Carrot-containing yogurt and method for producing same

A carrot and yogurt technology, applied in the direction of milk preparations, dairy products, applications, etc., to achieve the effect of good color, reasonable nutrition, and sweet and sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

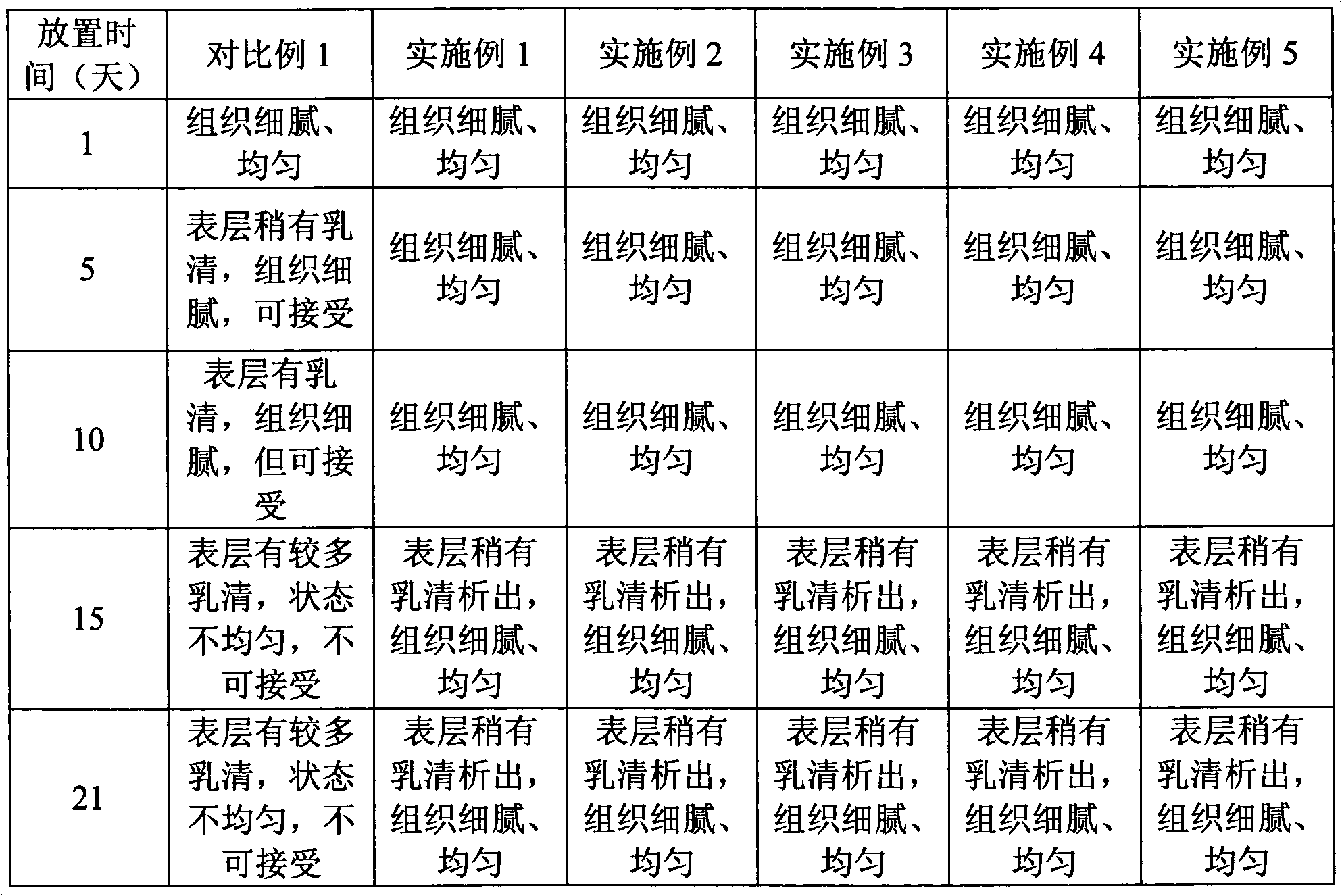

Embodiment 1

[0044] Raw material formula: raw milk 70% (low fat 1.5%); white granulated sugar 9%; pectin 0.2%; modified starch 0.5%; gelatin 0.3%; carrot 20%; ×10 6 cfu / mL, Lactobacillus delbrueckii subsp.bulgaricus 2×10 6 cfu / mL, Lactobacillus plantarum (lactobacillus plantarum) 1×10 6 cfu / mL).

[0045] Preparation of carrot material A: Wash the fresh carrots, stir and cut them into a slurry with a particle size of 6 cfu / mL, Lactobacillus delbrueckii subsp.bulgaricus 1×10 6 cfu / mL, Lactobacillus plantarum (lactobacillus plantarum) 1×10 6 cfu / mL fermentation, when the titrated acidity value of the fermented liquid reaches 70 ° T, stop the fermentation, observe that the carrot has normal color, smell and taste after the fermentation, and has a special fermented flavor, without the vegetable flavor of carrot.

[0046] The preparation method of the yogurt base material: mix each ingredient and fresh milk at 45°C and stir evenly, stir at a speed of 900 rpm for 20 minutes, carry out seconda...

Embodiment 2

[0049] Raw material formula: raw milk 90% (full fat); white granulated sugar 3.5%; pectin 0.3%; modified starch 0.8%; sodium alginate 0.4%; carrot 5%; 10 6 cfu / mL, Lactobacillus casei (Lactobacillus.casei) 1×10 6 cfu / mL, Lactococcus lactis subsp.Lactis 1×10 6 cfu / mL, Lactococcus lactis subsp.Cremoris 1×10 6 cfu / mL).

[0050] Preparation of carrot material A: Wash the fresh carrots, stir and cut them into a slurry with a particle size of 6 cfu / mL, Lactobacillus casei (Lactobacillus.casei) 1×10 6 cfu / mL, fermented at 42°C. When the titrated acidity of the fermented liquid reaches 90°T, stop the fermentation. Observe that the carrot has normal color, smell and taste after fermentation, and has a special fermented flavor without the vegetable flavor of carrot.

[0051] The preparation method of the yogurt base material: Mix and stir each ingredient and fresh milk at 50°C evenly, stir at a speed of 1600 rpm for 15 minutes, carry out secondary homogenization at 55°C and 17MPa; s...

Embodiment 3

[0054] Raw material formula: raw milk 74.8%; white sugar 15%; guar gum 0.15%; pectin 0.05%; carrot 10%; lactic acid bacteria starter: Lactobacillus.acidophilus 1×10 6 cfu / mL, Lactobacillus bulgaricus 1×10 6 cfu / mL, Lactobacillus casei (Lactobacillus.casei) 1×10 6 cfu / mL, Bifidobacterium (Bifidobacterium) 1 × 10 6 cfu / mL, Streptococcus thermophilus (Streptococcus thermophilus) 1 × 10 6 cfu / mL.

[0055] Preparation of carrot material A: Wash the fresh carrots, stir and cut them into a slurry with a particle size of 6 cfu / mL, Lactobacillus casei (Lactobacillus.casei) 1×10 6 cfu / mL, Lactobacillus bulgaricus 1×10 6 cfu / mL, fermented at 42°C. When the titrated acidity value of the fermented liquid reaches 70°T, stop the fermentation. Observe that the carrot has normal color, smell and taste after fermentation, and has a special fermented flavor without the vegetable flavor of carrot.

[0056] The preparation method of the yogurt base material: mix and stir each ingredient and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com