Polylactic acid and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) nano modified composite

A -co-4-, hydroxybutyrate technology, applied in the field of new polylactic acid PLA and poly nano-modified composite materials, can solve the problems of poor impact resistance, slow crystallization speed, and low heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

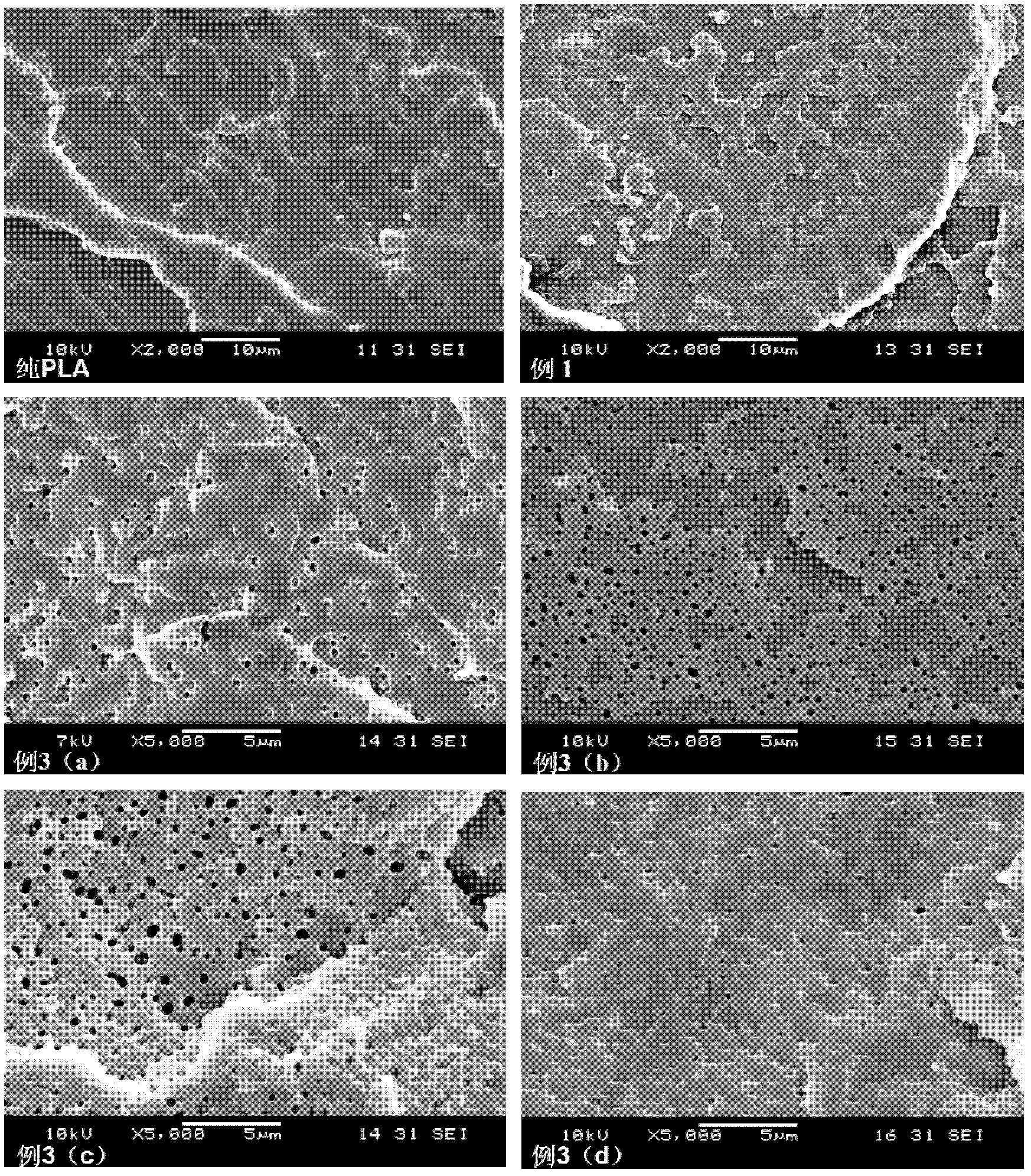

Image

Examples

preparation example Construction

[0023] The preparation steps of modified composite material of the present invention are:

