Medium array antenna

An array antenna and dielectric column technology, which is applied in the field of dielectric array antennas, can solve the problems of high price, difficult processing, complex structure of dielectric rods, etc., and achieve the effects of saving production cost, easy processing and reducing processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

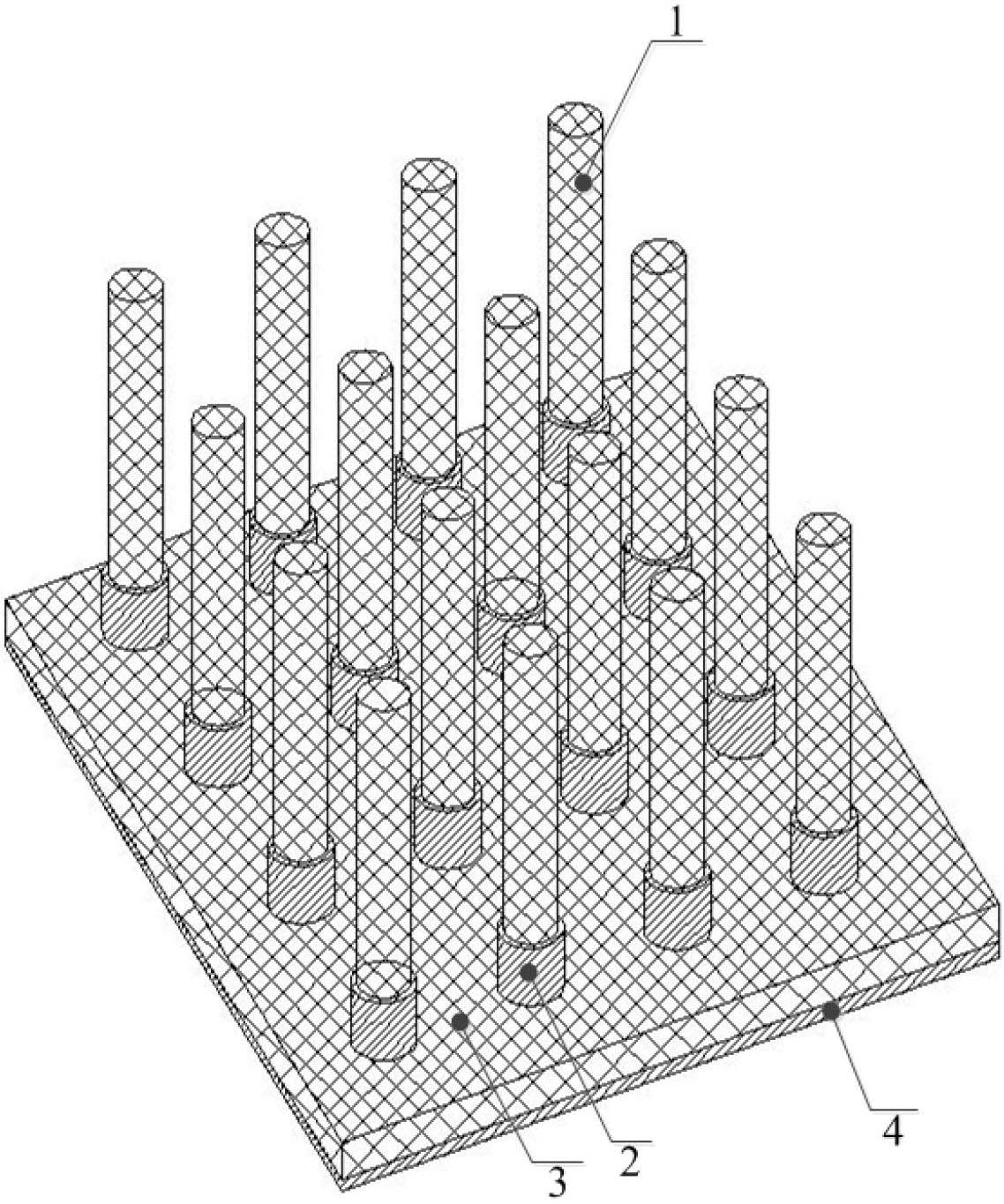

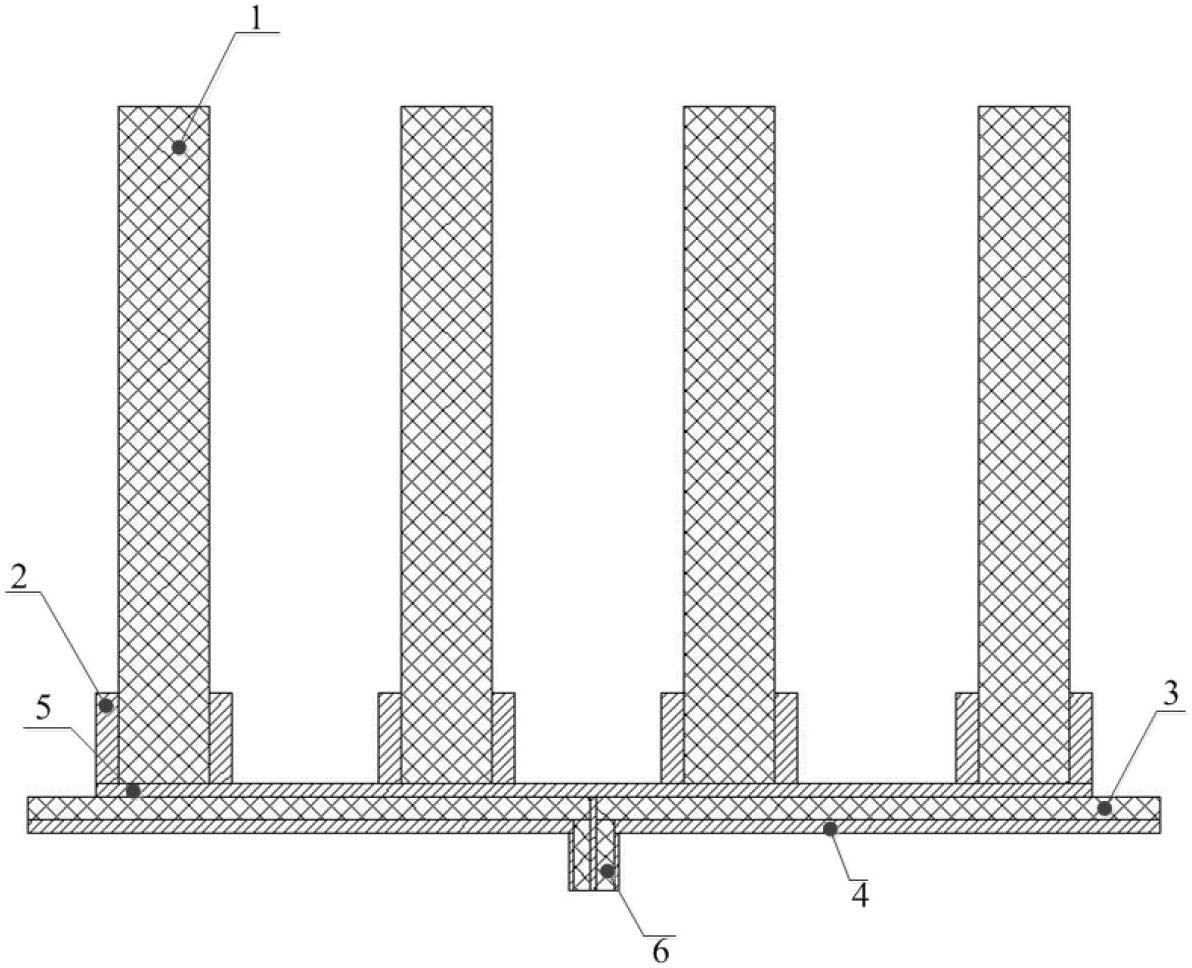

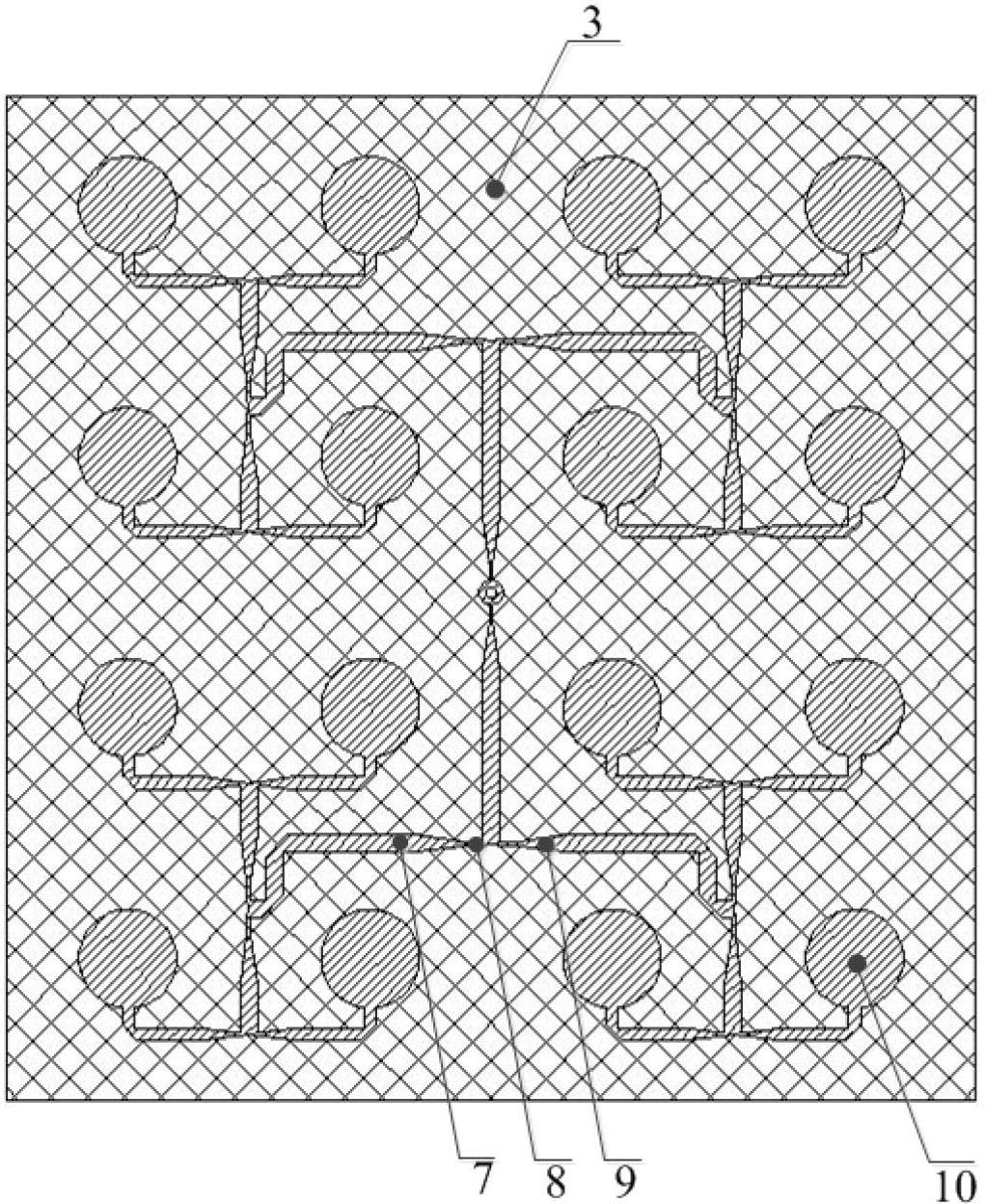

[0029] Such as Figure 1~3 As shown, the dielectric pillar array antenna uses 4×4 cylindrical dielectric pillars 1 as the antenna radiation unit; the height of the dielectric pillars is 80mm, and the radius is 4.4mm. The distance between the centers forms an antenna array; the array antenna uses a microstrip parallel feed network 5 to realize equal-amplitude and in-phase feed to the dielectric column; the microstrip parallel feed network 5 is printed on the dielectric layer 3 of the printed circuit board; the coaxial line 6 The inner conductor passes through the metal formation 4, the dielectric layer 3 is connected to the microstrip parallel feed network 5; the outer conductor of the coaxial line 6 is connected to the metal formation 4; a metal sleeve 2 is installed at the end of each dielectric column, and the metal sleeve is welded on On the circular metal patch 10 , the circular metal patch is printed on the dielectric layer. On the one hand, the metal sleeve fixes the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com