Duodenum casing pipe and manufacturing method thereof

A technology of duodenum and cannula, which is applied in the field of medical engineering, can solve the problems of long-term implantation application limitations, no anti-adhesion effect, etc., and is not easy to oxidize or corrode, has good biocompatibility, and simple and easy process The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

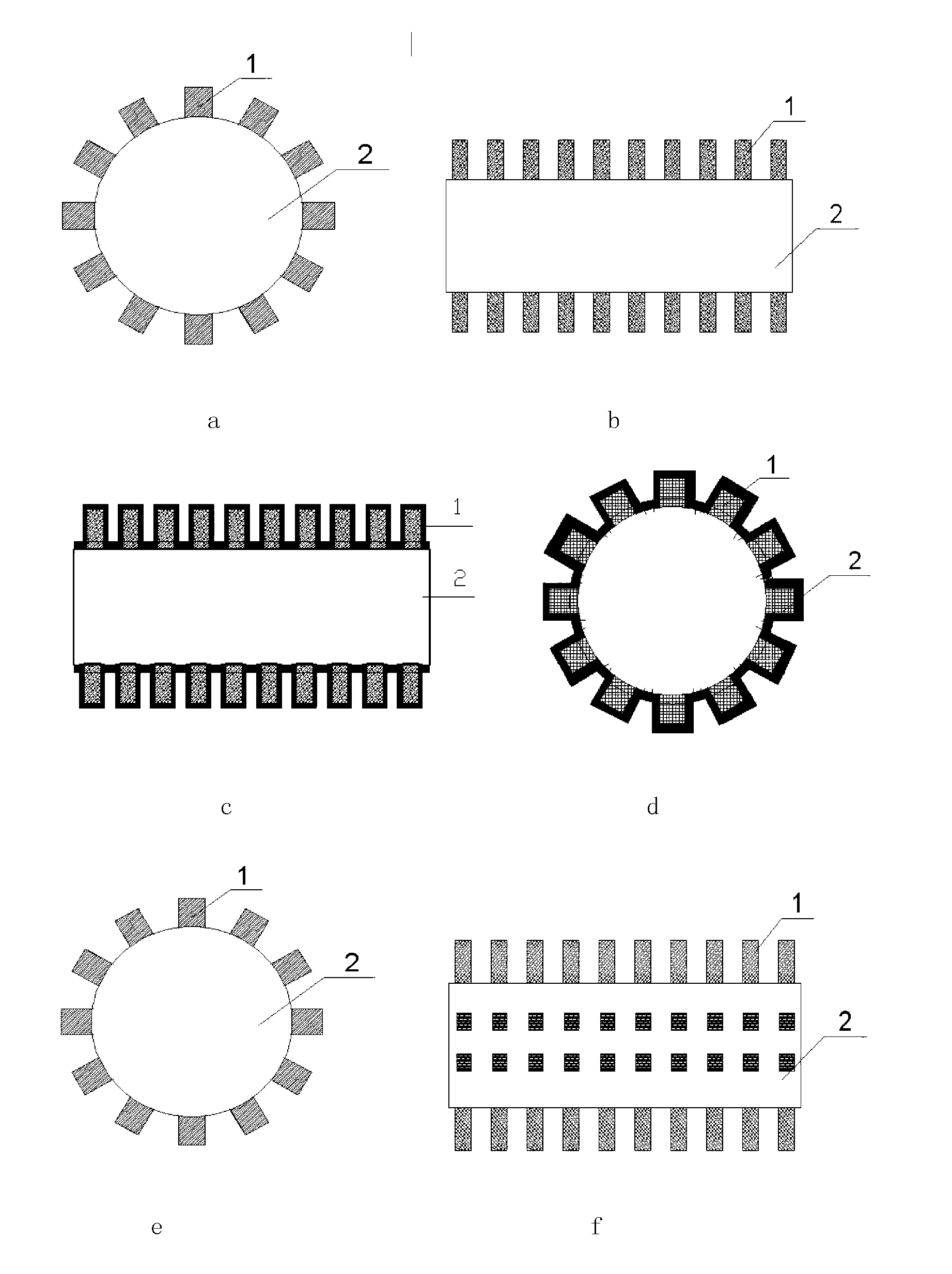

[0026] Such as figure 1 As shown, the present embodiment is processed through the following steps:

[0027] The first step is to prepare a casing with a micro-nano scale structure, and the casing is made of copper or aluminum. The micro-nano-scale structure is a micro-nano-scale cuboid structure, the bottom surface of the cuboid is a square, and its size is: the length and width are 1 micron to 10 microns, the height of the cuboid is 5 microns to 50 microns, and the distance between each cuboid is It is 1 micron-10 micron. Such as figure 1 As shown in a and b, 1 is the main body of the mold, and 2 is the micro-nano scale structure. in figure 1 Among them, a is the top view of the mold, and b is the side view of the mold.

