Inorganic salt etching solution used for electrochemically etching highly fine lines

A technology of inorganic salt and etching solution, applied in the field of electronic industry application, can solve the problems such as the inability to meet the requirements of high precision, and achieve the effects of stable etching speed, simple preparation method and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of inorganic salt etching solution for electrochemically etching high-precision circuits, wherein the concentration of potassium chloride in the inorganic salt etching solution is 40 g / L, the concentration of potassium nitrite is 40 g / L, and the concentration of potassium phosphate is 40 g / L g / L, the concentration of complexing agent HEDP is 100 g / L, and the concentration of methanol is 100 g / L.

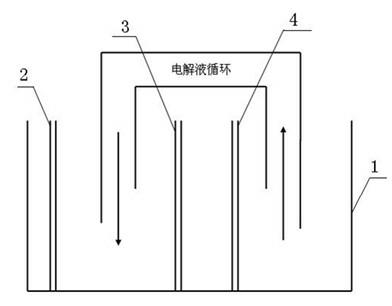

[0029] Such as figure 1 As shown, the electrochemical etching device consists of electrolytic cell (1), cathode (2), current distribution guide plate (3), anode (that is, etched circuit board) (4), electrolyte circulation pipeline and electrolyte circulation pump And so on. Anodic product Cu during etching 2+ Dissolved in the electrolyte, the cathode copper ions are reduced and deposited on the cathode from the solution. Electrolyte can always maintain the best state of stability.

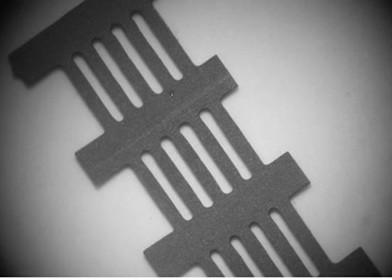

[0030] The above-mentioned inorganic salt etching solution is combined with an elect...

Embodiment 2

[0033]A kind of inorganic salt etching solution for electrochemically etching high-precision circuits, wherein the concentration of potassium chloride in the inorganic salt etching solution is 40 g / L, the concentration of potassium nitrite is 40 g / L, and the concentration of potassium phosphate is 40 g / L g / L, the concentration of complexing agent disodium EDTA is 100 g / L, and the concentration of ethanol is 100 g / L.

[0034] The above-mentioned inorganic salt etching solution is combined with an electrochemical etching device. The copper foil of the printed circuit board is used as the anode, and the graphite sheet is used as the cathode. The area ratio of the cathode and the anode is 10:1. At 30°C, the printed circuit board sample was etched by mechanical stirring etching, and the copper foil engraving time and potential value had a linear relationship.

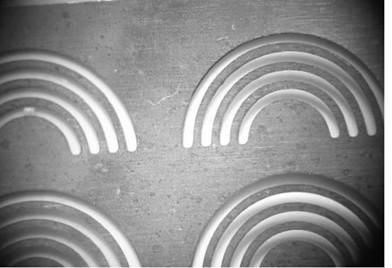

[0035] Under the potential of 10V, the time required to carve through the arc-shaped printed circuit board is 40 s, which ...

Embodiment 3

[0037] A kind of inorganic salt etching solution for electrochemical etching, wherein the concentration of potassium chloride in the inorganic salt etching solution is 40 g / L, the concentration of potassium nitrite is 40 g / L, and the concentration of potassium phosphate is 40 g / L , The concentration of the complexing agent sodium citrate is 100 g / L, and the concentration of acetone is 100 g / L.

[0038] The above-mentioned inorganic salt etching solution is combined with an electrochemical etching device. The copper foil of the printed circuit board is used as the anode, and the stainless steel sheet is used as the cathode. The area ratio of the cathode and the anode is 10:1. At 10°C, the printed circuit board sample is etched by spray etching, and the copper foil engraving time has a linear relationship with the potential value. After electrochemical etching in this inorganic salt etching solution, the appearance of the circuit board is neat and clean, the line spacing of 0.2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com