Copper wire and method for preparing shielding copper wire mesh

A copper wire and copper mesh technology, applied in online mesh, other household appliances, applications, etc., can solve the problems of in-depth research on the surface treatment technology of copper mesh in the processing and manufacturing process of imported copper mesh, the influence of the quality of processed products, and the impact on the safety of the rotor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

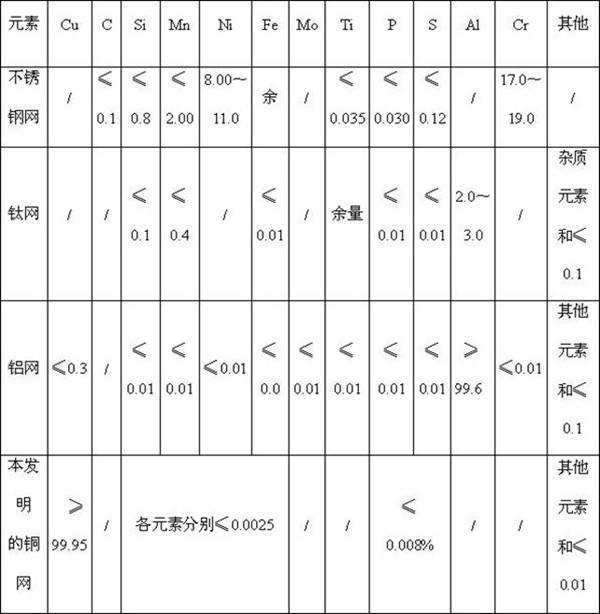

[0046] A copper wire whose chemical composition is calculated by weight percentage: Si≤0.0025%; Mn≤0.0025%; Ni≤0.0025%; O≤0.01%; Bi≤0.005%; P≤0.008%; S≤0.008%; Fe ≤0.0025﹪; As≤0.003﹪, the balance is Cu and other unavoidable impurities.

[0047] The method for preparing shielding copper mesh with above-mentioned copper wire, comprises the following steps:

[0048] a) Weigh each chemical component by weight percentage;

[0049] b), vacuum induction melting;

[0050] Vacuum induction melting adopts primary refining process;

[0051] Refining is carried out at a temperature of 1230±5°C, the vacuum degree is controlled at 3Pa, and the refining is carried out for 10 minutes, followed by electromagnetic stirring and casting into copper ingots.

[0052] c), forged copper billet

[0053] The copper ingot obtained by vacuum melting is forged into a square billet with a side length of 40 mm, and then finished after passing ultrasonic flaw detection and penetration flaw detection; if ...

Embodiment 2

[0075] Copper wire material is with embodiment 1;

[0076] The method for preparing shielding copper mesh with above-mentioned copper wire, comprises the following steps:

[0077] a) Weigh each chemical component by weight percentage;

[0078] b), vacuum induction melting;

[0079] Vacuum induction melting adopts primary refining process;

[0080] Refining is carried out at a temperature of 1260±5°C, the vacuum degree is controlled at 8Pa, the refining is carried out for 20 minutes, and then electromagnetic stirring is carried out to cast copper ingots.

[0081] c), forged copper billet

[0082] The copper ingot obtained by vacuum melting is forged into a square billet with a side length of 80mm in cross-section, and after ultrasonic flaw detection and penetration flaw detection, finishing is carried out; if the billet cross-section is too small, hot rolling is inconvenient;

[0083] d), processing round bars

[0084] The finished copper billet is hot-rolled into a φ14mm ...

Embodiment 3

[0104] Copper wire material is with embodiment 1;

[0105] The method for preparing shielding copper mesh with above-mentioned copper wire, comprises the following steps:

[0106] a) Weigh each chemical component by weight percentage;

[0107] b), vacuum induction melting;

[0108] Vacuum induction melting adopts primary refining process;

[0109] Refining is carried out at a temperature of 1245±5°C, the vacuum degree is controlled at 5 Pa, and the refining is carried out for 15 minutes, followed by electromagnetic stirring and casting into copper ingots.

[0110] c), forged copper billet

[0111] The copper ingot obtained by vacuum melting is forged into a square billet with a side length of 60 mm, and then finished after passing ultrasonic flaw detection and penetration flaw detection; if the billet cross section is too small, hot rolling is inconvenient;

[0112] d), processing round bar

[0113] Hot-roll the finished copper billet into a 10mm round bar at a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com