Device and method for producing nuisanceless bean sprouts by adopting extremely-low-frequency pulsed electric field

A technology of pulsed electric field and extremely low frequency, which is applied to the device for rapid production of pollution-free sprouts, the device for producing pollution-free sprouts, and the field of production of pollution-free sprouts. It can solve the problems of chemical pollution, low yield, and slow growth of sprouts. , to achieve the effects of neat and rapid growth, increased yield, and avoid mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The seeds of Zhonglv No. 2 mung bean were treated with 0.2% HgCl 2 Disinfect for 2 minutes, fully imbibition in distilled water after washing. Select uniform seeds and place them evenly in a petri dish. Place a piece of medium-speed filter paper at the bottom of the petri dish, add an appropriate amount of distilled water, and place them in a constant temperature incubator (25±0.2°C) for dark cultivation. Add distilled water regularly every day.

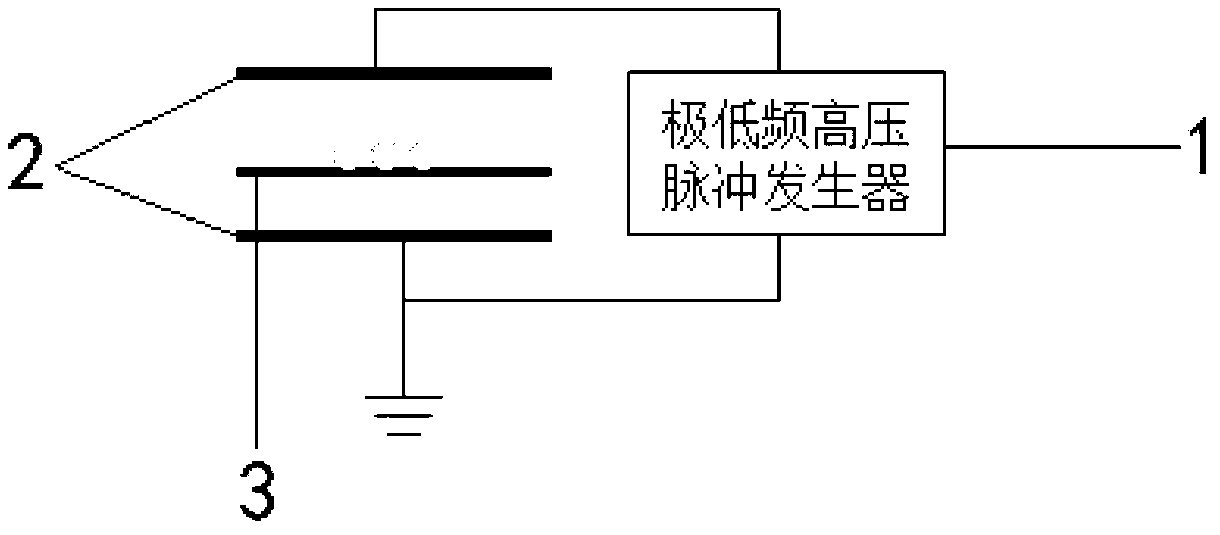

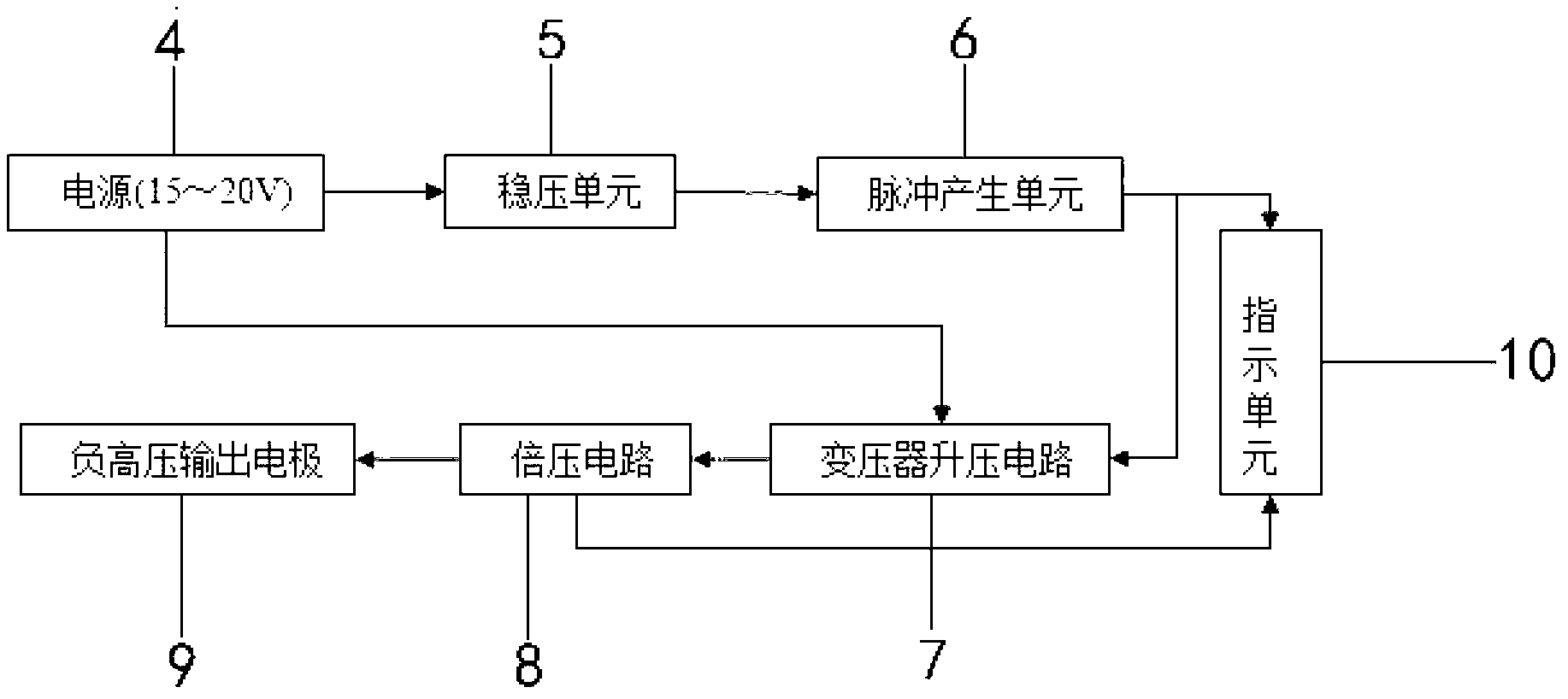

[0037] Place Lubai mung bean seeds in figure 1 The two plates shown are treated in the direction of the field strength downward, 8h per day, and 5 consecutive days of treatment, the direction of the electric field is downward, the electric field strength is 100kV / m, the pulse frequency is 1Hz, and the pulse width is 50ms. The same seeds were also taken as a control group and cultured under the same conditions, except that they were not treated with pulsed electric field, all conditions were the same.

Embodiment 2

