Denitration method for waste gas generated by burning system and denitration device thereof

A combustion system and denitration technology, which is applied in the field of pollution control of NOx-containing waste gas, can solve the problems of difficult adjustment of reaction conditions, difficult control of reaction quality, and high cost of use, and achieves the advantages of shortening reaction time, lowering temperature and saving energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

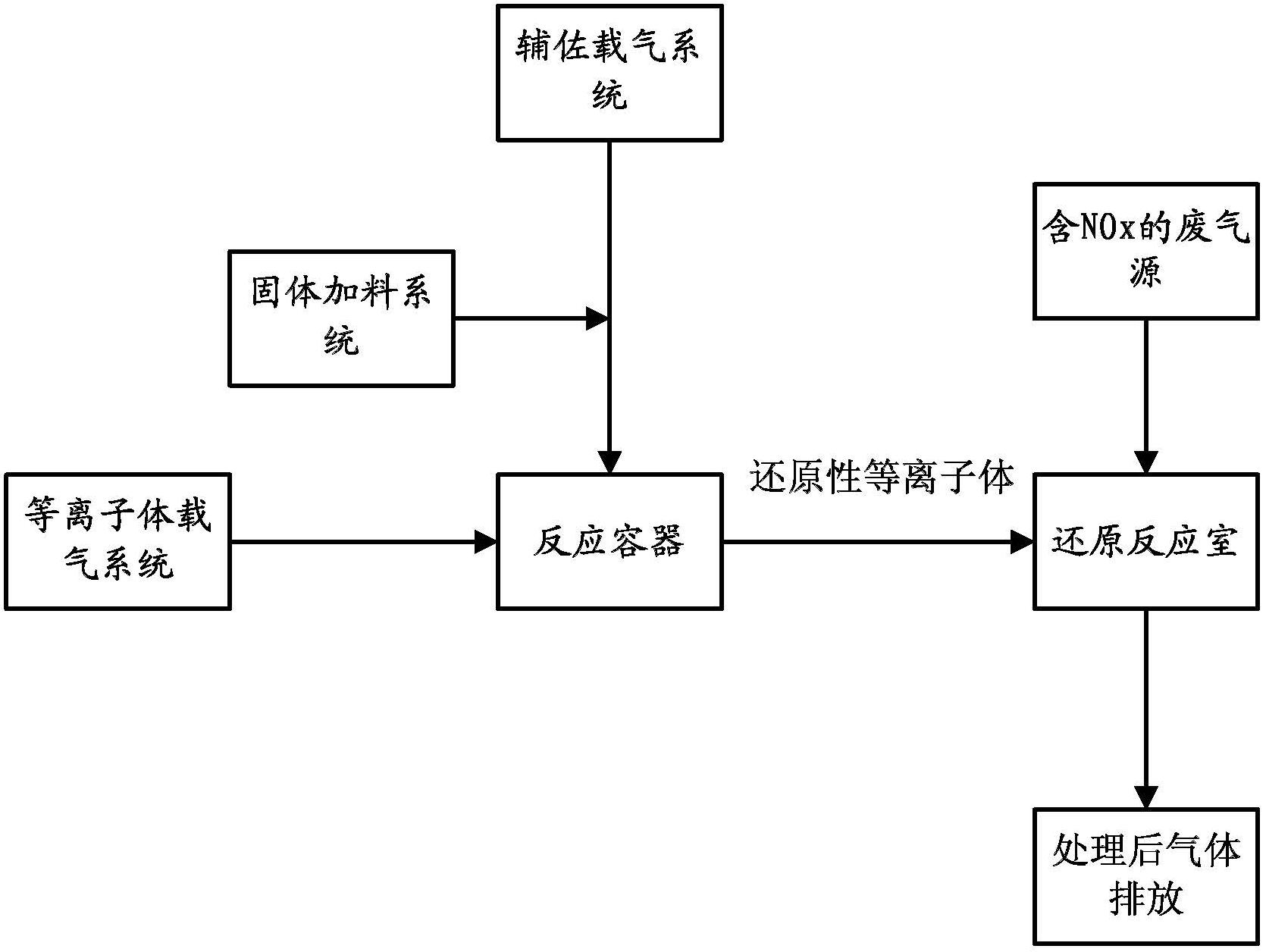

[0069] Such as figure 1 As shown, the solid reducing agent is added to the auxiliary carrier gas system by using the solid feeding system, and the auxiliary carrier gas system brings the solid reducing agent into the electrode area in the plasma reaction vessel or the reaction area behind the electrode area. In this area, the solid The reducing agent and the plasma from the plasma carrier gas system collide and exchange energy, so that they can be gasified and converted into plasma or excited activated molecules in whole or in part. This reducing plasma is introduced into the NO-containing plasma. x The exhaust gas channel, and enter the reduction reaction chamber together with the exhaust gas, under the action of the catalyst (SCR method) or a certain temperature (SNCR method), the NO x reduced to N 2 and CO 2 And water and other harmless gases, the treated gas is discharged through the subsequent discharge device.

