Integrated cartridge

A technology of cartridge and filter material, applied in the field of analyzing biomolecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

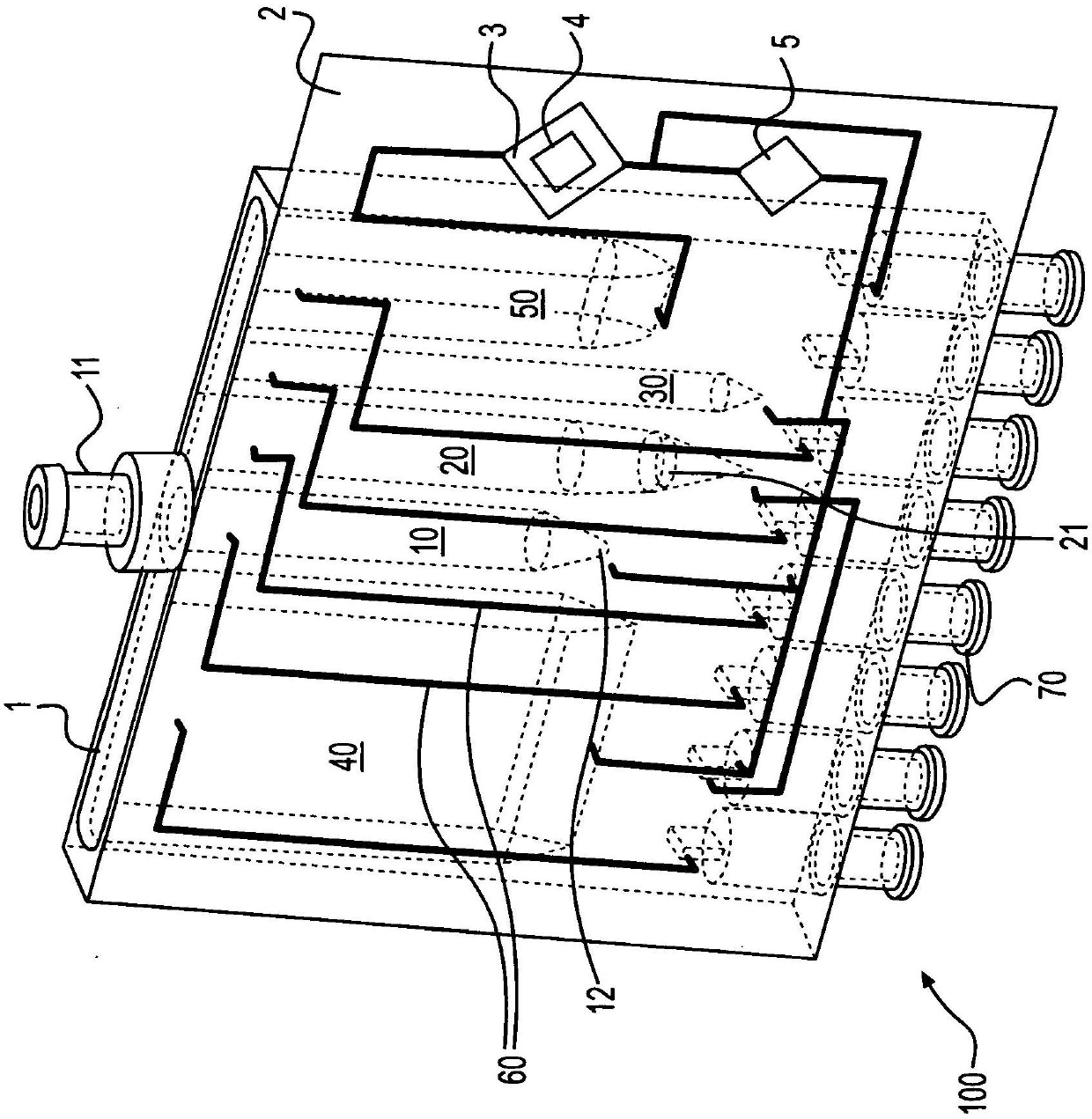

[0099] Example 1: Components of a Microarray-Based Sample Analysis (MBSA) System

[0100] A. Fluid Subsystem

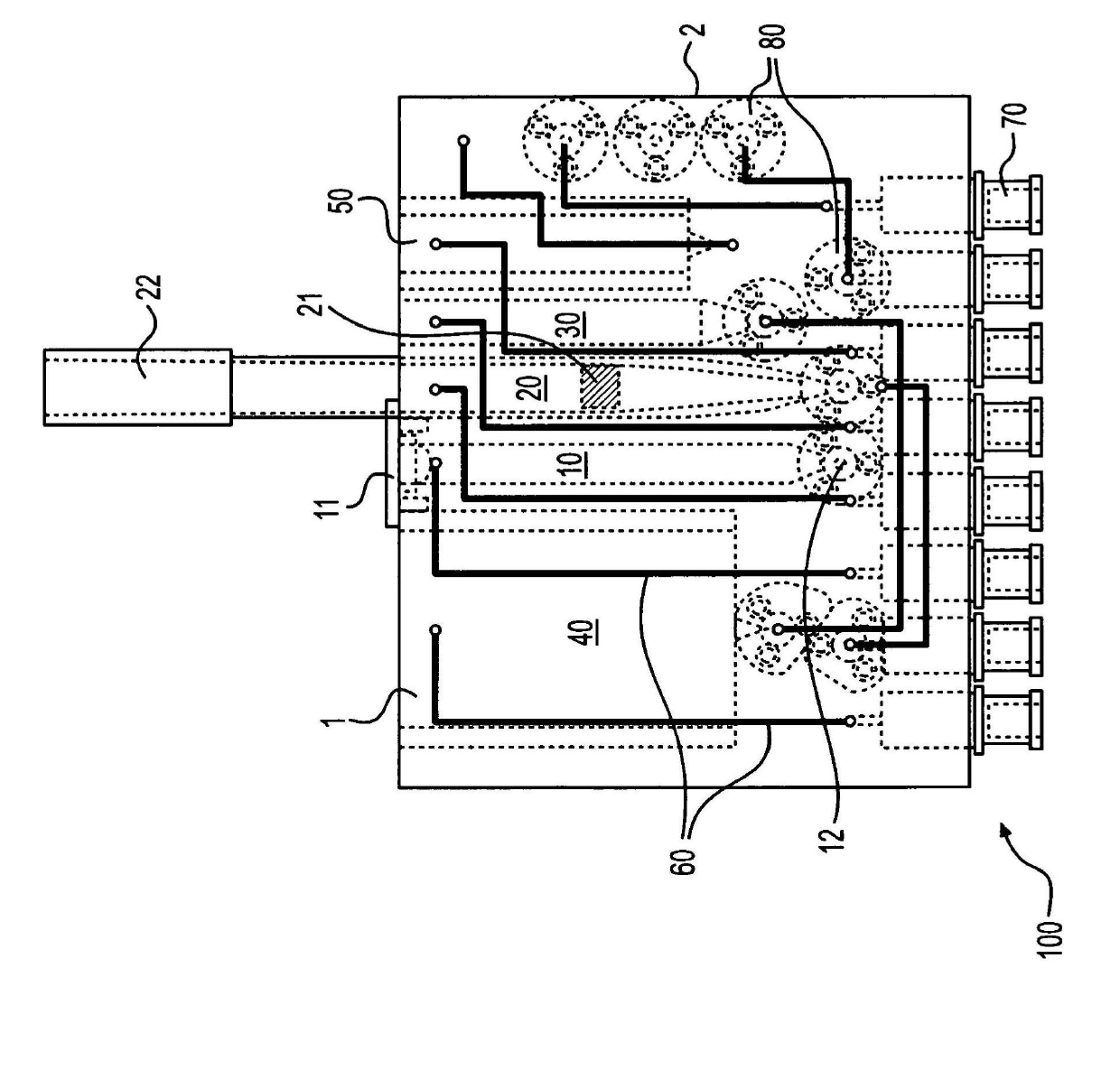

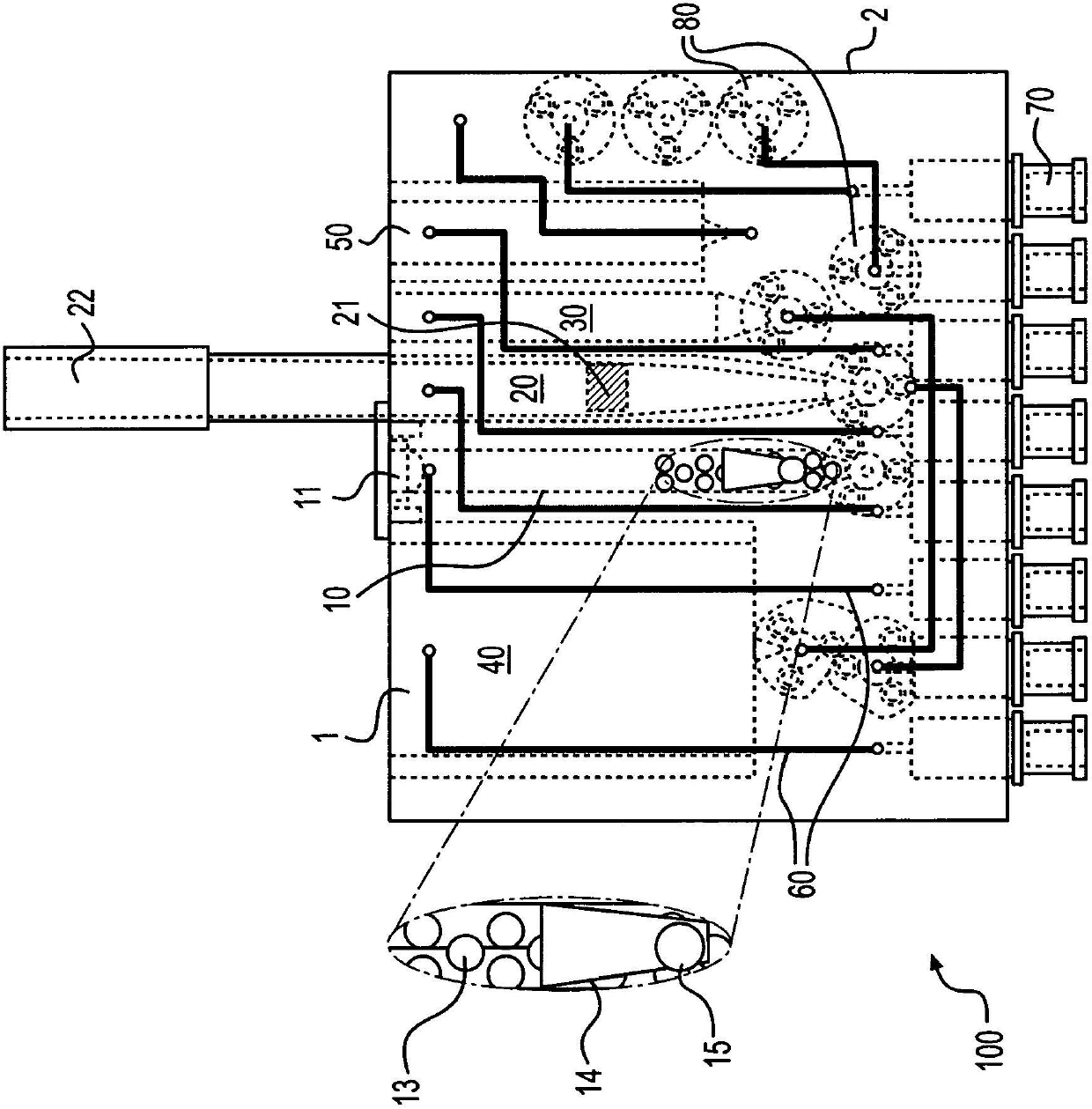

[0101] The fluidic subsystem consists of three types of functional components: a bidirectional microfluidic pump, a selector valve, and a cartridge "needle" valve. Figure 5 is a schematic diagram showing the fluid subsystem of the pump and selector valve connected to the integrated cartridge. The fluid layout uses a combination of bi-directional pumps and selector valves available from Global FIA. Such as Figure 5 As shown, the fluidic subsystem is connected to the integrated cartridge by a fluid manifold 90 and holds various reagents in storage containers external to the integrated cartridge 100 .

