Zero point energy automobile ultralow emission device

A technology for emitters and automobiles, which is applied in exhaust devices, machines/engines, air quality improvement, etc. It can solve the problems of easy saturation, decomposition and elimination, and increase in use costs, so as to eliminate harmful substances and eliminate exhaust emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

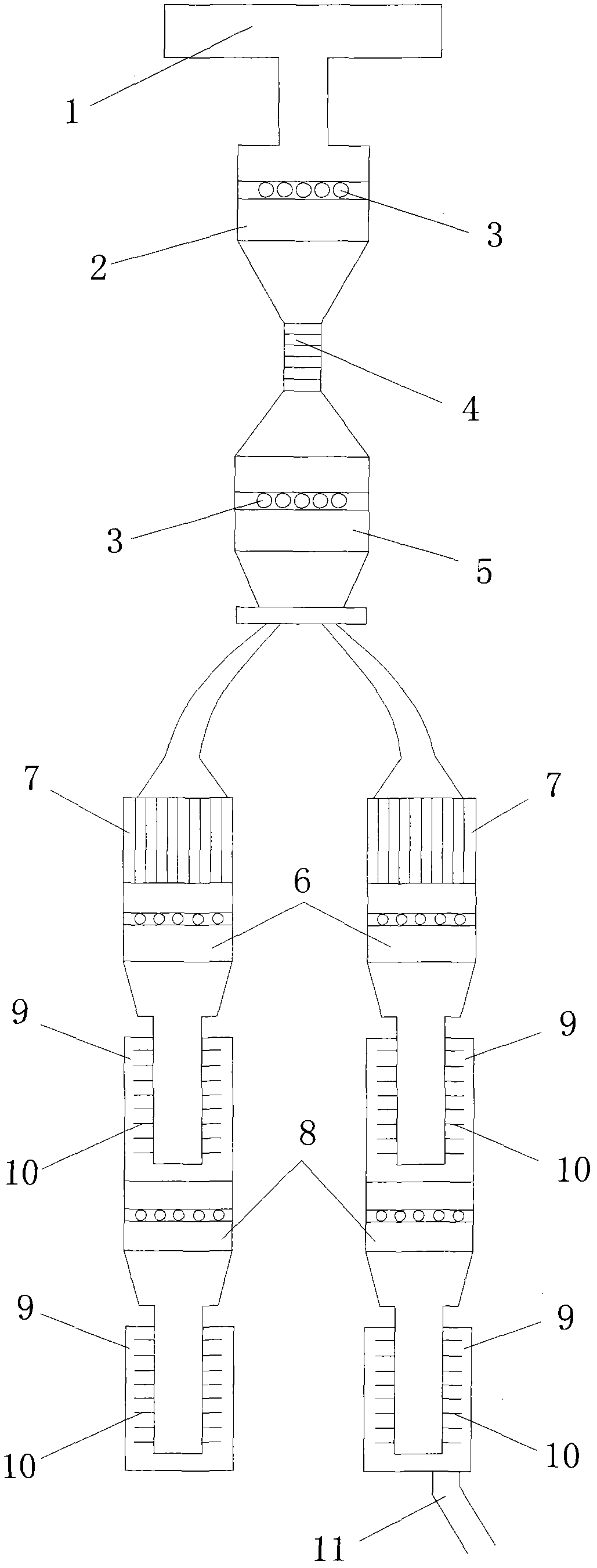

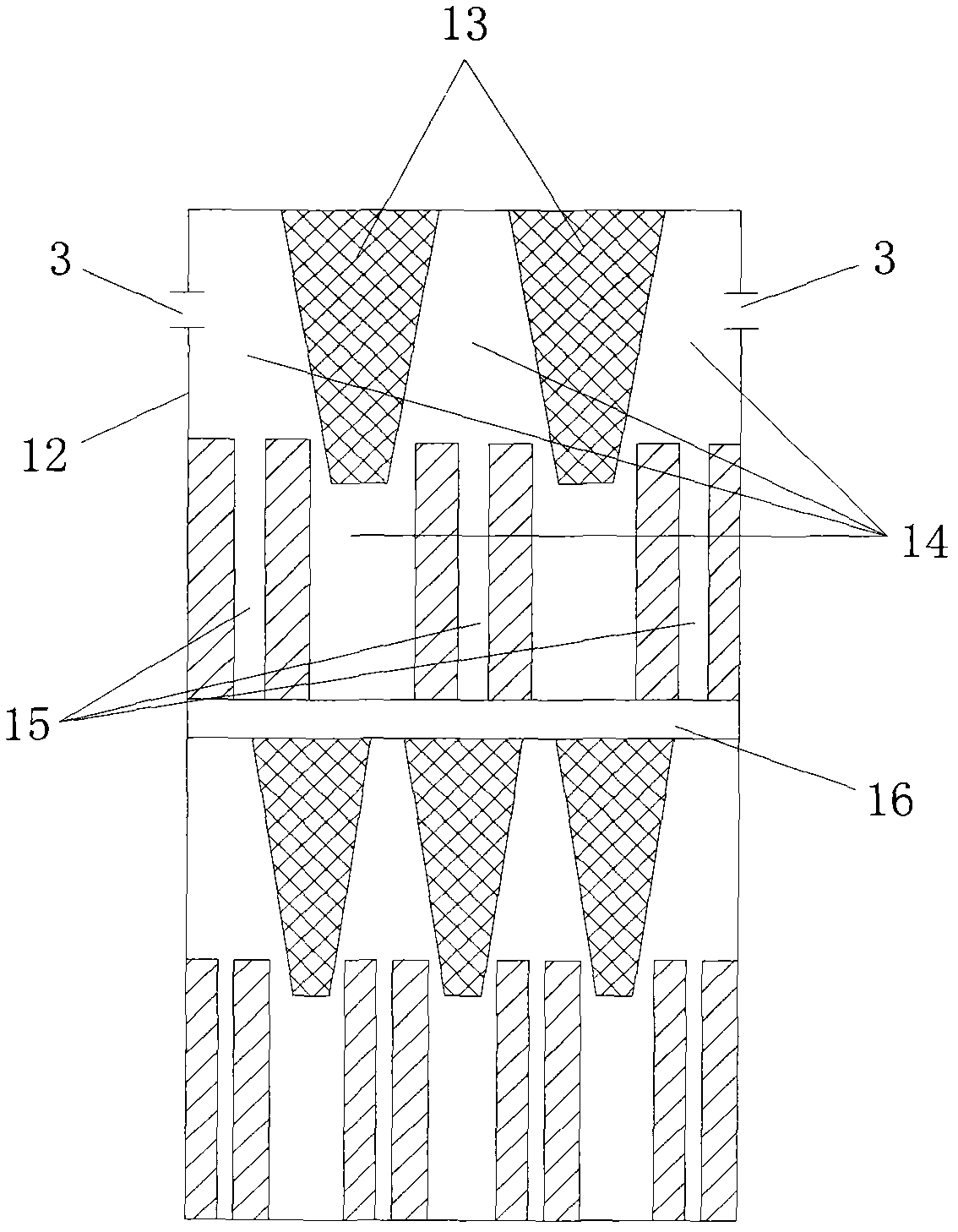

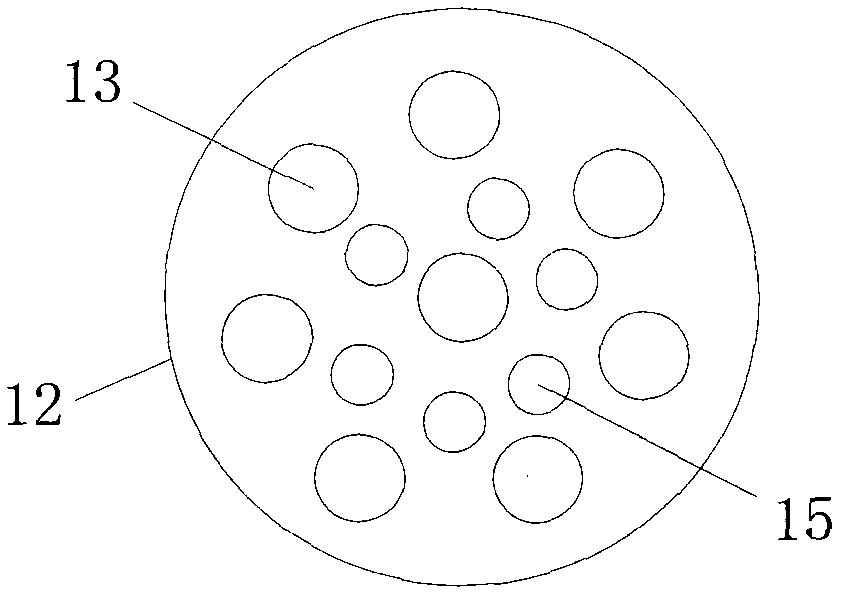

[0014] In this embodiment, the four-stage exhaust gas purification treatment system used for small cars is taken as an example for further description. figure 1 , figure 2 with image 3 , the vacuum energy automobile ultra-low emission device, which is connected with the automobile combustion chamber 1, includes an air converter, a radiator and a noise elimination and gas elimination device; the main road includes a first-stage 2 and a second-stage 5 air converter, the first Stage 2 is connected to the second stage 5 air converter through the corrugated connecting pipe 4, wherein the input end of the first stage 2 air converter is connected to the automobile combustion chamber 1, and the output end of the second stage 5 air converter outputs two branches; each One branch includes a radiator 7, the front end of the radiator 7 is connected to the second-stage 5 air converter of the main road, the rear ends of the two radiators 7 are respectively connected to a third-stage 6 ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com