Purification method for high-purity quartz with ultra-low metal elements

A technology of metal elements and purification methods, applied in glass forming, silica, glass manufacturing equipment and other directions, can solve the problems of complex process, many fluid inclusions, application limitations, etc., and achieve the effect of simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Material selection

[0039] Choose SiO 2 The content of ≥98.5wt%, the total amount of impurity metal elements is 42ppm, the number of fluid inclusions 2 Veined quartz sand. The vein quartz sand is provided by Jiangsu Kaida Quartz Co., Ltd. The method for determining the number of inclusions: ①make the quartz sand into an optical flake; ②observe the optical flake under a transmission microscope; ③select randomly three 1mm under the flake 2 Count the number of inclusions, and finally take the average value.

[0040] (2) Roasting-water quenching

[0041] The 96-250μm quartz sand obtained by the above classification is calcined in a muffle furnace at 300°C for 1 hour, and then placed in ice water for quenching treatment until the quartz sand and ice water have a constant temperature, precipitate, filter, and dry.

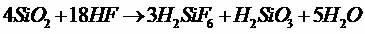

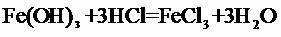

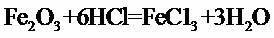

[0042] (3) Chemical purification

[0043] The water-quenched product is reacted in a mixed acid at 60°C for 10 hours, and the mixed acid is HF and HNO 3 , HCl mixed ...

Embodiment 2

[0048] (1) Material selection

[0049] Vein quartz raw ore is sorted, crushed, ground, strong magnetic separation, and classified into vein quartz sand of 96~250μm. The vein quartz sand satisfies the number of fluid inclusions2 , SiO 2 The content of ≥98.5wt%, the total amount of impurity metal elements <100ppm.

[0050] (2) Roasting-water quenching

[0051] The grained quartz sand of 96-250 μm obtained by the above classification is roasted in a muffle furnace at 400° C. for 1 hour, and then placed in ice water for quenching treatment until the quartz sand and ice water have a constant temperature, precipitation, filtration, and drying.

[0052] (3) Chemical purification

[0053] The water-quenched product is reacted in a mixed acid at 30°C for 5 hours, and the mixed acid is HF and HNO 3 , HCl mixed solution, the content of HF in the mixed solution is 3wt%, HNO 3 The content of HCl is 4wt%, and the content of HCl is 30wt%.

[0054] (4) Chelation

[0055] The acid leached product in the ...

Embodiment 3

[0058] (1) Material selection

[0059] Vein quartz raw ore is sorted, crushed, ground, strong magnetic separation, and classified into vein quartz sand of 96~250μm. The vein quartz sand satisfies the number of fluid inclusions2 , SiO 2 The content of ≥98.5wt%, the total amount of impurity metal elements is 42ppm.

[0060] (2) Roasting-water quenching

[0061] The grained quartz sand of 96-250 μm obtained by the above classification is roasted in a muffle furnace at 300° C. for 5 hours, and then placed in ice water for quenching treatment until the quartz sand and ice water have a constant temperature, sedimentation, filtration, and drying.

[0062] (3) Chemical purification

[0063] The water-quenched product is reacted in a mixed acid at 90°C for 8 hours, and the mixed acid is HF and HNO 3 , HCl mixed solution, the content of HF in the mixed solution is 4wt%, HNO 3 The content of HCl is 4wt%, the content of HCl is 30wt%, and the mass ratio of the mixed acid to the water quenched produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com