Hot-melt extruded quick release preparation of nimesulide and hot-melt extruding method thereof

A hot-melt extrusion and immediate-release preparation technology, which is applied to non-active ingredients in medical preparations, antipyretics, anti-inflammatory agents, etc. to achieve uniform dispersion, low energy consumption, and no solvent residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

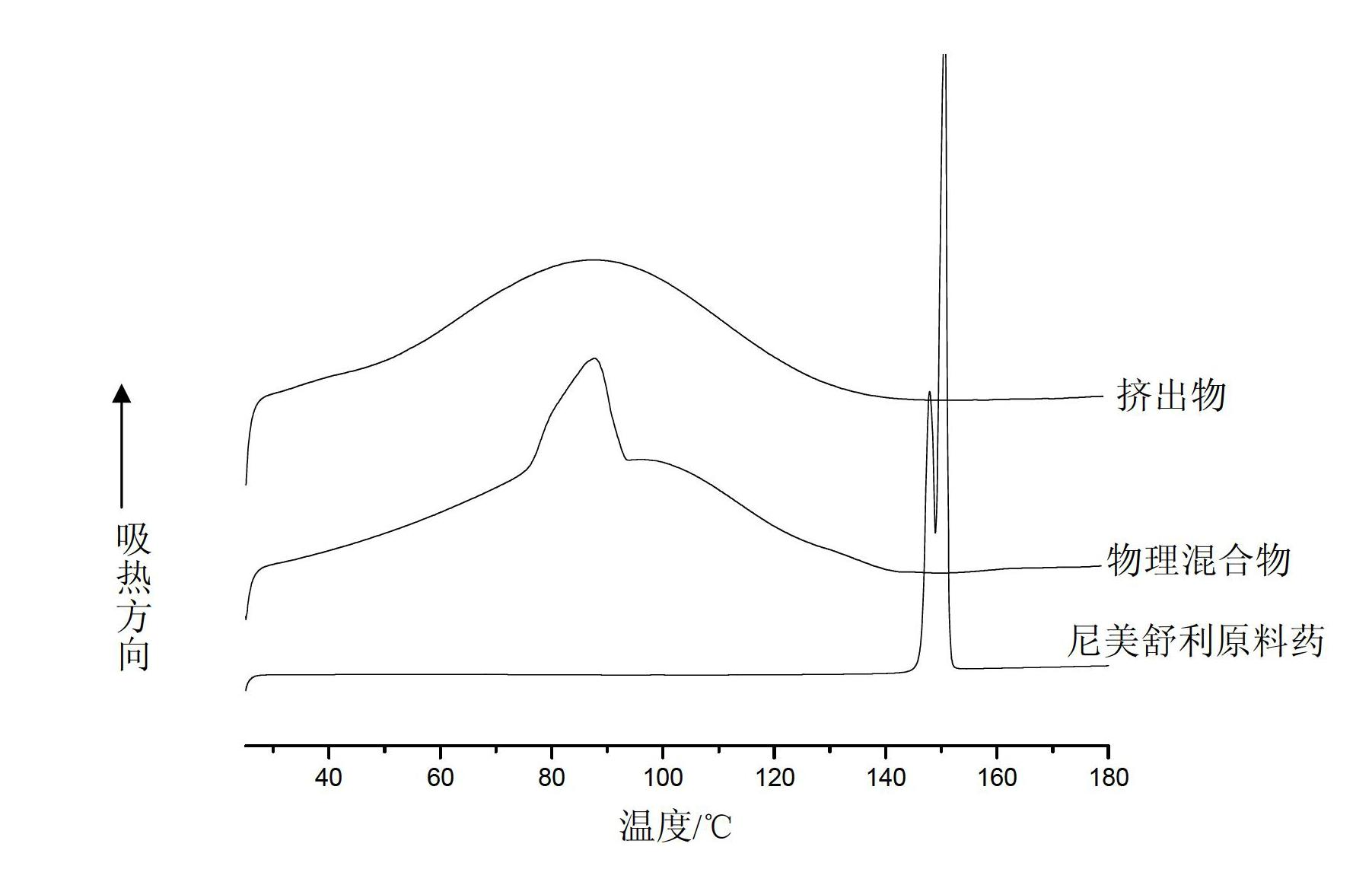

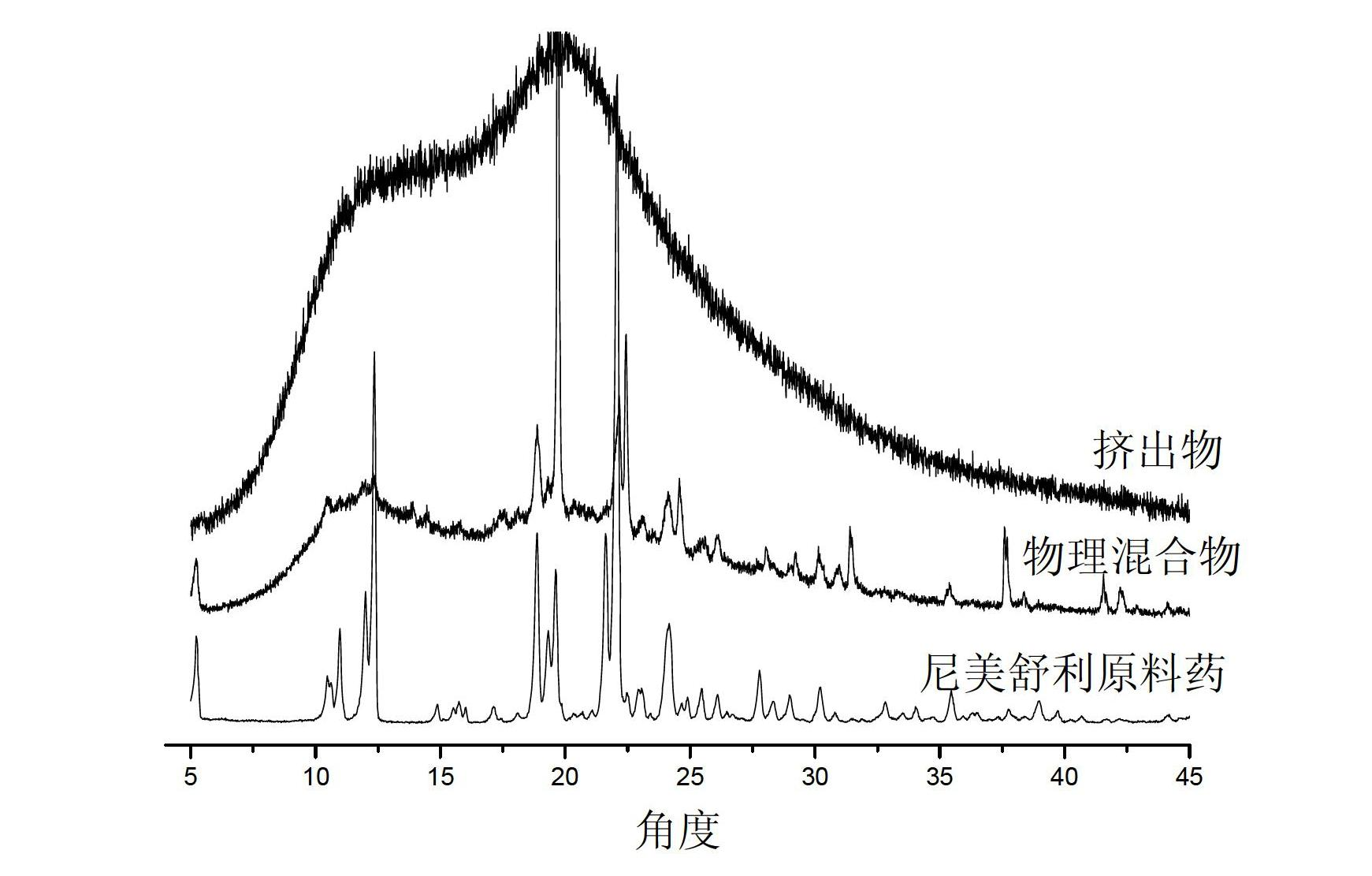

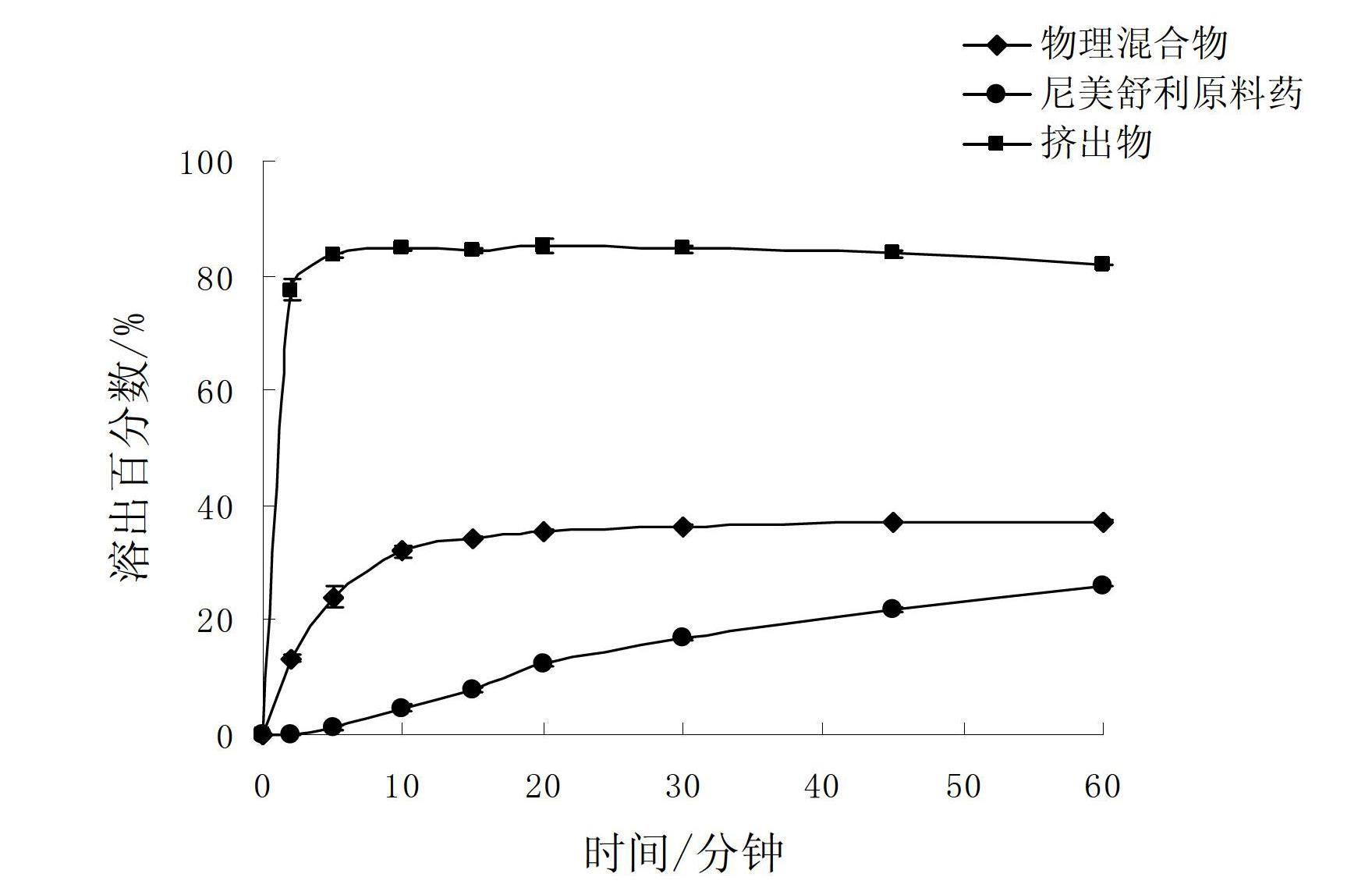

Embodiment 1

[0031] Mix nimesulide (10%), xylitol (10%), and PVPK30 (80%) evenly to prepare a physical mixture. Set the temperature of the extruder at 145°C. After the temperature rises to the set value and