Ultraviolet-curable white character jet-ink and preparation method thereof

An ultraviolet light and white technology, which is applied in the chemical industry, can solve the problems of titanium dioxide, such as large specificity, poor dispersion, and high viscosity, and achieve the effects of scientific components, efficient preparation methods, and excellent comprehensive indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

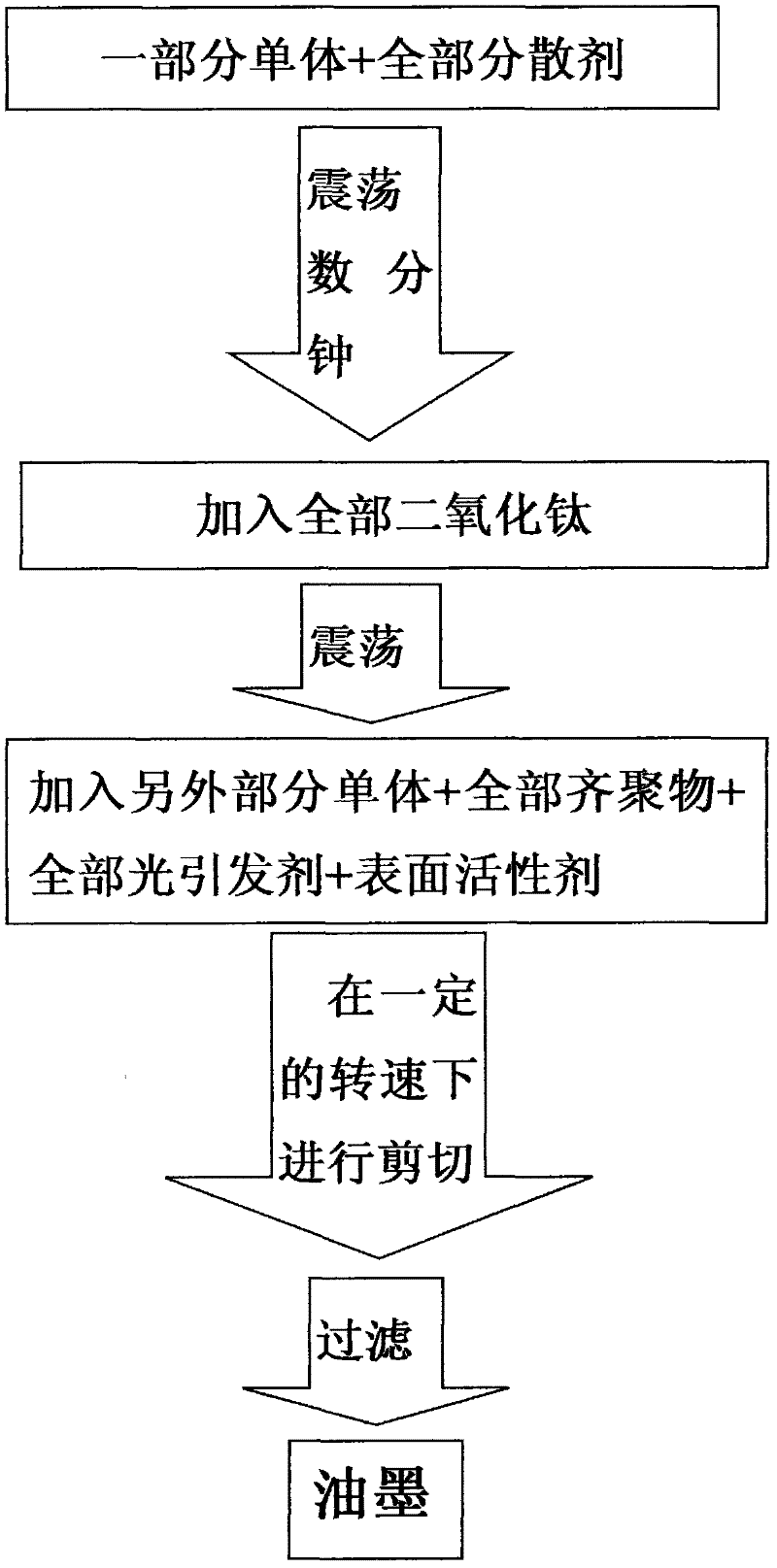

Method used

Image

Examples

Embodiment 1

[0044] A UV-curable white character inkjet, which is made of the following components by weight percentage:

[0045]

[0046]

[0047] Wherein, the oligomer is one of epoxy acrylate, polyester acrylate, polyether acrylate and polyurethane acrylate;

[0048] The reactive monomer is a mixture of monofunctional monomers, bifunctional monomers, trifunctional monomers or multifunctional monomers;

[0049] The titanium dioxide is surface-modified rutile titanium dioxide with a particle size of 100 nm to 500 nm, or one selected from silica, aluminum oxide, and zirconia with a particle size of 150 to 300 nm, coated and modified with organic matter.

[0050] The photoinitiator is selected from one of radical polymerization photoinitiators or cationic polymerization photoinitiators;

[0051] The dispersant is a wetting and dispersing agent for solvent-based systems;

[0052] The surface active agent is selected from one of fluorine surface active agents or organic silicon surface active agents.

[...

Embodiment 2

[0075] Embodiment 2: The UV-curable white character inkjet provided in this embodiment and the preparation method thereof, the basic components and steps are the same as those of Embodiment 1, and the difference lies in:

[0076]

[0077] Among them, the components are specifically selected from titanium dioxide, polyester acrylate, dispersant ANFCNA-4046, surfactant FC4430, white carbon black, and photoinitiator selected from free radical polymerization photoinitiators. The active monomers are as follows in weight percentage Mixture of monomers:

[0078]

[0079] The specific preparation method includes the following steps: (1) Preliminarily put the corresponding formula amount of dispersant and the corresponding formula amount of active monomer into the shaker, shake for 10 minutes to prepare a solution; (2) Add the corresponding formula amount to the solution The titanium dioxide is dispersed in a shaker for 30-60 minutes; (3) Transfer the above mixture to the grinder, start the...

Embodiment 3

[0080] Embodiment 3: The UV-cured white character inkjet provided in this embodiment and its preparation method have the same basic components and steps as Embodiments 1 and 2, and the difference lies in:

[0081]

[0082] The specific components are: titanium dioxide, polyester acrylate, epoxy acrylate, active monomer, cationic polymerization photoinitiator, dispersant ANFCNA-4046, surfactant DC-57, white carbon black. Among them, the titanium dioxide has a surface-modified rutile titanium dioxide with a particle size of 100 nm to 500 nm.

[0083] The reactive monomer is a mixture of the following monomers in weight percentage:

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com