Preparation method of monodisperse granular amorphous nanometer TiO2

An amorphous, monodisperse technology, applied in the preparation of amorphous nano-TiO2, the preparation of monodisperse rice-like amorphous nano-TiO2, can solve the problems of difficult to control size, structure and morphology, harsh reaction conditions, etc., to achieve shape Uniformity, low preparation cost, good monodispersity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Add 0.05 mol·L -1 Ti(SO 4 ) 2 and 10 g L -1 Dissolve polyvinylpyrrolidone in water, add 3.5% (volume ratio) H 2 o 2 as a complexing agent;

[0019] (2) Transfer the above mixed solution to a tetrafluoroethylene-lined autoclave, heat at a constant temperature of 100 °C for 1 h, then raise the temperature to 200 °C for 1 h, and finally adjust to 80 °C for 20 h to obtain a TiO-containing 2 the mixture;

[0020] (3) The above-mentioned containing TiO 2 After the mixture was cooled, it was centrifuged at 10,000 r / min for 10 min, the upper layer was discarded, and washed three times with water and ethanol to obtain white TiO 2 Precipitate;

[0021] (4) Put the precipitate obtained in step (3) into a drying oven at 80 °C for 24 h to obtain monodisperse amorphous nano-TiO 2 .

Embodiment 2

[0023] (1) Dilute 1.0 mol·L -1 Ti(SO 4 ) 2 and 10 g L -1 Dissolve polyvinylpyrrolidone in water, add 7% (volume ratio) of H 2 o 2 as a complexing agent;

[0024] (2) Transfer the above mixed solution to a high-pressure reactor lined with tetrafluoroethylene, heat at 100 °C for 1 h, then raise the temperature to 200 °C for 1 h, and finally adjust to 80 °C for 20 h to obtain TiO-containing 2 the mixture;

[0025] (3) The above-mentioned containing TiO 2 After the mixture was cooled, it was centrifuged at 10,000 r / min for 10 min, the upper layer was discarded, and washed three times with water and ethanol to obtain white TiO 2 Precipitate;

[0026] (4) Put the precipitate obtained in step (3) into a drying oven at 80 °C for 24 h to obtain monodisperse amorphous nano-TiO 2 .

[0027]

Embodiment 3

[0029] (1) Add 0.05 mol·L -1 Ti(SO 4 ) 2 and 10 g L -1 Dissolve polyvinylpyrrolidone in water, add 3.5% (volume ratio) H 2 o 2 ;

[0030] (2) Transfer the above mixed solution to a high-pressure reactor lined with tetrafluoroethylene, heat at a constant temperature of 100 °C for 1 h, then raise the temperature to 240 °C for 30 min, and finally adjust to 60 °C for 24 h to obtain a TiO-containing 2 the mixture;

[0031] (3) The above-mentioned containing TiO 2 After the mixture was cooled, it was centrifuged at 10,000 r / min for 10 min, the upper layer was discarded, and washed three times with water and ethanol to obtain white TiO 2 Precipitate;

[0032] (4) Put the precipitate obtained in step (3) into a drying oven at 80 °C for 24 h to obtain monodisperse amorphous nano-TiO 2 .

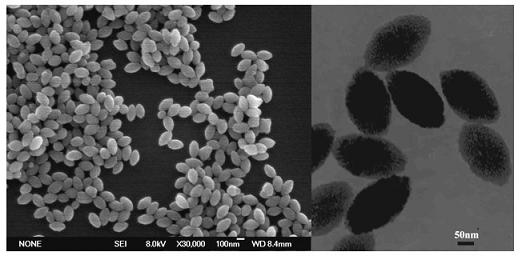

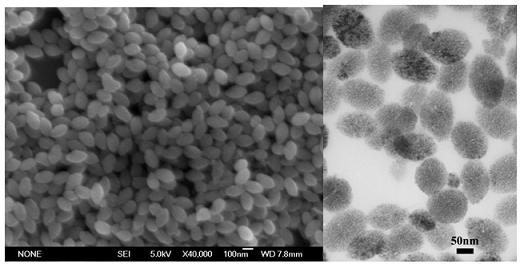

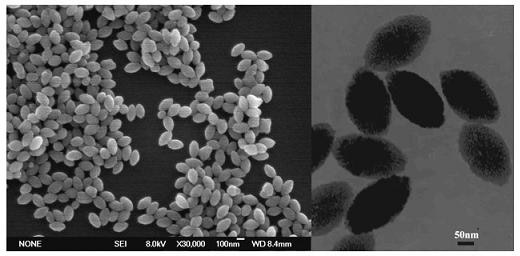

[0033] The powder X-ray diffraction pattern of sample does not appear obvious diffraction peak, shows that the TiO prepared by the method of the present invention 2 The product is amorphou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com