stabilizes, Add the physical mixture at a uniform speed to obtain strip-shaped extrudates, cool, pulverize and pass through a 40-mesh sieve to obtain nimesulide solid dispersion particles. The results of the in vitro dissolution test showed that the dissolution rate was 77% in 2 minutes and 84% in 5 minutes; the dissolution rate of the physical mixture was 16% and 29% respectively; the dissolution rate of the raw material was 22% in 45 minutes.

Embodiment 2

[0033] Mix nimesulide (20%), xylitol (5%), and PVPK30 (75%) evenly to prepare a physical mixture. Set the temperature of the extruder at 145°C. After the temperature rises to the set value and stabilizes, Add the physical mixture at a uniform speed to obtain strip-shaped extrudates, cool, pulverize and pass through a 40-mesh sieve to obtain nimesulide solid dispersion particles. According to the in vitro dissolution test results, 74% was dissolved in 2 minutes and 85% in 10 minutes.

Embodiment 3

[0035] Mix nimesulide (10%) and PVP-VA64 (90%) uniformly to prepare a physical mixture, set the temperature of the extruder at 145°C, and when the temperature rises to the set value and stabilizes, add the physical mixture at a uniform speed to obtain Strip-shaped extrudates were cooled and crushed through a 40-mesh sieve to obtain nimesulide solid dispersion particles. According to the in vitro dissolution test results, 67% was dissolved in 2 minutes and 82% in 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com