Thermal radiation type welding method and device applied to solar cell

A technology of solar cells and welding devices, which is applied in the direction of electric heating devices, auxiliary devices, welding equipment, etc., can solve the problems of many required personnel, difficulty in production organization and quality control, production cost control, and many processes, so as to achieve welding Time and welding temperature, good controllability of welding time and temperature, and good welding quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

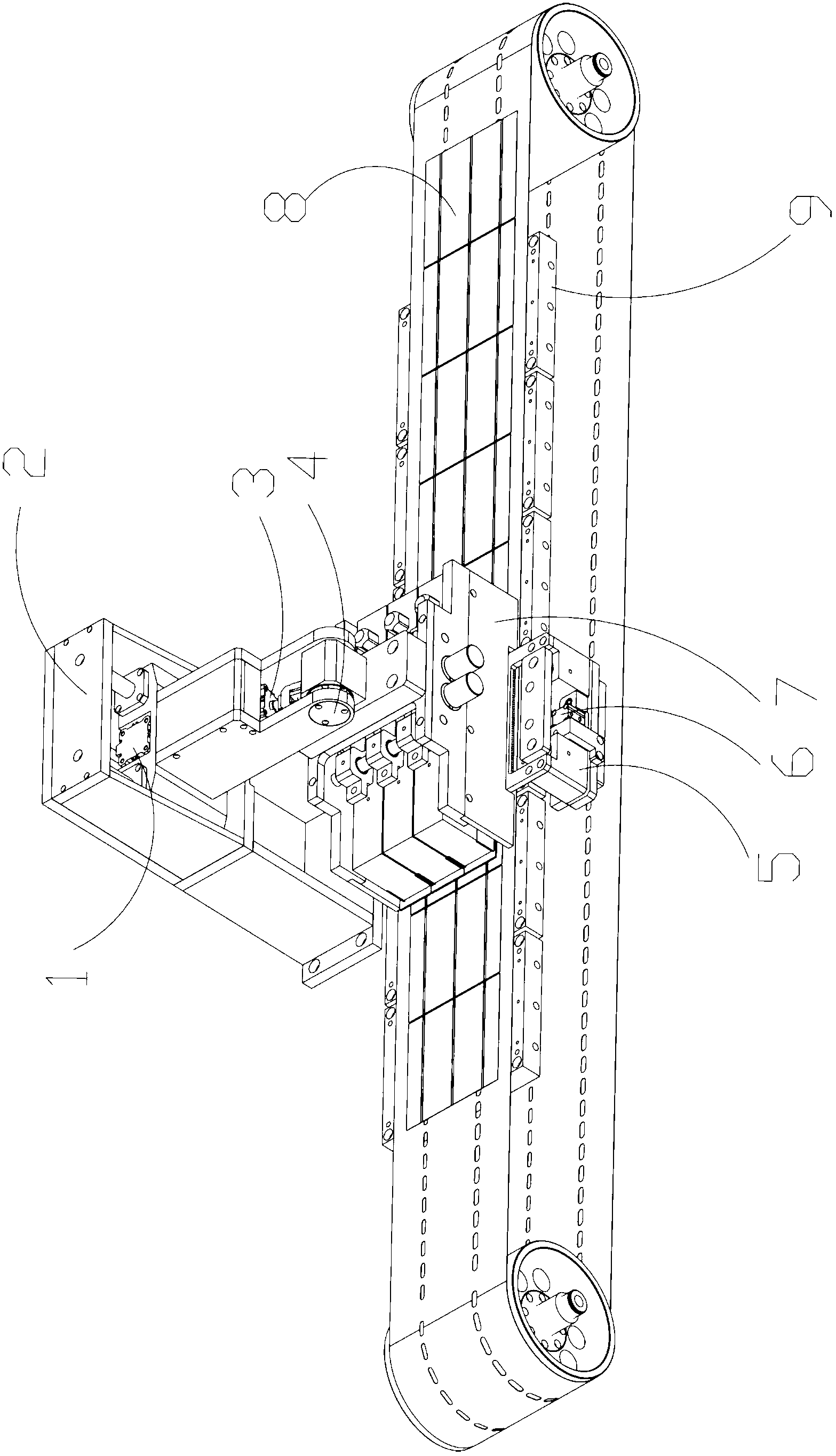

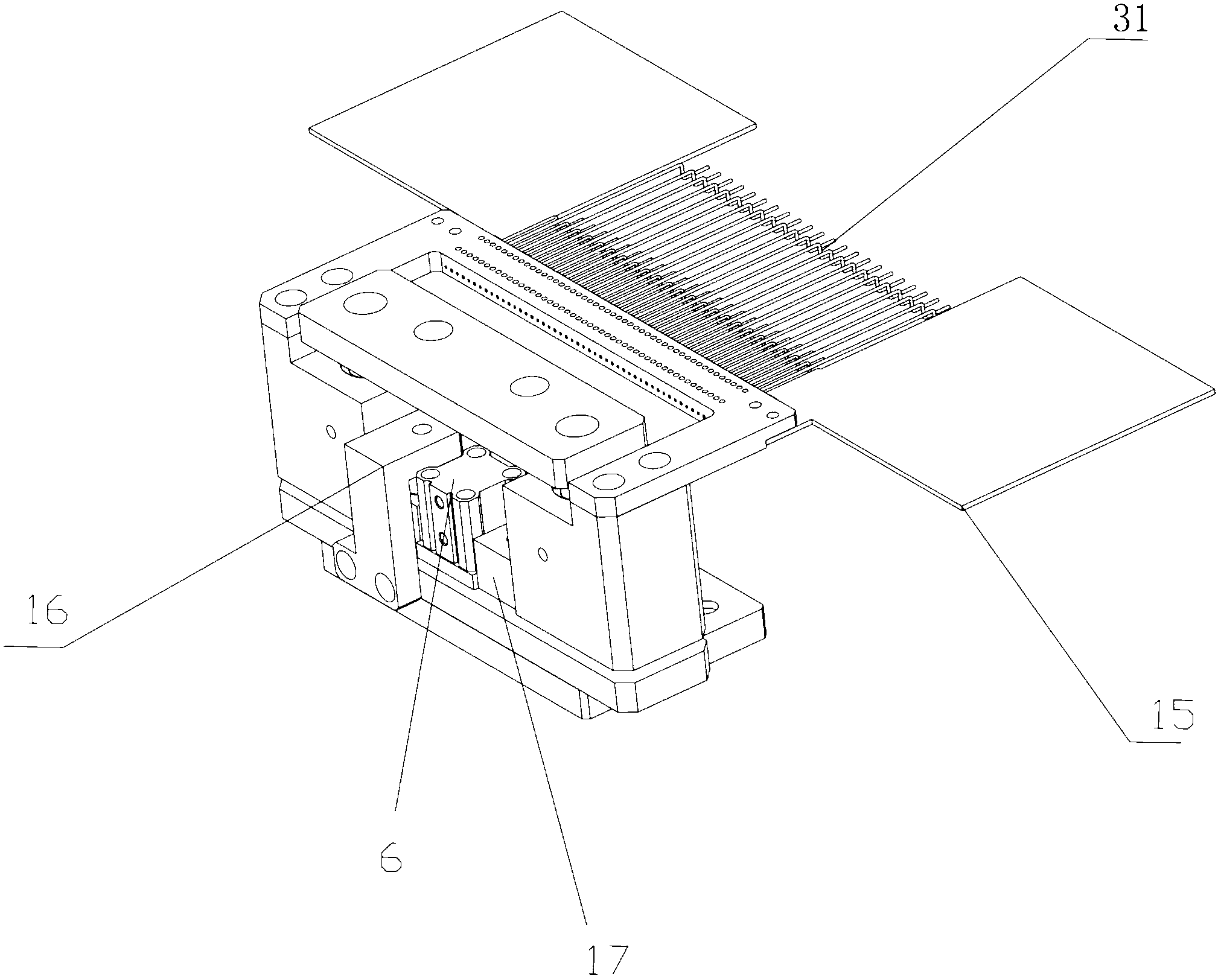

[0021] Such as figure 1 As shown, a thermal radiation welding device applied to solar cells includes an infrared heating device 7, a needle pressing device 5 and a preheating device 9, and the pressing needle device 5 is placed under the infrared heating device 7, and the infrared heating device 7. The needle pressing device 5 is placed in the middle of the preheating device 9 .

