Method for solidifying sludge of urban sewage treatment factory by using ardealite, coal ash and carbide slag

A technology of urban sewage and fly ash, applied in water/sludge/sewage treatment, sludge treatment, energy wastewater treatment, etc., can solve the problem of low utilization rate of carbide slag, achieve low cost, cost reduction, and increase strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

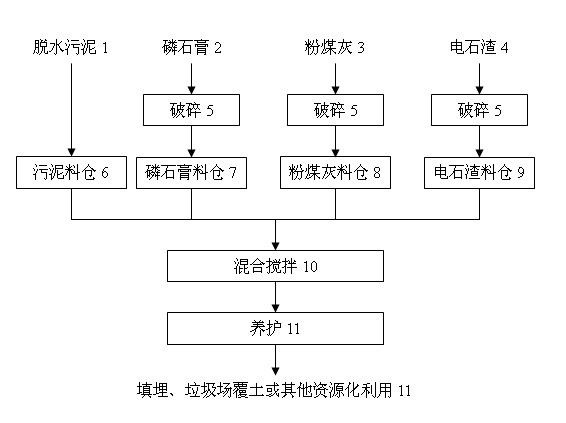

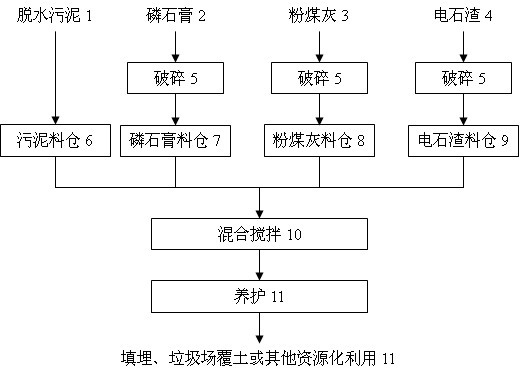

[0026] (1) The sludge from the sewage treatment plant is directly pumped into the sludge silo 1 for temporary storage, and if the phosphogypsum 2, fly ash 3 and carbide slag 4 have been stacked for a long time, hardening and agglomeration will occur. To be crushed 5 first, and then put into the respective feed bins 7, 8, 9;

[0027] (2) Stir and mix the four materials according to the optimal ratio: sludge 70%, phosphogypsum 12%, fly ash 6%, carbide slag 12% (if necessary, it can also be adjusted within the range mentioned above) 10;

[0028] (3) Spread the mixed materials according to the thickness of 20~50cm to the special maintenance area 11 with a canopy for about seven days. The curing time varies greatly with the temperature and seasons in various places. The curing can be completed in about 2 days under the sun in summer in the south, while it may take 2 to 3 weeks in winter in the Central Plains. The solidified sludge after curing can be used as building foundation f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com