[0102] Figure 6A One embodiment of fluid manifold 90 is shown. In this embodiment, the manifold 90 allows two fluidic fittings 91 to be connected to each cartridge port 72 . The manifold has eight bosses 94 with Luer tips. These sleeves have fluid channels that ...

Embodiment 2

[0130] Example 2: Using an integrated cartridge and a microarray-based sample analysis system to detect bacteria in a test sample.

[0131] The sequence of events for the MBSA system is as follows. A user introduces a sample into the integrated cartridge. The system then performs the following automated steps: Prepare the sample, use the BladderThermocycler TM Perform PCR, mix the PCR product with hybridization and / or APEX reaction mixture, transfer the mixture to the microarray chamber, perform hybridization with the microarray, and then detect the microarray image.

[0132] In one embodiment, the sequence of sample preparation on the cartridge is: introduce sample into sample column, introduce binding buffer into sample column, mix with air, transport sample mixture to TruTip column, switch between columns, dispense to Waste, introduce wash buffer into TruTip columns, switch between columns, distribute to waste, introduce elution buffer, then distribute to elution columns....

Embodiment 3

[0142] Example 3: Genotyping of single nucleotide polymorphisms (SNP typing) using an integrated cartridge and a microarray-based sample analysis system

[0143] This example shows the feasibility of a microfluidic controlled system for SNP typing of physical markers that can be used in forensic applications. The experimental setup combined components for sample preparation, PCR amplification, and allele-specific primer extension microarray (AS-APEX) to form an all-in-one system to detect markers for eye color. The system includes fluid handling subsystems (e.g. pumps), thermal cycling subsystems (e.g. Akonni Bladder Thermocycler), optical instruments (e.g. Akonni Reader), disposable integrated cartridges (i.e. Akonni TruTip, Akonni PCR / TruArray flow cell , microfluidic pathways and microfluidic valves) and a cartridge docking station.

[0144] The 6 SNPs listed in Table 1 were used as test models for the experiments. These SNPs have been reported in the literature as major ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com