Marine cylinder lubricant composition

A technology of lubricating oil composition and cylinder, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of aggravating engine wear, affecting lubricating oil, and no application report of cylinder lubricating oil, achieving good compatibility and improving comprehensive The effect of lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

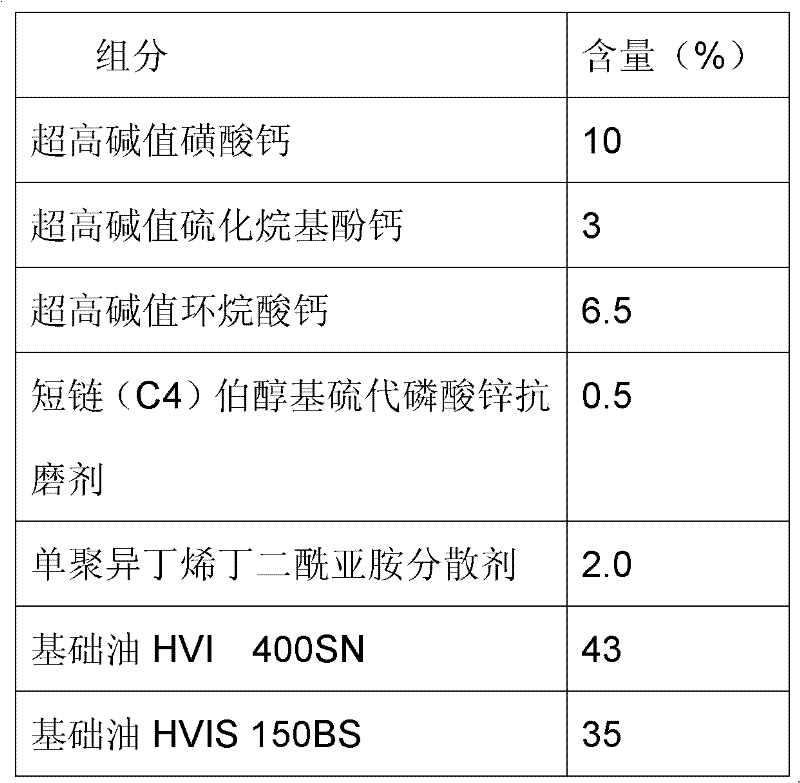

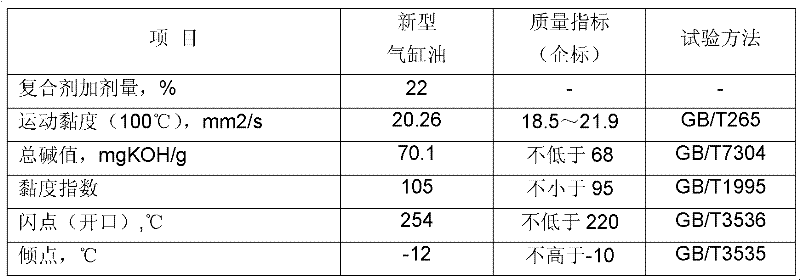

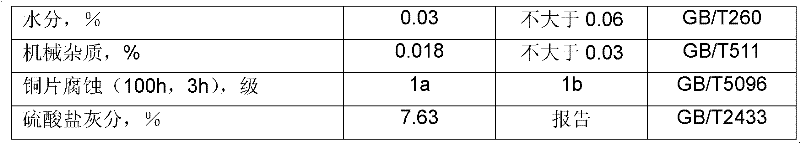

[0022] The following components and contents (weight percentage) are formulated into marine cylinder lubricating oil according to conventional techniques. Among them: the ultra-high base number sulfonate is a long-chain C20 linear alkylbenzene ultra-high base number calcium sulfonate with a base value of 395mgKOH / g; the ultra-high base number sulfurized alkyl phenolate is a long-chain alkyl C24 sulfurized phenol Calcium, base value is 310mgKOH / g; ultra-high base value naphthenate is ultra-high base value calcium naphthenate, base value is 390mgKOH / g; antiwear agent is short-chain (C4) primary alcohol thiophosphoric acid Zinc.

[0023]

Embodiment 2

[0025] The following components and contents (parts by weight) are formulated into a new marine lubricant formula according to conventional techniques.

[0026] Among them: the ultra-high base number sulfonate is a long-chain C24 linear alkylbenzene ultra-high base number calcium sulfonate with a base value of 430mgKOH / g; the ultra-high base number sulfurized alkyl phenolate is a long-chain alkyl C18 sulfurized phenol Calcium, base value is 290mgKOH / g; ultra-high base value naphthenate is ultra-high base value calcium naphthenate, base value is 420mgKOH / g; antiwear agent is long-chain (C16) secondary alcohol thiophosphoric acid Zinc.

[0027] Component

[0028] Base oil HVIS 150BS

Embodiment 3

[0030] The following components and contents (parts by weight) are formulated into a new marine lubricant formula according to conventional techniques. Among them: ultra-high base number sulfonates are long-chain (C20-24) linear alkylbenzene ultra-high base number calcium sulfonates, with a base value of 400mgKOH / g; ultra-high base number sulfurized alkyl phenates are long-chain alkanes Base (C18-24) sulfide calcium phenate, base value is 300mgKOH / g; ultra-high base value naphthenate is ultra-high base value calcium naphthenate, base value is 405mgKOH / g; antiwear agent is long chain ( C12) Secondary alcohol-based zinc thiophosphate.

[0031] Component

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com