Method for combining ethylene glycol monoethyl ether with ternary composite metal oxide as catalyst

A ethylene glycol monoethyl ether and ternary compound technology, which is applied in the preparation of ethers and ethers from alkylene oxides, can solve the problems of limited reserves and high prices of rare earth ions, and achieves low by-products, high selectivity and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

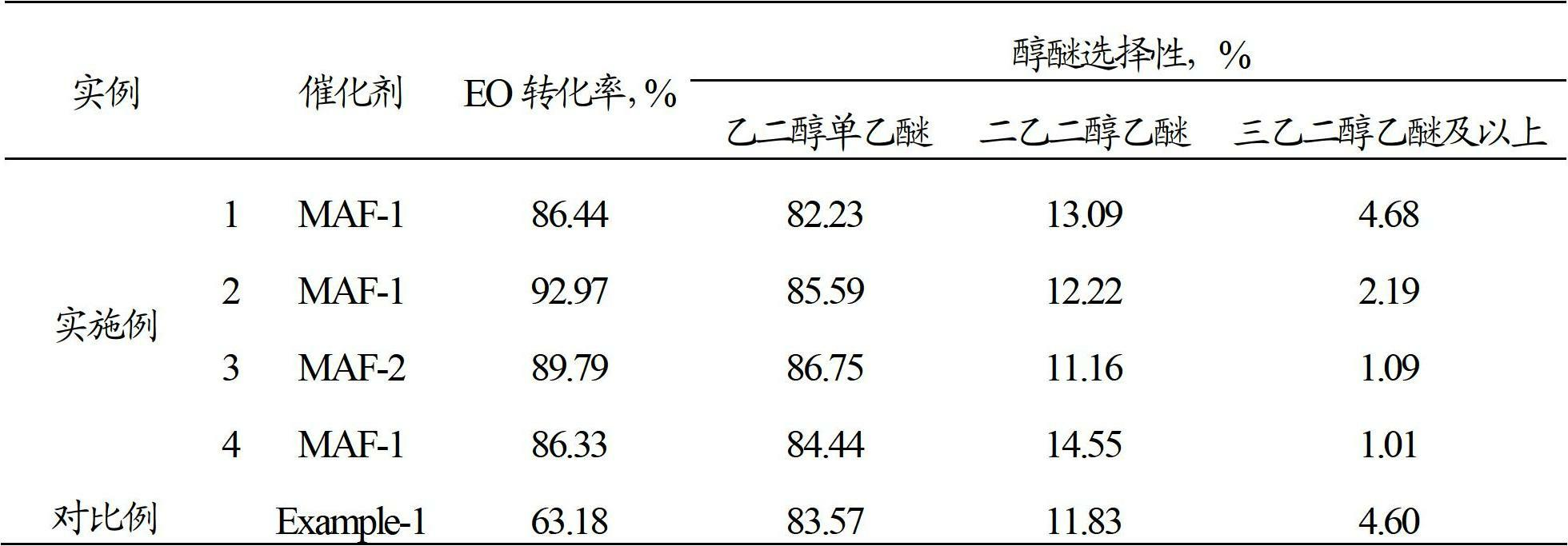

Embodiment 1

[0021] Using co-precipitation method, 18.49g Mg(NO 3 ) 2 ·6H 2 O, 9.02g Al(NO 3 ) 3 9H 2 O, 1.9523gFe(NO 3 ) 3 9H 2 O was dissolved in 100mL deionized water, so that Fe in the solution 3+ / Al 3+ 0.2, stir to dissolve it for later use; configure 2.0mol L -1 100mL of NaOH solution; take a 500mL beaker, configure 100mL 0.5mol L -1 Na 2 CO 3The solution was placed in a water bath at 60°C, and the above-mentioned mixed nitrate solution and NaOH solution were slowly dropped into it under stirring, and the pH of the mixed solution was made to be 10 by controlling the dropping speed of the two. Continue stirring after the dropwise addition, crystallize at 60°C for 6h, filter and wash until neutral, and dry the obtained white solid in an oven at 120°C for 10h to obtain Mg-Al-Fe ternary hydrotalcite. After the above-mentioned Mg-Al-Fe hydrotalcite was calcined at 500°C in air for 8 hours, the obtained block was crushed to 20-40 mesh to obtain the required catalyst, which wa...

Embodiment 2

[0024] Using the catalyst MAF-1 prepared in Example 1, both ends of a 50 cm long reaction tube were filled with quartz sand, the middle of the tube was filled with 2.15 g of MAF-1, and placed in a fixed-bed reaction device. N 2 Purge the reaction tube for 10 minutes, set the pressure to 0.4MPa, and heat the reaction tube to 120°C at the same time. The reaction raw materials ethanol and ethylene oxide were respectively pumped with a flow pump at 6.0mL·h -1 and 2.1mL·h -1 The flow rate is injected into the reactor, and the product enters the receiving tank at the bottom of the device after the first-stage condensation and the second-stage condensation, and the ethylene glycol monoethyl ether product can be obtained.

Embodiment 3

[0026] Using co-precipitation method, 18.49g Mg(NO 3 ) 2 ·6H 2 O, 9.02g Al(NO 3 ) 3 9H 2 O, 9.7615gFe(NO 3 ) 3 9H 2 O was dissolved in 100mL deionized water, so that Fe in the solution 3+ / Al 3+ 1.0, stir to dissolve it for later use; configure 2.0mol L -1 100mL of NaOH solution; take a 500mL beaker, configure 100mL 0.5mol L -1 Na 2 CO 3 The solution was placed in a water bath at 60°C, and the above-mentioned mixed nitrate solution and NaOH solution were slowly dropped into it under stirring, and the pH of the mixed solution was made to be 10 by controlling the dropping speed of the two. Continue stirring after the dropwise addition, crystallize at 60°C for 6h, filter and wash until neutral, and dry the obtained white solid in an oven at 120°C for 10h to obtain Mg-Al-Fe ternary hydrotalcite. After the above-mentioned Mg-Al-Fe hydrotalcite was calcined at 500°C in air for 8 hours, the obtained block was crushed to 20-40 meshes to obtain the required catalyst, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com