Multilayer sound-absorption wedge having resonance sound absorption structure

A technology of resonance sound absorption and sound-absorbing wedges, applied in the directions of sound-generating equipment, layered products, instruments, etc., can solve the problems of increasing building wall load, heavy sound-absorbing wedges, inconvenient transportation and installation, etc. Acoustic performance, ease of transport and installation, effect of mass reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

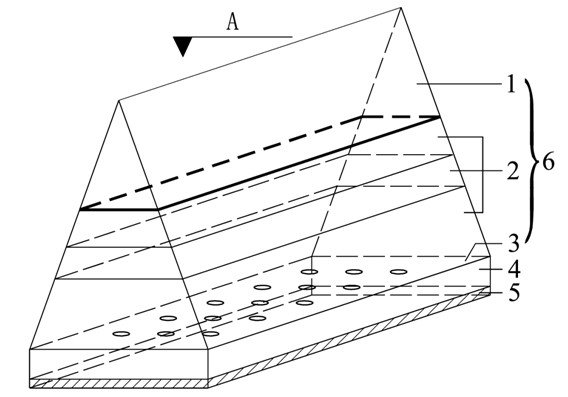

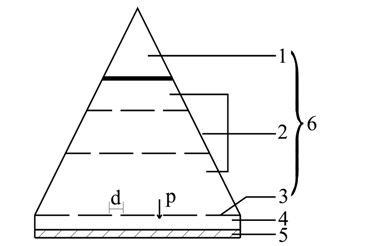

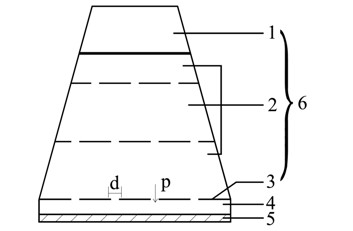

[0036] like Figure 1~2 It is a schematic structural diagram provided by Embodiment 1 of the present invention, figure 1 is a stereogram, figure 2 for figure 1 Sectional view in direction A.

[0037] like figure 1 , figure 2 As shown, the present invention includes a wedge body 6 and a rigid base 5. The wedge body 6 is composed of several layers of sound-absorbing materials whose characteristic impedance gradually changes from small to large. From the top down, there are impedance matching layers 1, The sound dissipating layer 2 and the perforated plate 3 can be bonded by pressing or high-temperature fusion or environmental glue, and together constitute the tip with a multi-layer structure. Between the perforated plate 3 and the rigid base 5 there is a cavity 4 . The perforated plate 3, the cavity 4 and the rigid base 5 constitute a resonant sound-absorbing structure. The rigid base 5 and the perforated plate 3 are linked by rivets.

[0038] The specific implementati...

Embodiment 2

[0052] like Figure 4 Shown is the structural schematic diagram provided by Embodiment 2 of the present invention. The difference from the sound-absorbing wedge structure of Embodiment 1 is that two wedge bodies are provided on a rigid base, and the cavity is divided into 6 sub-cavities, according to the acoustic principle, subdividing the cavity can further broaden the sound absorption frequency band and improve the sound absorption performance.

[0053] The separator in this embodiment can be made of the same material as the perforated plate, which can be stainless steel plate, aluminum plate, alloy plate, plastic plate, wood plate, plywood, gypsum board, glass plate or cardboard, etc., and its plate thickness can be installed according to the actual situation. It is determined that it is about 1-5mm; it is further explained that the number of sub-cavities is not limited in Embodiment 2 of the present invention.

Embodiment 3

[0055] like Figure 5 Shown is the structural schematic diagram provided by Embodiment 3 of the present invention. The difference from the sound-absorbing wedge structure of Embodiment 1 is that there are two wedge structures on a rigid base, and the cavity is filled with honeycomb interlayer. According to the acoustic According to the principle, filling the honeycomb interlayer can also further improve the sound absorption performance. The honeycomb interlayer in this embodiment can use aluminum alloy honeycomb layer, glass fiber reinforced plastic honeycomb layer or paper honeycomb layer and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Characteristic impedance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com