[0028] In the second step, a polymer film sleeve is chemically vapor deposited on the surface of the mold.

[0029] A polymer film is deposited on the surface of the mold with micro-nano scale structure by chemical vapor deposition. 1 is a polymer fil...

Embodiment 2

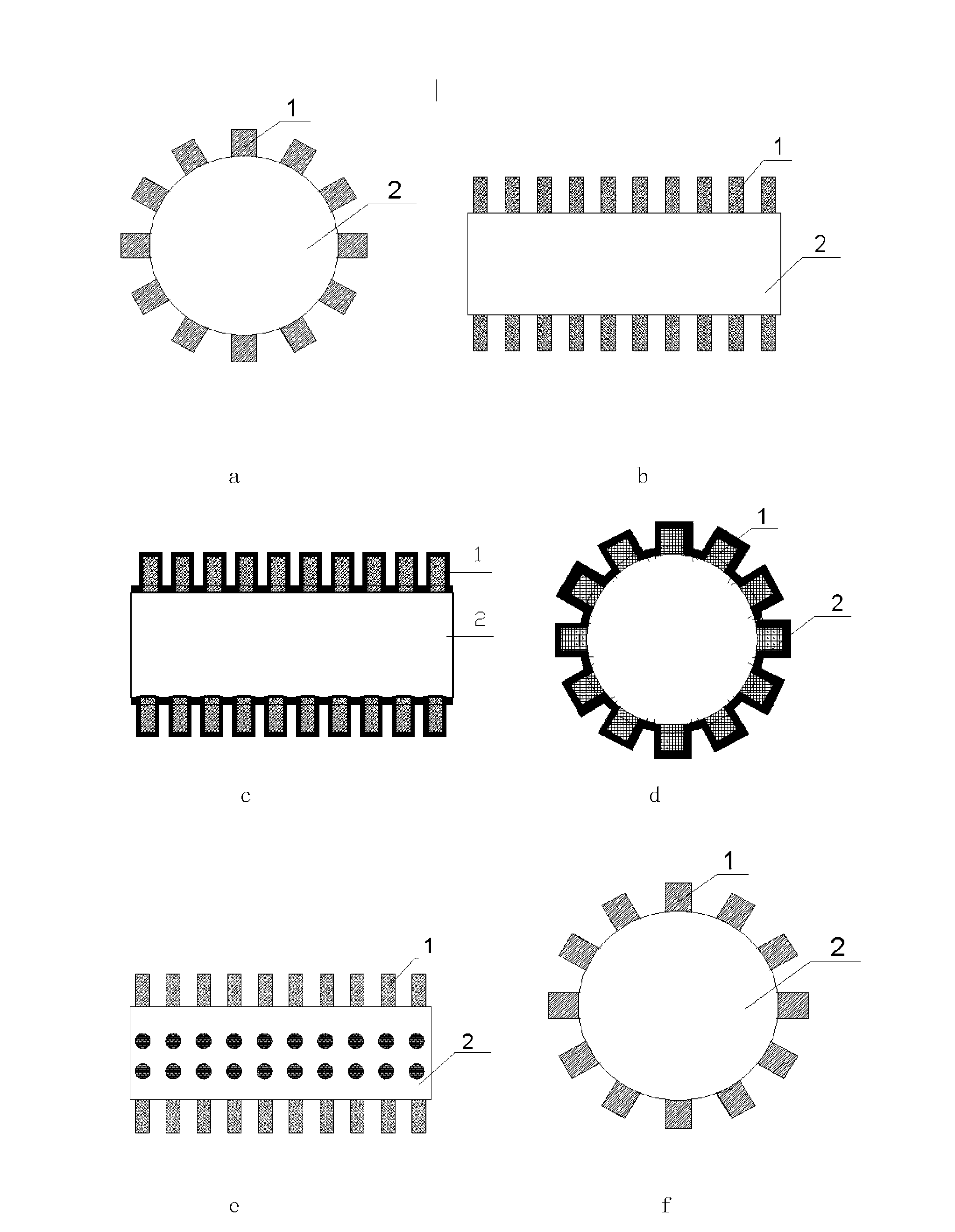

[0035] Such as figure 2 Shown, the present embodiment is prepared through the following steps:

[0036] The first step is to prepare a casing with a micro-nano scale structure, and the casing is made of copper or aluminum. The micro-nano scale structure is a micro-nano scale cylinder structure. The radius of the bottom circle is 0.5 micron-5 micron, the height of the cylinder is 5 micron-50 micron, and the interval between each cylinder is 1 micron-10 micron, such as figure 2 As shown in a and b, 1 is the main body of the mold, and 2 is the micro-nano scale structure. in figure 2 A is the top view of the mold, figure 2 Middle b is the side view of the mould.

[0037] In the second step, a polymer film sleeve is chemically vapor deposited on the surface of the mold.

