Orange red fluorescent powder for LED (Light Emitting Diode) and preparation method thereof

A fluorescent powder and orange-red technology, applied in the field of rare earth luminescent materials, can solve the problems of poor color rendering, low efficiency, and unstable performance, and achieve stable physical and chemical properties, high energy conversion efficiency, and simple synthesis methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

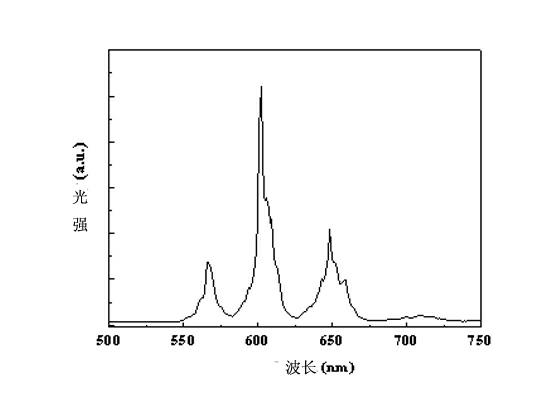

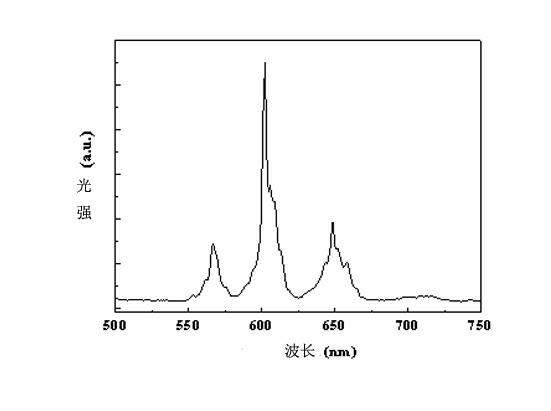

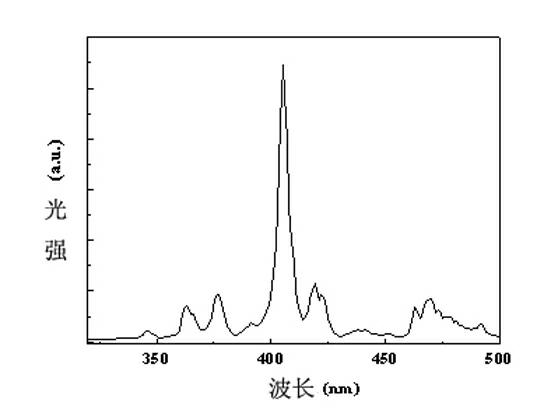

[0019] Embodiment 1: Weighing CaCO 3 4.5321g, TeO 2 7.3736g, Li 2 CO 3 0.0171, Sm 2 o 3 0.0806g, the above raw materials are all analytically pure. After the weighed raw materials are mixed and ground evenly, they are put into an alumina crucible and roasted in the air, and kept at 650°C for 3 hours. After cooling, take it out and crush it, grind it, wash it with water to remove impurities, and dry it to get the chemical composition of Ca 0.98 Li 0.01 TeO 3 : 0.01Sm 3+ orange-red phosphors for LEDs. Its emission spectra at 405 nm and 375 nm light excitation are shown in figure 1 with figure 2 , the main emission peak is 602 nm. The excitation spectrum obtained by monitoring the 602 nm emission is shown in image 3 . It can be seen from the figure that the phosphor can be effectively excited by ultraviolet or purple light in the range of 340 nm to 420 nm, and has a wide range of uses.

Embodiment 2

[0020] Embodiment 2: Weighing CaC 2 o 4 11.0646g, TeO 2 4.7867g, Na 2 C 2 o 4 0.1206g, Sm 2 o 3 0.3138g, the above raw materials are all analytically pure. After the weighed raw materials are mixed and ground evenly, they are put into an alumina crucible and roasted in the air, and kept at 700°C for 1 hour. After cooling, take it out and crush it, grind it, wash it with water to remove impurities, and dry it to get the chemical composition of Ca 2.88 Na 0.06 TeO 6 : 0.06Sm 3+ orange-red phosphors for LEDs.

Embodiment 3

[0021] Embodiment 3: Weighing Sr(NO 3 ) 2 7.5711g, TeO 2 6.0758g, Li 2 CO 3 0.0423g, Sm(NO 3 ) 3 0.3841g, the above raw materials are all analytically pure. After the weighed raw materials are mixed and ground evenly, they are put into an alumina crucible and roasted in the air, and kept at 700°C for 3 hours. After cooling, take it out and crush it, grind it, wash it with water to remove impurities, and dry it to get the chemical composition of Sr 0.94 Li 0.03 TeO 4 : 0.03Sm 3+ orange-red phosphors for LEDs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com