Embodiment 2

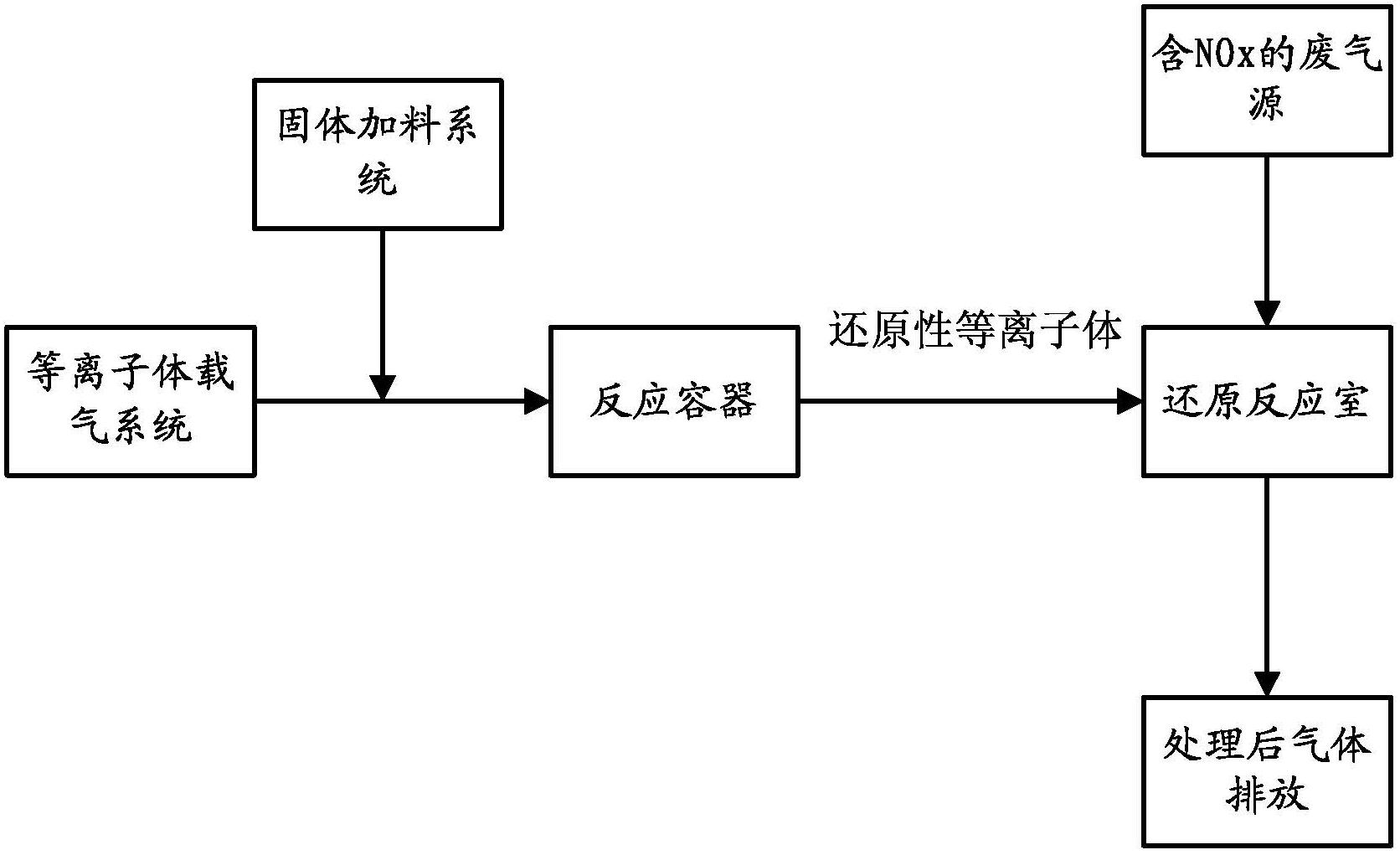

[0071] Such as figure 2 As shown, the solid reducing agent is directly added to the plasma carrier gas system by using the solid feeding system, and the plasma carrier gas brings the solid reducing agent into the electrode area in the plasma reaction vessel or the reaction area behind the electrode. Subsequent steps are the same as in Example 1.

