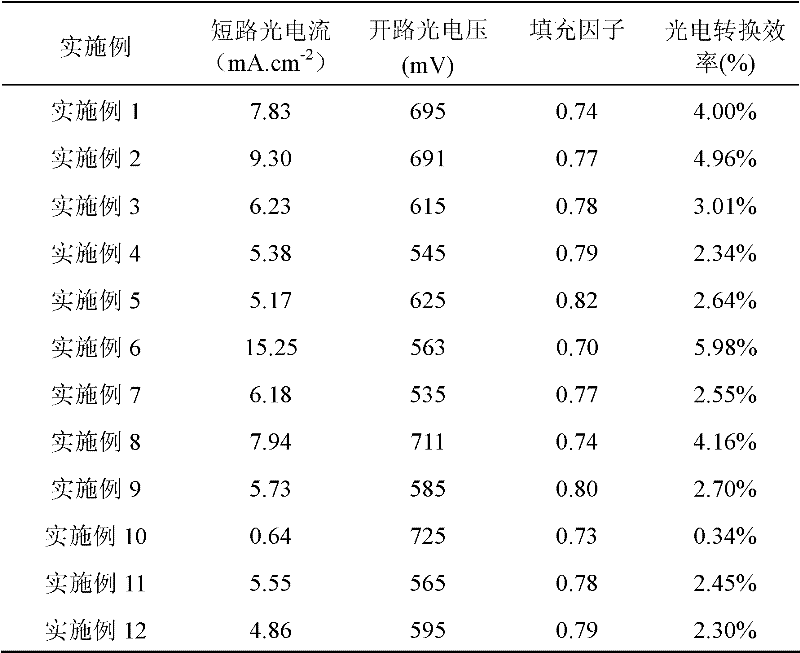

[0036] The above-mentioned formic acid ionic liquid electrolyte was assembled into a dye-sensitized solar cell, and the photoelectric parameters of the cell were measured in Table 1.

Embodiment 2

[0037] Embodiment 2, the preparation of ionic liquid electrolyte

[0038] 0.0039g LiI is added in the 1-methyl-3-allyl imidazole carboxylic acid of 100ul, stirs to make LiI dissolve, then adds 0.0025g iodine (I 2 ), stirring it to dissolve, to obtain formic acid ionic liquid electrolyte; in this ionic liquid electrolyte, the molar concentration of LiI is 0.3molL -1 , I 2 The molar concentration is 0.1molL -1 .

[0039] The above-mentioned formic acid ionic liquid electrolyte was assembled into a dye-sensitized solar cell, and the photoelectric parameters of the cell were measured in Table 1.

Embodiment 3

[0040] Embodiment 3, the preparation of ionic liquid electrolyte

[0041] 0.0045g NaI is added in the 1-methyl-3-allylimidazole formic acid of 100ul, stirs and NaI is dissolved, then adds 0.0025g iodine (I 2 ), stirring it to dissolve, to obtain formic acid ionic liquid electrolyte; in this ionic liquid electrolyte, the molar concentration of NaI is 0.3molL -1 , I 2 The molar concentration is 0.1molL -1 .

[0042] The above-mentioned formic acid ionic liquid electrolyte was assembled into a dye-sensitized solar cell, and the photoelectric parameters of the cell were measured in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com