Simulated moving bed for chromatography device

A technology of simulated moving bed and chromatographic chromatography, which is applied in the field of material separation, can solve the problems that the filler and the fluid cannot move relative to each other, and cannot be used as a simulated moving bed, so as to achieve the effect of improved separation efficiency and simple expansion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

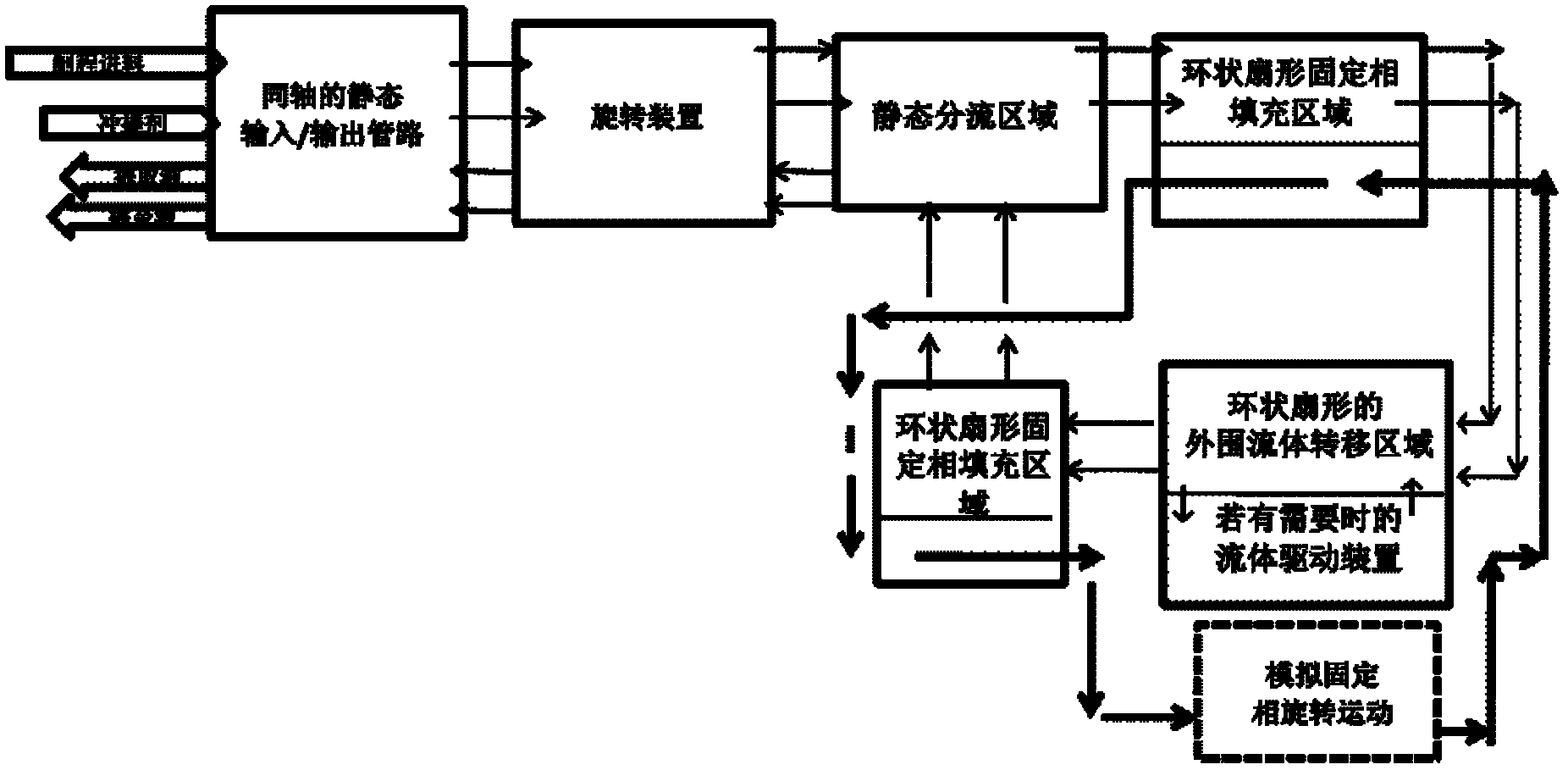

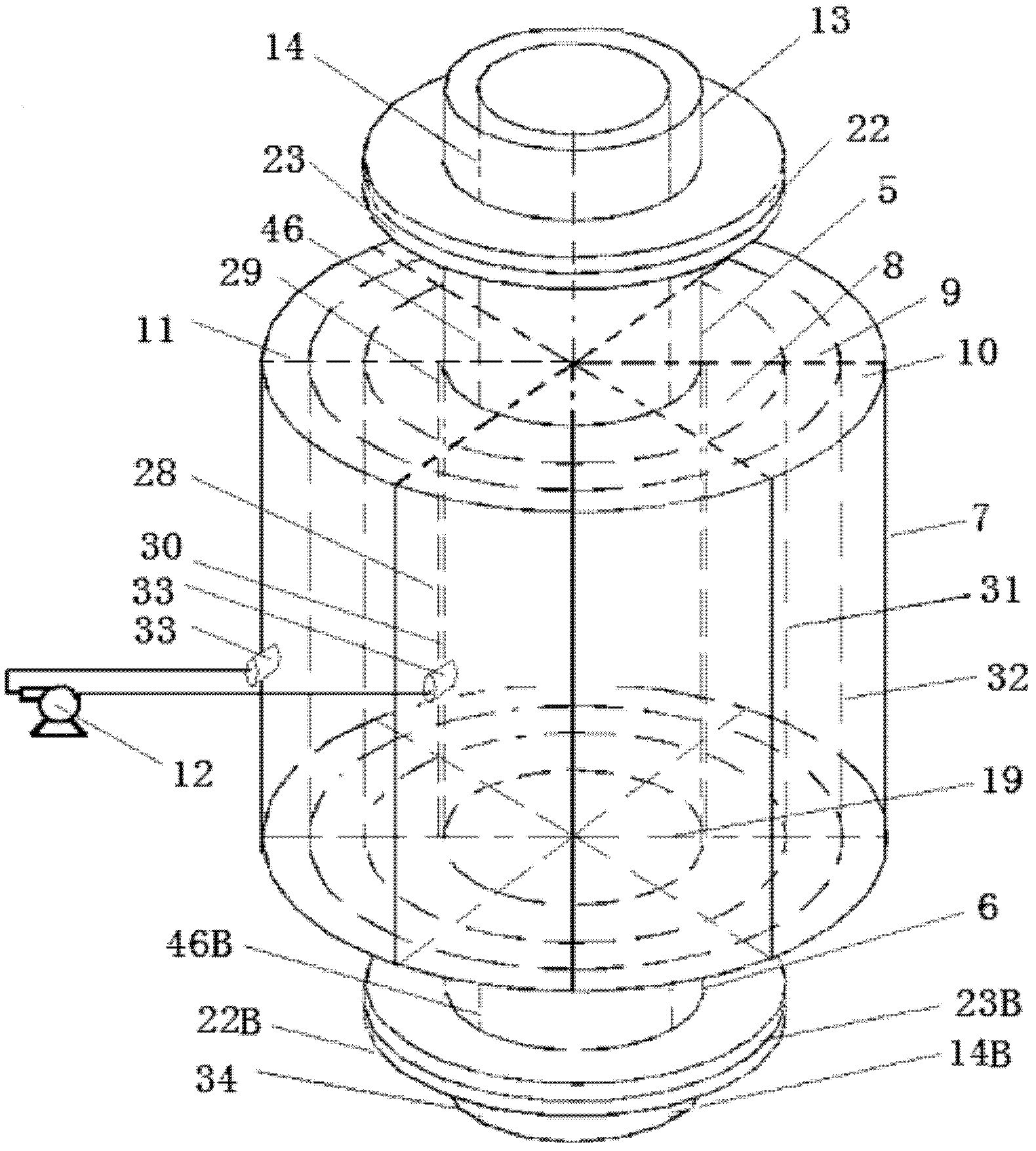

[0059] Such as figure 1 As shown, in the simulated moving bed chromatography device in this embodiment, there is fluid radial flow in each stationary phase packed bed.

