Preparation process of Nd-Fe-B permanent magnet and magnet prepared by using same

A preparation process, nd-fe-b technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as low magnetization, hindering application fields, and being limited in several places

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

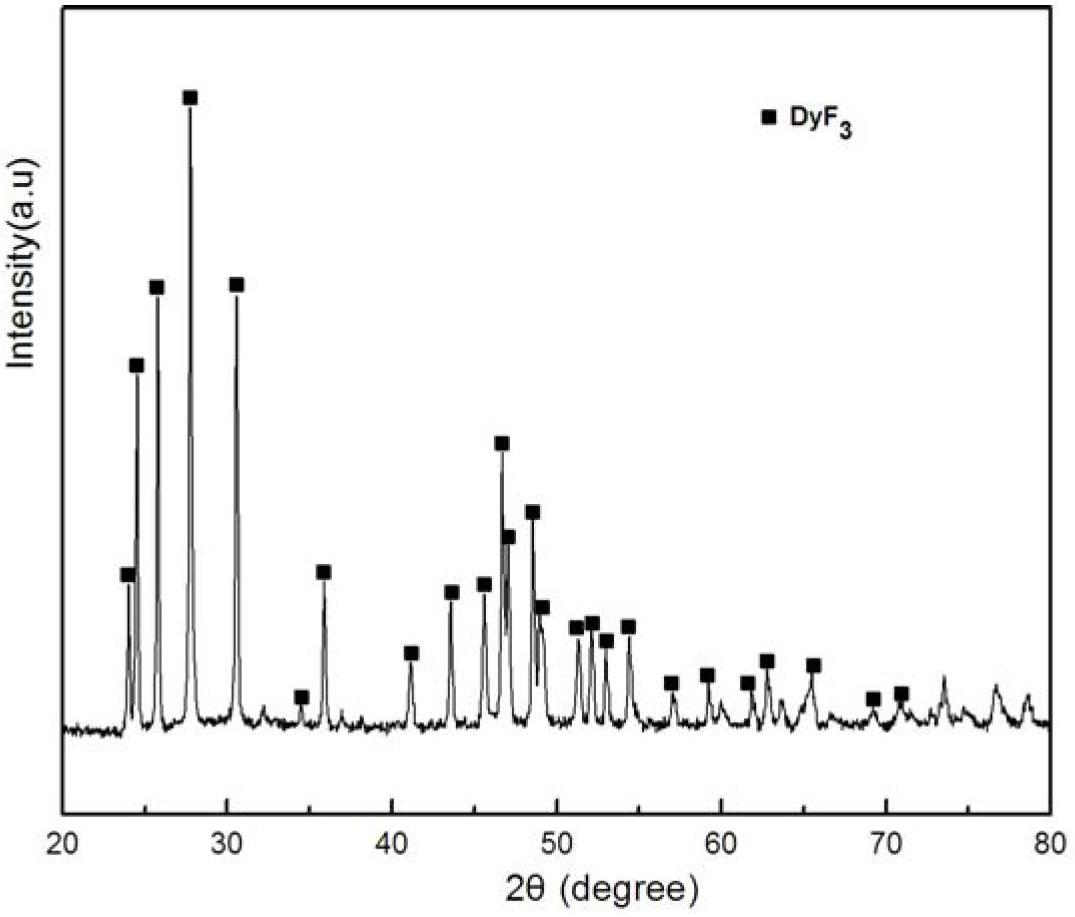

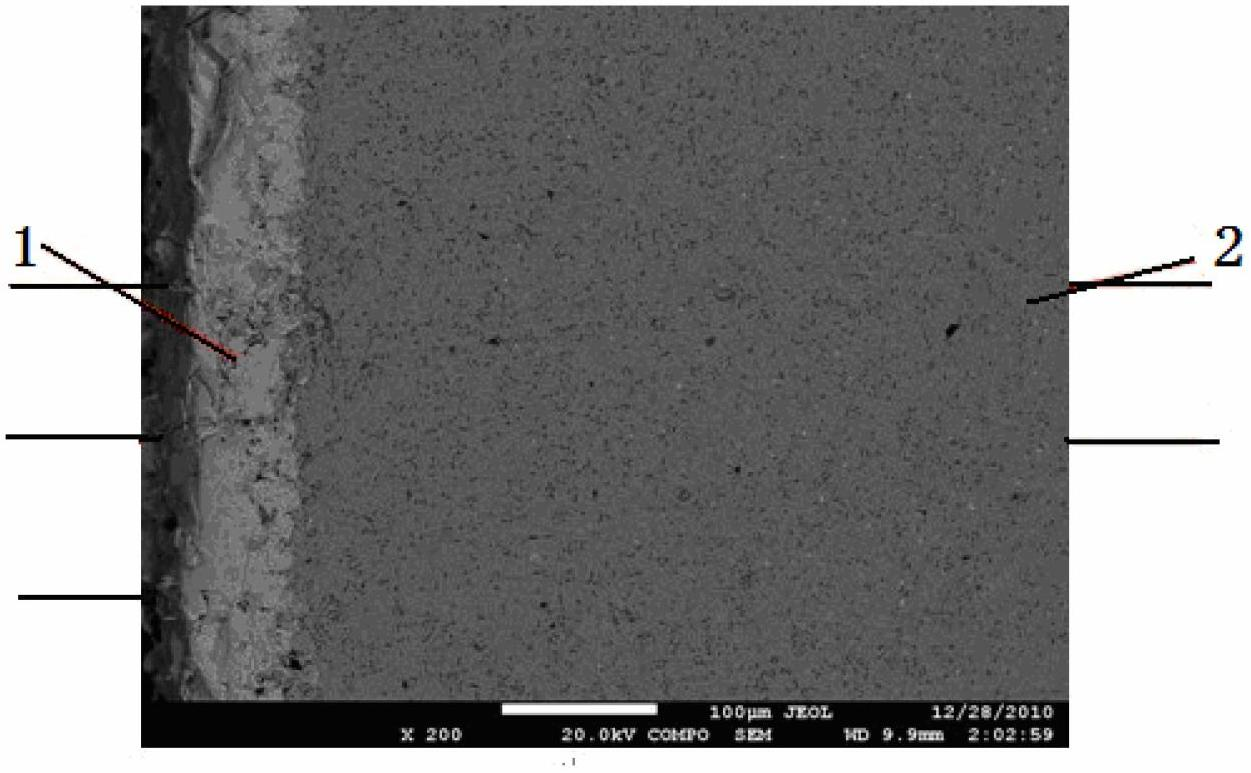

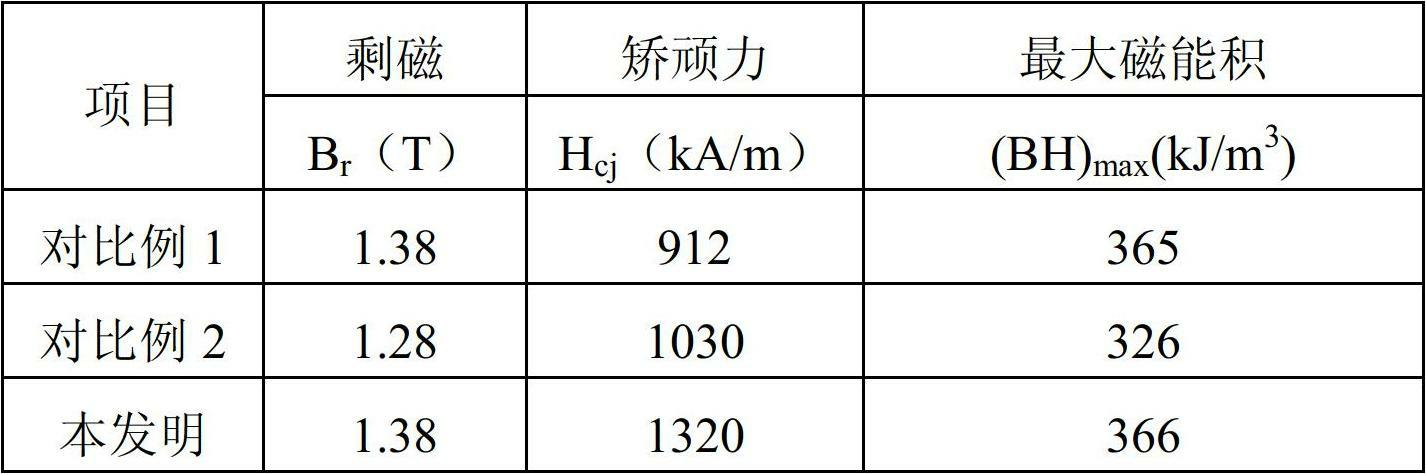

Embodiment 1

[0040] Select raw materials according to the ingredients shown in Table 1-1, and prepare NdR through the steps of smelting, powder making, molding and sintering a FeMB magnets, processed by wire cutting into 10×10×7 (7 is the c-axis direction, unit mm) magnets; add Tb in the container 2 o 3 powder and nitric acid, Tb 2 o 3 The molar ratio with nitric acid is 1:6, the concentration of nitric acid is 0.5mol / L, stir to make Tb 2 o 3 All dissolved; add ethylenediaminetetraacetic acid solution (EDTA), R b 2 o3 The molar ratio of EDTA and EDTA is 1:2, stirring for 600s to make EDTA and Tb in the solution 3+ A complexation reaction occurs to generate EDTA-Tb 3+ Complex ion, then add NH 4 F solution, R b 