[0038] A polymer film is deposited on the surface of the mold with micro-nano scale structure by chemical vapor deposition. 1 is a polymer film. 2 is a casing mold. figure 2 Among them, c is a side v...

Embodiment 3

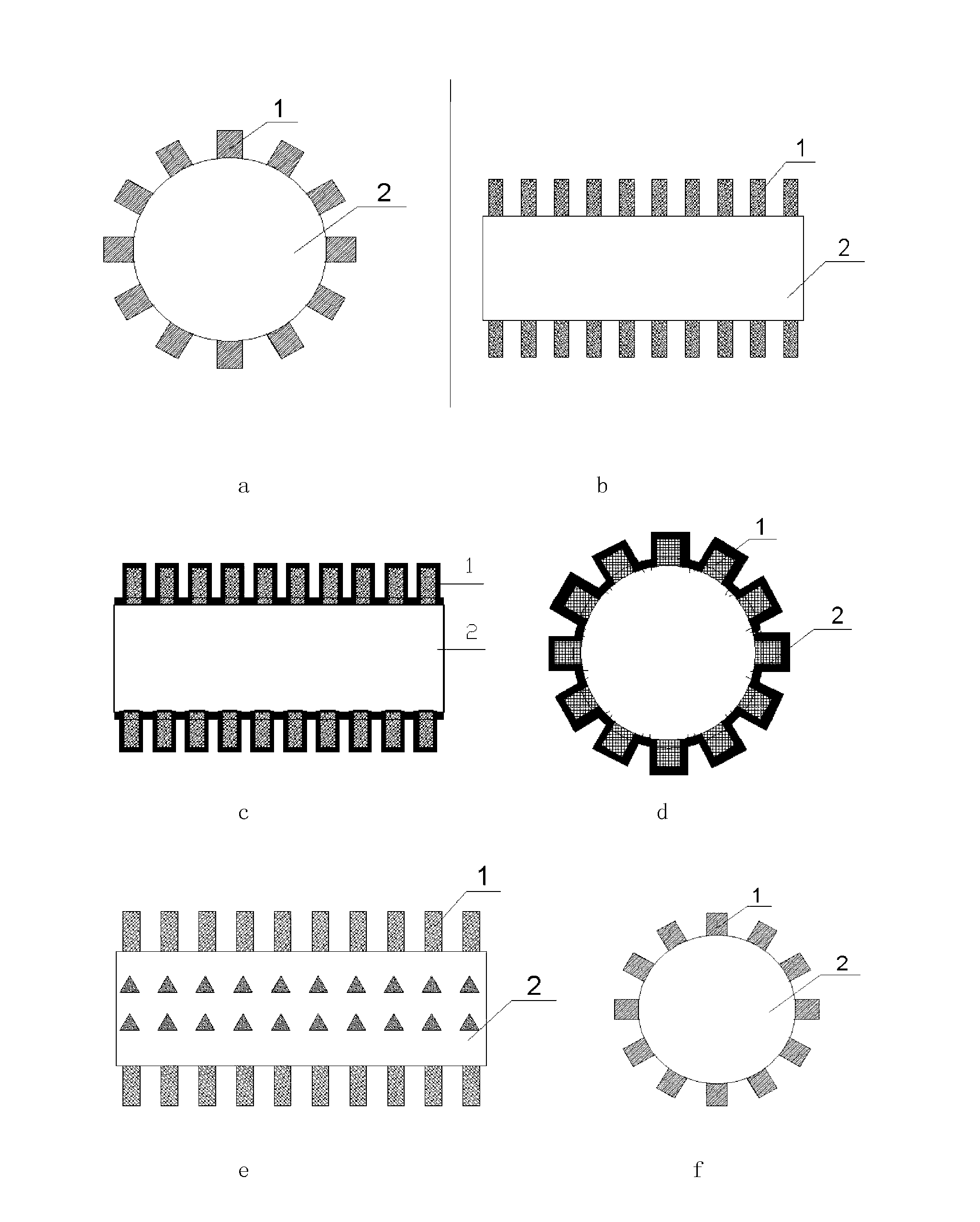

[0042] Such as image 3 Shown, the present embodiment is prepared through the following steps:

[0043] The first step is to prepare a casing with a micro-nano scale structure, and the casing is made of copper or aluminum. The micro-nano scale structure is a micro-nano scale triangular prism structure. The base of the triangular prism is an equilateral triangle, the side length is 1 micron-10 micron, the height of the triangular prism is 5 micron-50 micron, and the interval between each triangular prism is 1 micron-10 micron. Such as image 3 As shown in a and b, 1 is the main body of the mold, and 2 is the micro-nano scale structure. in image 3 Among them, a is the top view of the mold, and b is the side view of the mold.

[0044] In the second step, a polymer film sleeve is chemically vapor deposited on the surface of the mold.

[0045] A polymer film is deposited on the surface of the mold with micro-nano scale structure by chemical vapor deposition. . 1 is a polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com