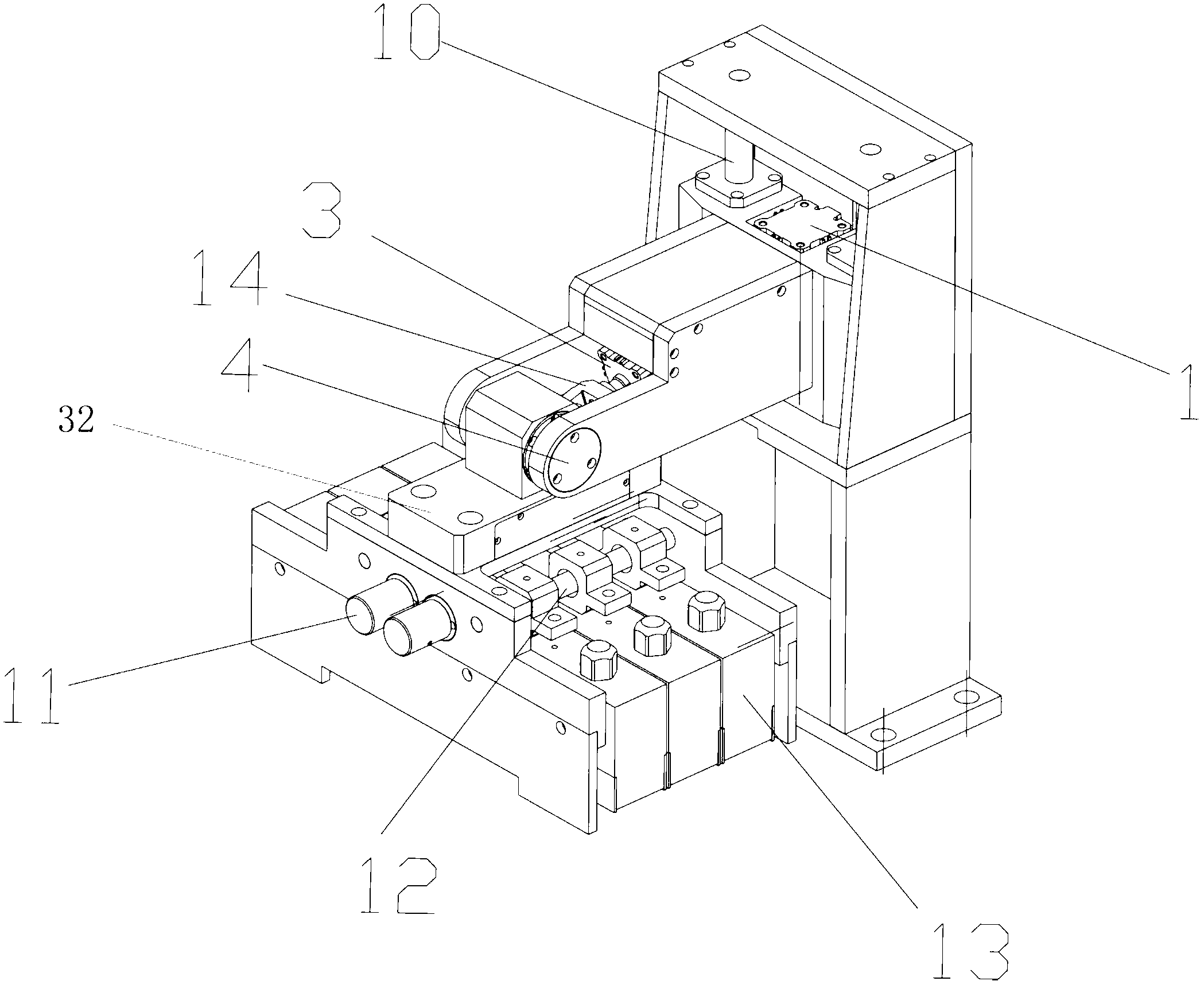

[0022] Such as figure 1 , figure 2 and Figure 4 As shown, the infrared pneumatic turning device 2 and the infrared heating device 7, the outer line pneumatic turning device includes a lifting cylinder 1, a turning cylinder 3, a rotating shaft 33 and a bearing seat 32, and the infrared heating device 7 is connected to the bearing seat 32, so The bearing seat 32 has a built-in bearing, and the inner hole of the bearing is installed with a rotating shaft 33, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com