A kind of preparation method of lithium-ion battery cathode material with high conductivity

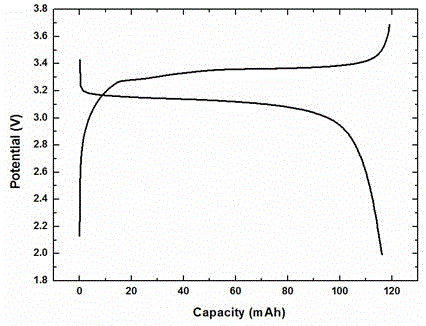

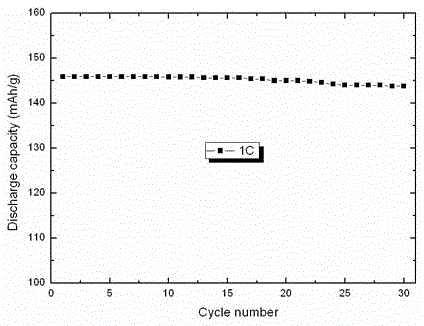

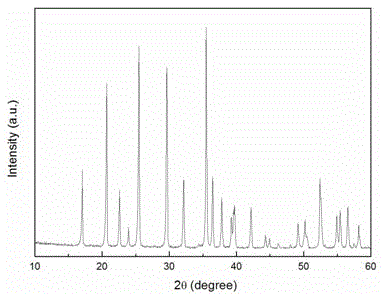

A technology of lithium ion battery and positive electrode material, applied in battery electrodes, circuits, electrical components, etc., to achieve excellent cycle performance, uniform distribution, and good rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve lithium dihydrogen phosphate and iron nitrate in an appropriate amount of deionized water at a molar ratio of Li:Fe=1:1 to prepare a solution with a concentration of 3mol / L; drop silver nitrate solution with a concentration of 5% into the concentration In a 20% ammonia solution, a silver ammonia solution is formed; the above 3mol / L solution is slowly dropped into the silver ammonia solution according to the ratio of Fe:Ag=20:1, and then the pH value of the solution is adjusted to 9.5 by ammonia water; Glucose solution with a concentration of 30% is slowly dripped into the above solution with a pH value of 9.5, and the molar ratio of glucose to silver is controlled to be 1:1, and then at 80 o Magnetic stirring was carried out under C to form the precursor; after the precursor was simply ground, it was put into a tube furnace protected by argon for sintering, and the sintering temperature was 300 o C, the sintering time is 4 hours, and the pretreatment powder is ...

Embodiment 2

[0026] Dissolve lithium dihydrogen phosphate and iron acetate in a molar ratio Li:Fe=1:1 in an appropriate amount of deionized water to prepare a solution with a concentration of 3.5mol / L; drop a 4% silver nitrate solution into the In the ammonia solution with a concentration of 15%, a silver-ammonia solution is formed; the above 3.5mol / L solution is slowly dropped into the silver-ammonia solution according to the ratio of Fe:Ag=50:1, and then the pH value of the solution is adjusted to 9 by ammonia water ; Slowly drip the glucose solution with a concentration of 35% into the above solution with a pH value of 9, and control the molar ratio of glucose to silver to be 1.2:1, then at 85 o C under magnetic stirring to form a precursor; after grinding the precursor, put it into a tube furnace with argon protection for sintering, the sintering temperature is 350 o C, the sintering time is 3 hours, and the pretreatment powder is obtained; the pretreatment powder is then sintered in a...

Embodiment 3

[0028] Dissolve lithium dihydrogen phosphate and ferric nitrate in deionized water at a molar ratio of Li:Fe=1:1 to prepare a solution with a concentration of 6mol / L; drop silver nitrate solution with a concentration of 4.5% into the solution with a concentration of 35 % ammonia solution to form a silver ammonia solution; the above 4.5mol / L solution is dripped into the silver ammonia solution according to the ratio of Fe:Ag=76:1, and then the pH value of the solution is adjusted to 9.7 by ammonia water; the concentration is 21.5% glucose solution is slowly dripped into the above solution with a pH value of 9.7, and the molar ratio of glucose to silver is controlled to be 1.5:1, and then at 90 o Stirring at C to form a precursor; after grinding the precursor, put it into a tube furnace filled with argon and nitrogen (volume ratio 1:1) gas mixture for sintering, the sintering temperature is 320 o C, the sintering time is 4 hours, and the pretreatment powder is obtained; the pret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com