Preparation method for disaccharide, tetrasccharide and hexaose of chondroitin sulfuric acid

A chondroitin sulfate and cartilage sulfate technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of few reports on the separation and purification of CS oligosaccharides, and few studies on single oligosaccharides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

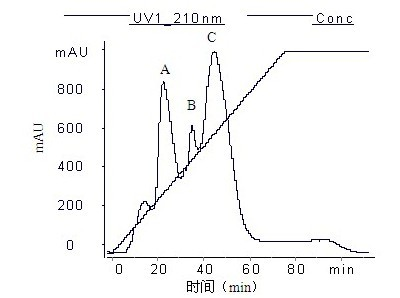

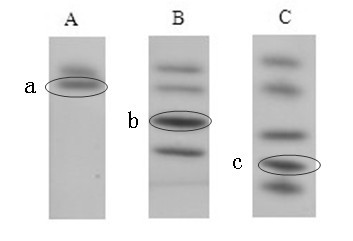

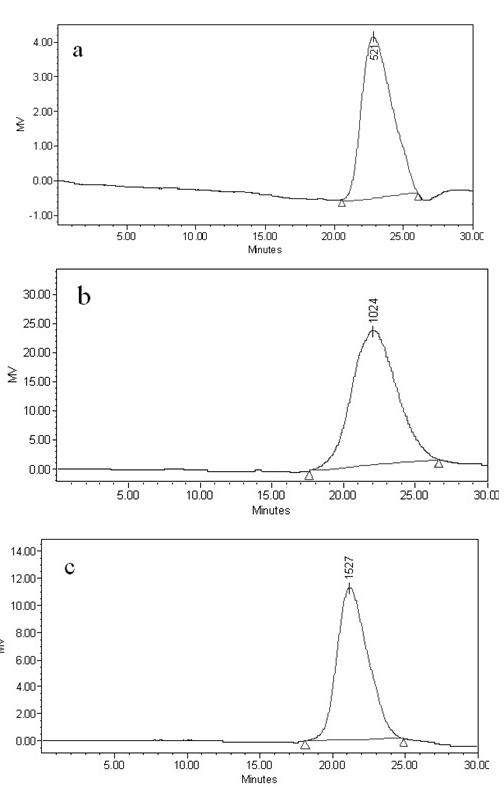

[0032] 1. Preparation of chondroitin sulfate oligosaccharides by enzymatic degradation

[0033] Dissolve 0.2 g of chondroitin sulfate in 10 mL of phosphate buffer with pH 5.9, and place it at 37 °C for 10 min to make it consistent with the reaction temperature, then add hyaluronidase (HAase, from bovine testis), making its enzyme activity 1.4×10 5 u / L, 150 rev / min shaking reaction for 22h. After the reaction, heat and boil for 20 minutes to inactivate the enzyme, centrifuge at 4000r / min for 15 minutes, take the supernatant and add 3 times the volume of 95% ethanol to precipitate, let it stand, dehydrate with 10mL absolute ethanol for 3 times, and vacuum dry to obtain chondroitin sulfate low Glycan A, and the total antioxidant activity (TOA) of the resulting degradation products was determined.

[0034] 2. Determination of total antioxidant activity

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com