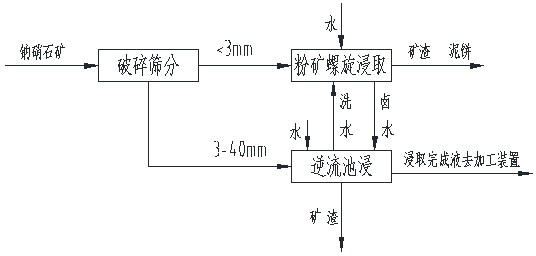

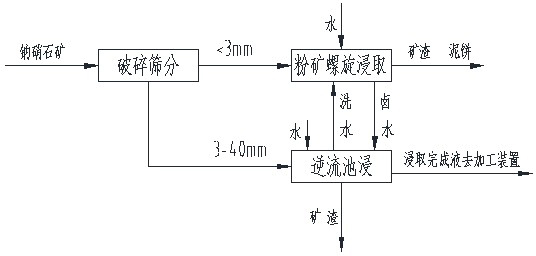

Process for producing sodium nitrate from soda niter in size-fraction leaching manner

A production process and technology of sodium nitrate, applied in the preparation of alkali metal nitrates and other directions, can solve the problems of low system recovery rate, low brine concentration, large energy consumption for leaching, etc., achieve high leaching yield, reduce water consumption, The effect of reducing energy consumption and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] (1) Ore crushing and screening: the sodium saltpeter ore containing sodium nitrate grade of 4.70% is crushed by a two-stage crushing process, and then sieved to obtain granular ore of 3mm to 40mm and fine ore of 3mm or less;

[0028] The two-stage crushing process is firstly crushed by coarse crushing equipment, and then medium and fine crushing equipment is used for treatment, the coarse crushing equipment is selected as a flange crusher, and the medium and fine crushing equipment is selected as a cone crusher;

[0029] (2) Granular ore leaching: After crushing the 3mm to 40mm ore granules obtained in step (1), the distributing machine for ore granules from 3mm to 40mm is loaded into the leaching tank, and then washed and leached with clean water or processing plant miscellaneous water. The leaching temperature is increased step by step, from room temperature washing to 50℃ leaching; the leaching time of each stage is 9 h...

Embodiment 2

[0040] The difference between this embodiment and Example 1 is: in step (2), the solid-liquid mass ratio of granular ore leaching is controlled to be 1:0.27, and in step (3), fine ore leaching is used 8% of the raw material quality of fine ore is washed with clean water, and the waste residue is NaNO 3 The mass content is 0.85%, efflux; others are the same as in Example 1.

[0041] Compared with the traditional process, this embodiment saves water up to 35% and increases the yield of sodium nitrate by 6%; the concentration of brine in the finished leaching solution reaches 339.2 g / l.

Embodiment 3

[0043] The difference between this embodiment and embodiment 1 is that in step (1), the grade of sodium saltpeter is 7.96%, and in step (2), the mass ratio of solid-liquid leaching of granular ore is controlled to be 1:0.3 , In step (3), in the leaching of fine ore, 8% of the raw material quality of fine ore is used for washing, and the waste residue is NaNO 3 The mass content is 0.87%, efflux; others are the same as in Example 1.

[0044] Compared with the traditional process, this embodiment saves water up to 33% and increases the yield of sodium nitrate by 7%; the concentration of brine in the leaching solution reaches 332.4g / l.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com