Embodiment 3

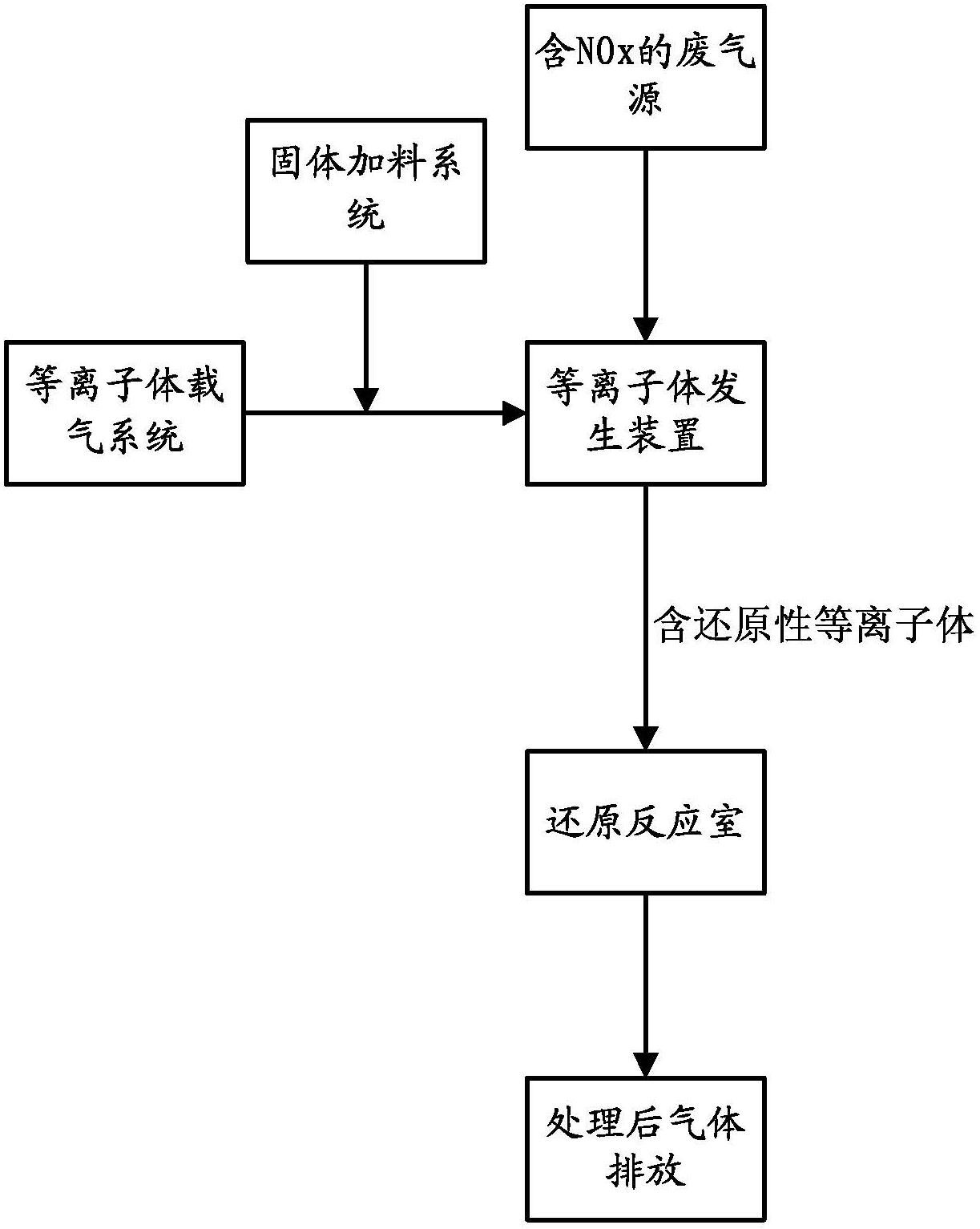

[0073] Such as image 3 As shown, the open plasma reaction device is adopted, and the plasma reaction device is placed in the exhaust gas passage, and the generated reducing plasma is quickly in contact with the exhaust gas. This process arrangement is especially suitable for plasma nozzles, plasma showers, and plasma torches. Applications of plasma devices. In such an arrangement, once the plasma is generated, it can quickly enter the reduction reaction, preventing the plasma from being quenched and annihilated. Subsequent steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com