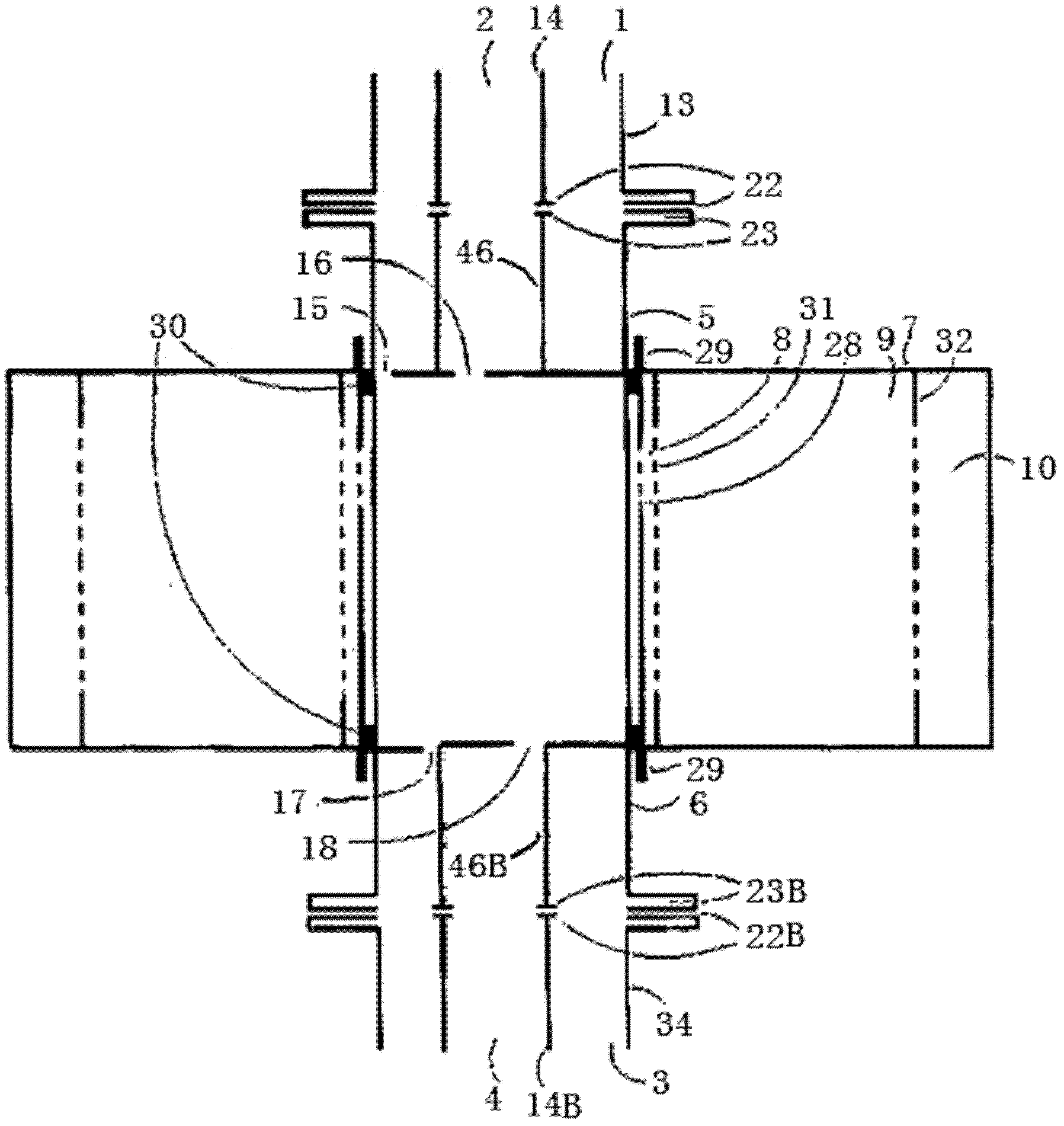

[0060] Such as figure 2 As shown, it is a side view of the simulated moving bed chromatography device with two static pipelines in this embodiment.

[0061] Such as figure 1 , figure 2 and image 3 As shown, this embodiment includes: a static pipeline with several input / output channels 1, 2, 3, 4;

[0062] A rotary device connected to the static pipeline, the rotary device includes: a plurality of rotary fluid channels for receiving or delivering fluid from the input and output channels respectively.

[0063] The static partition container 7 connected with the rotating device, the static partition container 7 includes: a static split area 8, a stationary phase filling area 9 and a peripheral fluid transfer area 10, between the units of each static split area 8, each The units in the stationary phase fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com