2 o 3 with NH 4 The molar ratio of F is 1:10, stir for 600s to obtain a clear solution, immerse the magnet in this solution, keep the solution in the container for 120s, and keep the temperature at 40°C, and react on the surface of the magnet to form uniform TbF 3 Thin fi...

Embodiment 2

[0046] Select raw materials according to the ingredients shown in Table 2-1, and prepare NdR through the steps of smelting, powder making, molding and sintering a FeMB magnets, processed by wire cutting into 10×10×8 (8 is the c-axis direction, unit mm) magnets, add Tb in the container 2 o 3 powder and nitric acid, Tb 2 o 3 The molar ratio with nitric acid is 1:15, the concentration of nitric acid is 6mol / L, stir to make Tb 2 o 3 All dissolved, add ethylenediaminetetraacetic acid solution (EDTA), Tb 2 o 3 The molar ratio with EDTA is 1:10, stir for 100s, make EDTA and Tb in the solution 3+ A complexation reaction occurs to generate EDTA-Tb 3+ Complex ion, then add NH 4 F solution, Tb 2 o 3 with NH 4 The molar ratio of F is 1:2, stir for 100s to obtain a clear solution, immerse the magnet in this solution, keep the solution in the container for 600s, and keep the temperature at 90°C, and react on the surface of the magnet to form uniform TbF 3 Thin film, film thickne...

Embodiment 3

[0052] Select raw materials according to the ingredients shown in Table 3-1, and prepare NdR through smelting, powder making, molding, and sintering steps a FeMB magnets, processed by wire cutting into 10×10×1.5 (1.5 is the c-axis direction, unit mm) magnets, add Tb in the container 2 o 3 powder and nitric acid, Tb 2 o 3 The molar ratio with nitric acid is 1:10, the concentration of nitric acid is 1mol / L, stir to make Tb 2 o 3 All dissolved, add ethylenediaminetetraacetic acid solution (EDTA), Tb 2 o 3 The molar ratio of EDTA and EDTA is 1:3, stirring for 60s to make EDTA and Tb in the solution 3+ A complexation reaction occurs to generate EDTA-Tb 3+ Complex ion, then add NH 4 F solution, Tb 2 o 3 with NH 4 The molar ratio of F is 1:7, stir for 50s to obtain a clear solution, immerse the magnet in this solution, keep the solution in the container for 200s, and keep the temperature at 40°C, and react on the surface of the magnet to form uniform TbF 3 Thin film, film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com