Environment-friendly rubber belt

A kind of rubber belt, environmental protection technology, applied in the direction of rubber layered products, recovery of fat oil/fatty acid from waste materials, layered products, etc., can solve the problems of stagnant prices, slow development speed, regardless of product quality issues, etc. Achieve the effect of reducing production cost and improving processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

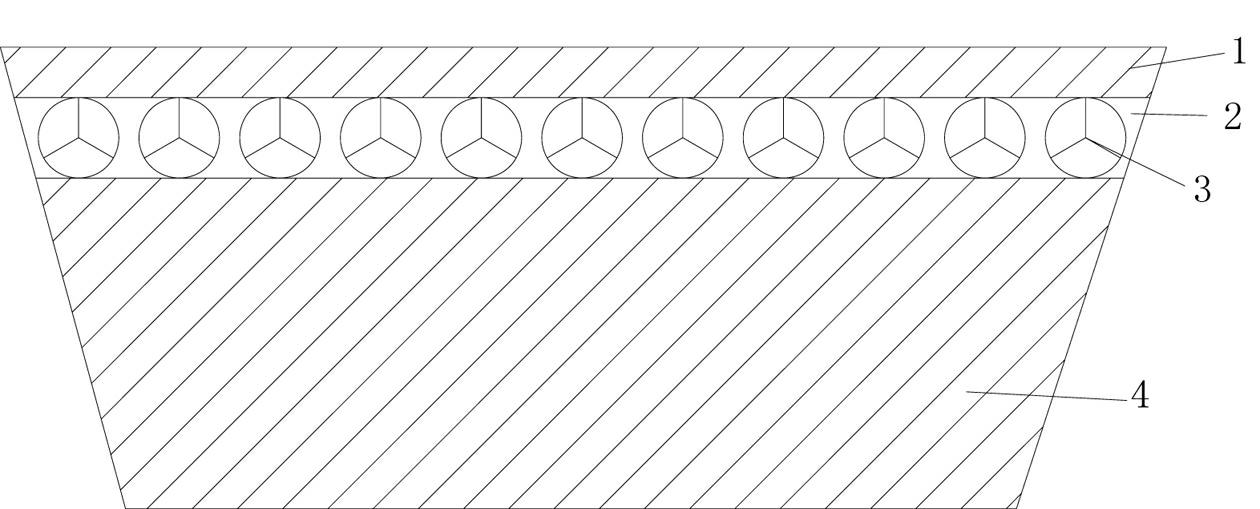

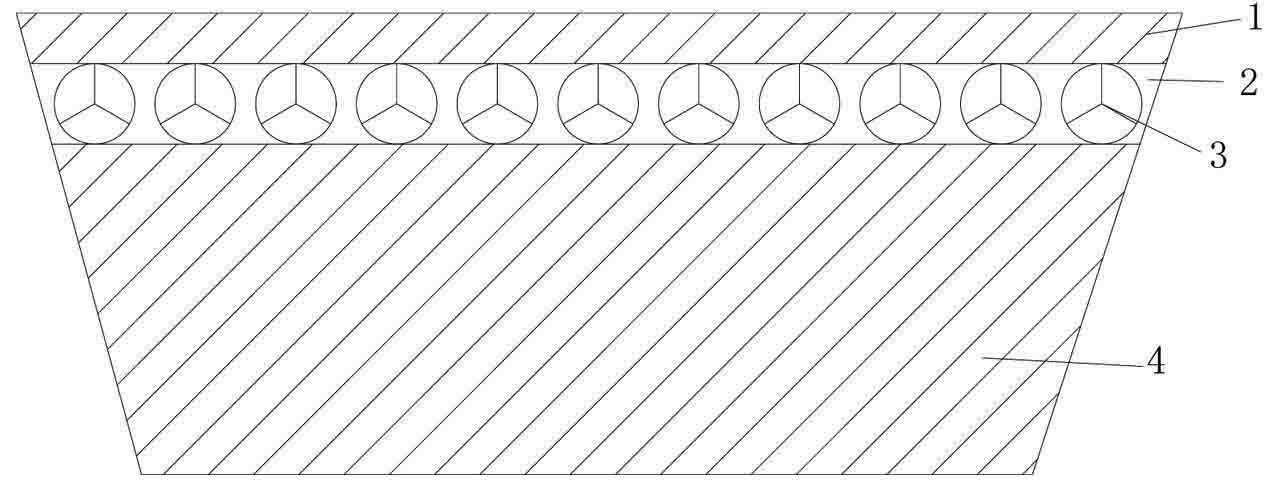

[0047] Eco-friendly rubber belts, such as figure 1 As shown, it includes a top adhesive layer 1 , a buffer layer 2 , a tensile layer 3 and a primer layer 4 .

[0048] The top adhesive layer 1 and the bottom adhesive layer 4 contain the following raw materials by weight:

[0049] Neoprene 1211 100 parts;

[0050] 40 parts of carbon black 330 and carbon black 774;

[0051] 30 parts of short fiber;

[0052] 5 parts of active magnesium oxide;

[0053] Anti-aging agent RD, anti-aging agent 4010NA 4 copies;

[0054] 4 parts of active zinc oxide;

[0055] 1 part of stearic acid;

[0056] 4 parts of dispersant AT-C;

[0057] 10 copies of "Gutter Oil" extract.

[0058] The buffer layer 2 includes the following raw materials in parts by weight:

[0059] Neoprene 1211 100 parts;

[0060] Carbon black 330, carbon black 550 60 parts;

[0061] 5 parts of active magnesium oxide;

[0062] Anti-aging agent RD, anti-aging agent 4010NA 4 copies;

[0063] 3 parts of vulcanizing agent...

Embodiment 2

[0070] Eco-friendly rubber belts, such as figure 1 As shown, it includes a top adhesive layer 1 , a buffer layer 2 , a tensile layer 3 and a primer layer 4 .

[0071] The top adhesive layer 1 and the bottom adhesive layer 4 contain the following raw materials by weight:

[0072] Neoprene 1211 100 parts;

[0073] 50 parts of carbon black 330 and carbon black 774;

[0074] 30 parts of short fiber;

[0075] 4 parts of activated magnesium oxide;

[0076] 3 copies of antioxidant RD, antioxidant 4010NA;

[0077] 5 parts of active zinc oxide;

[0078] 2 parts of stearic acid;

[0079] 3 parts of dispersant AT-C;

[0080] 10 copies of "Gutter Oil" extract.

[0081] The buffer layer 2 includes the following raw materials in parts by weight:

[0082] Neoprene 1211 100 parts;

[0083] 60 parts of carbon black 330 and carbon black 774;

[0084] 5 parts of active magnesium oxide;

[0085] 3 copies of antioxidant RD, antioxidant 4010NA;

[0086] 1 part of active zinc oxide;

...

Embodiment 3

[0092] Eco-friendly rubber belts, such as figure 1 As shown, it includes a top adhesive layer 1 , a buffer layer 2 , a tensile layer 3 and a primer layer 4 .

[0093] The top adhesive layer 1 and the bottom adhesive layer 4 contain the following raw materials by weight:

[0094] Neoprene 1211 100 parts;

[0095] 50 parts of carbon black 330 and carbon black 774;

[0096] 30 parts of short fiber;

[0097] 4 parts of activated magnesium oxide;

[0098] 3 copies of antioxidant RD, antioxidant 4010NA;

[0099] 5 parts of active zinc oxide;

[0100] 2 parts of stearic acid;

[0101] 3 parts of dispersant AT-C;

[0102] 10 parts of swill oil extract.

[0103] The buffer layer 2 includes the following raw materials in parts by weight:

[0104] Neoprene 1211 100 parts;

[0105] 60 parts of carbon black 330 and carbon black 774;

[0106] 5 parts of active magnesium oxide;

[0107] 3 copies of antioxidant RD, antioxidant 4010NA;

[0108] 1 part of active zinc oxide;

[010...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com