Brewing process for Chinese wolfberry mead

The technology of wolfberry mead and process is applied in the field of brewing technology of wolfberry mead, which can solve the problem of not seeing wolfberry mead, and achieve the effects of low alcohol content, refreshing aroma and soft taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A brewing process of medlar honey wine, comprising the steps of:

[0021] First prepare the wolfberry extract juice: add the dried wolfberry fruit to 25 times the quality of the dried fruit in pure water, and cook it twice (after the first cooking, add 22 times the quality of water to the steamed wolfberry and cook again), to refine and extract the juice , and kept for 30 minutes after boiling each of the two cookings, then filtered to remove the remaining solid residue of wolfberry, and then combined the filtrates for use.

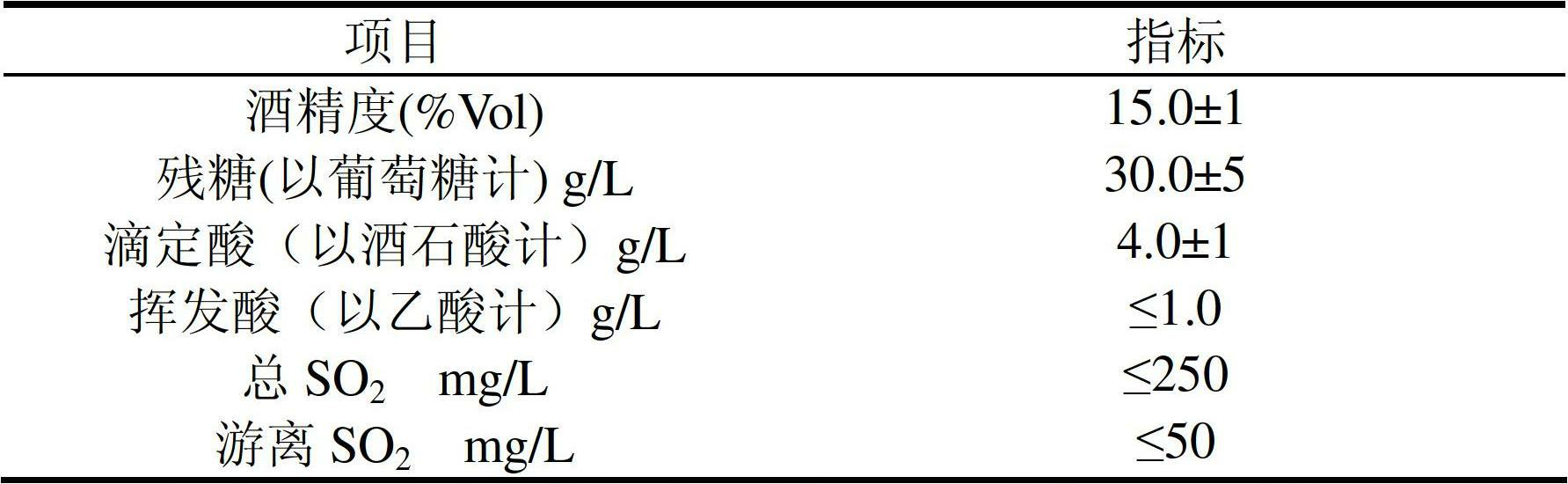

[0022] Put the wolfberry extract juice and jujube flower honey into the tank according to the volume ratio of 19:1, then add pectinase and SO 2 , the amount of pectinase added is 30mg / L (or according to the amount used in its instruction manual), SO 2 The amount of addition is 100mg / L, and then the total sugar and total acid of the juice to be fermented are measured. 4.0g / L, adjust the sugar content with white granulated sugar, adjust the total a...

Embodiment 2

[0031] A brewing process of medlar honey wine, comprising the steps of:

[0032] First prepare wolfberry extract juice: add dried wolfberry fruit to pure water 23 times the mass of dried fruit, and cook twice (after the first cooking, add 23 times the quality of water to the cooked wolfberry and cook again), to refine and extract the juice , and kept for 30 minutes after boiling each of the two cookings, then filtered to remove the remaining solid residue of wolfberry, and then combined the filtrates for use.

[0033] Put the wolfberry extract juice and acacia honey into the tank according to the volume ratio of 16:1, then add pectinase and SO 2 , the amount of pectinase added is 30mg / L, SO 2 The added amount is 300mg / L, and then the total sugar and total acid of the juice to be fermented are measured. 4.0g / L, adjust the sugar content with white granulated sugar, adjust the total acid and pH value with food-grade 99.5% citric acid to reach the standard index.

[0034] Take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com