[0039] The seeds of Zhonglv No. 2 mung bean were treated with 0.2% HgCl 2 Disinfect for 2 minutes, fully imbibition in distilled water after washing. Select uniform seeds and place them evenly in a petri dish. Place a piece of medium-speed filter paper at the bottom of the petri dish, add an appropriate amount of distilled water, and place them in a constant temperature incubator (25±0.2°C) for dark cultivation. Add distilled water regularly every day.

[0040] Place Lubai mung bean seeds in figure 1 The two plates shown are treated in the direction of the field strength downward, 8 hours per day, and 5 consecutive days of treatment. The direction of the electric field is downward, the electric field strength is 500kV / m, the pulse frequency is 0.1Hz, and the pulse width is 100ms. The same seeds were also taken as a control group and cultured under the same conditions, except that they were not treated with pulsed electric field, all conditions were the same.

Embodiment 3

[0042] The seeds of Zhonglv No. 2 mung bean were treated with 0.2% HgCl 2 Disinfect for 2 minutes, fully imbibition in distilled water after washing. Select uniform seeds and place them evenly in a petri dish. Place a piece of medium-speed filter paper at the bottom of the petri dish, add an appropriate amount of distilled water, and place them in a constant temperature incubator (25±0.2°C) for dark cultivation. Add distilled water regularly every day.

[0043] Place Lubai mung bean seeds in figure 1The two plates shown are treated in the direction of the field strength downward, each treatment is 0.5h, and after the treatment is stopped for 0.5h, the treatment is continued for 0.5h, and the treatment is repeated intermittently for 5 consecutive days. The intensity is 1000kV / m, the pulse frequency is 1Hz, and the pulse width is 1ms. The same seeds were also taken as a control group and cultured under the same conditions, except that they were not treated with pulsed electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com