Composite mould for manufacturing casting fireproof materials

A technology of melting and casting refractory materials and composite molds, which is applied in the field of melting and casting refractory materials, can solve the problems of easy cracking of products and easy collapse of boxes, and achieve the effects of improving quality, saving energy, and solving easy collapse boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

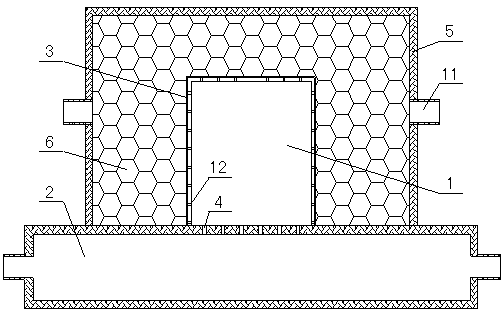

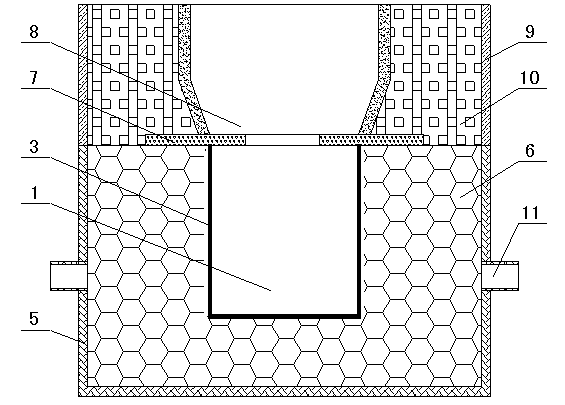

[0020] This example illustrates a composite mold for producing fused-cast zirconium corundum products with a size of 250×400×1200 mm. Refer to attached Figure 1-2 As shown, the composite mold is prepared through the following steps:

[0021] Riser 8 adopts thermal insulation heating element to make template (containing 2.2-3.5 wt% silicon fiber, 72-85wt% quartz sand, 2.5-5.0wt% aluminum powder, 2.5-6.0wt% ferric oxide, 1.2 -2.5 manganese dioxide, 0.8-1.5wt% furan resin and 0.6-1.5wt% phenolic resin), according to the drawing shape set by the process, 400 (high) × 400 × 40mm (thick) (2 pieces) And 400 (height) × 250 × 40 mm (thickness) (2 pieces) thermal insulation and heating body boards, which are fastened and assembled together with steel wires with a diameter of 2mm.

[0022] A hollow negative pressure forming model 1 (dimensions 250×400×1200 mm) will be made according to the shape of the product (a metal model, such as an aluminum or aluminum alloy model), will be conne...

Embodiment 2

[0027] This embodiment exemplarily illustrates the composite mold for producing fused-cast zirconium corundum products 250×400×1200mm, refer to the attached Figure 1-2 As shown, the composite mold is prepared through the following steps:

[0028] Riser 8 adopts resin sand mold riser 8 (furan resin 3wt%, quartz sand 97wt%), according to the drawing shape set by the process, the internal shape of riser 8 made of resin sand mold is 600 (height) × 400 × 250mm, The wall thickness around the riser 8 is 30mm.

[0029] A hollow negative pressure forming model 1 (dimensions 250×400×1200 mm) will be made according to the shape of the product, connected to the vacuum pumping chamber 2, and a softening heating device will be used to soften the EVA film 3 (EVA with a vinyl acetate content of 32wt%) Plastic film) is softened and covered on the outer surface of the model 1, and the air in the special model 1 and between the special film 3 and the special model 1 is removed through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com