Block type high-temperature-resistant copolyamide and preparation method thereof

A technology of copolyamide and block copolymer, which is applied in the field of block-type high-temperature-resistant copolyamide and its preparation, can solve the problems that the degree of reaction cannot be further improved, it is not suitable for industrial production, and the scope of application is limited, so as to facilitate mass production and broaden the scope of application. The effect of convenient application and aggregation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

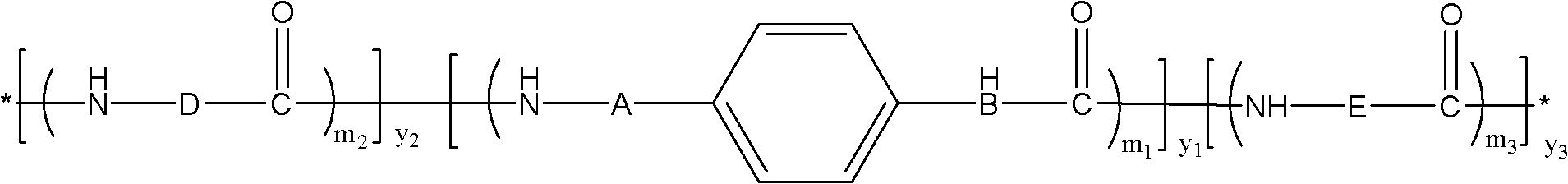

Embodiment 1

[0019] Raw materials: p-phenylenediamine, terephthalic acid, caprolactam, deionized water

[0020] a. Preparation of poly-p-phenylene terephthalamide prepolymer:

[0021] Add p-phenylenediamine and terephthalic acid with a molar percentage of 1:1, and deionized water of 0.5 to 5 times the total mass of the raw materials together into the high-pressure polymerization kettle, pass nitrogen to remove the air, and heat to 200~250℃, keep the pressure at 1~2MPa, keep it for 1~4h, vacuumize for 1~2h, and discharge under nitrogen protection to obtain poly-p-phenylene terephthalamide prepolymer;

[0022] b. Preparation of PA6 prepolymer:

[0023] Add caprolactam and 0.5 to 5 times the mass of deionized water together into the high-pressure polymerization kettle, blow nitrogen to remove the air, heat to 150-200°C, keep the pressure at 1-2MPa, keep it for 1-4h, and vacuum for 1 ~2h, discharge under nitrogen protection to obtain PA6 prepolymer;

[0024] Add 800g (mass ratio 5:5) and 16...

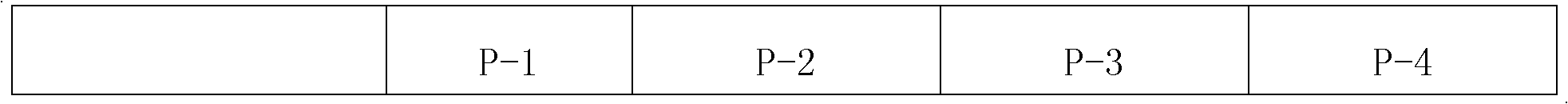

Embodiment 2

[0027] Prepare two kinds of prepolymers according to the step of implementation example 1, by the removal of 1200g poly-p-phenylene terephthalamide prepolymer and 800gPA6 prepolymer (mass ratio 6: 4) and 0.5 times of prepolymer gross mass Add ionized water into the autoclave, seal it, heat it to 220°C, keep the pressure at 1.4MPa, then continue to heat up to 280°C, control the pressure at 2.5MPa, keep it for 4h, vacuumize it for 1h, discharge under nitrogen protection, and get the final product , denoted as P-2.

Embodiment 3

[0029] Prepare two kinds of prepolymers according to the step of embodiment example 1, by the removal of 2100g poly-p-phenylene terephthalamide prepolymer and 900gPA6 prepolymer (mass ratio 7: 3) and 0.5 times of prepolymer gross mass Add ionized water into the autoclave, seal it, heat it to 220°C, keep the pressure at 1.4MPa, then continue to heat up to 280°C, control the pressure at 2.5MPa, keep it for 4h, vacuumize it for 1h, discharge under nitrogen protection, and get the final product , recorded as P-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com