[0024] (1) Add PLA, P3 / 4HB with a certain 4HB content and fillers or additives according to the specified ratio, and add them to a high-speed mixer and stir at high speed for 5-8 minutes to obtain a premixed base material;

[0025] (2) the premixed base material is used to blend and extrude the strip with a twin-screw extruder;

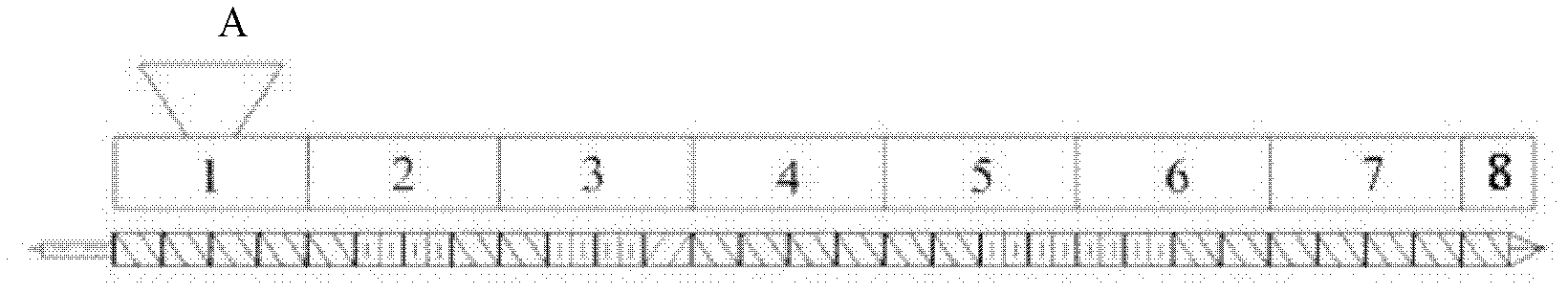

[0026] The screw configuration of the twin-screw extruder is as follows figure 2 shown. Among them, the setting parameters of the twin-screw are: the main engine frequency is 10Hz, the feeding frequency is 8Hz, the setting from the feeding port to the machine head is set to 8 sections, and the temperature setting values of each section of 1, 2, 3, 4, 5, 6, 7, and 8 are respectively 0°C, 150°C, 160°C, 170°C, 180°C, 180°C, 180°C, 180°C; the setting parameters of the barrel temperature of the injection molding machine are: HZ, H1, H2, H3 are 165-175°C, H4, H...

Embodiment 1

[0036] Take by weighing 400g molecular weight respectively and be 530,000, the P3 / 4HB copolymer (Tianjin Guoyun) and 1600g polylactic acid (Nature Works) that 4HB molar content is 20%, after mixing uniformly, extrude through twin-screw extruder, after extruding After cooling in ice water, use a granulator to cut pellets, the diameter of the pellets is about 3mm, and then inject the pellets with an injection molding machine; the setting parameters of the twin-screw are: host frequency 10Hz, feeding frequency 8Hz, from feeding port A to The temperature setting values of each section of the machine head are 0°C, 150°C, 160°C, 170°C, 180°C, 180°C, 180°C, 180°C; the setting parameters of the barrel temperature of the injection molding machine are: HZ, H1, H2, H3 is 170°C, H4 and H6 are 0°C, and the molded product is a light yellow translucent glossy solid. The mechanical properties of the obtained material: the elongation at break is 220.2%, the tensile strength is 44.2MPa, and th...

Embodiment 2

[0038] Take by weighing 1800g molecular weight respectively and be 530,000, the P3 / 4HB copolymer (Tianjin Guoyun) and 200g polylactic acid (Nature Works) that 4HB molar content is 20%, after mixing uniformly, extrude through twin-screw extruder, after extruding After cooling in ice water, use a granulator to cut pellets, the diameter of the pellets is about 3mm, and then inject the pellets with an injection molding machine; the setting parameters of the twin-screw are: host frequency 10Hz, feeding frequency 8Hz, from feeding port A to The temperature setting values of each section of the machine head are 0°C, 150°C, 160°C, 170°C, 180°C, 180°C, 180°C, 180°C; the setting parameters of the barrel temperature of the injection molding machine are: HZ, H1, H2, H3 The temperature is 170°C, H4 and H6 are non-heating zones, and the molded product is a translucent glossy solid. The elongation at break of the obtained material can reach 507.2%. It cannot be punched without notched impac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com