3'-thionucleoside synthesis method

A compound and mixture technology, which is applied in the production of bulk chemicals, sugar derivatives, organic chemistry, etc., can solve the problems of low purity, low yield of target products, lengthy synthetic routes, etc., and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

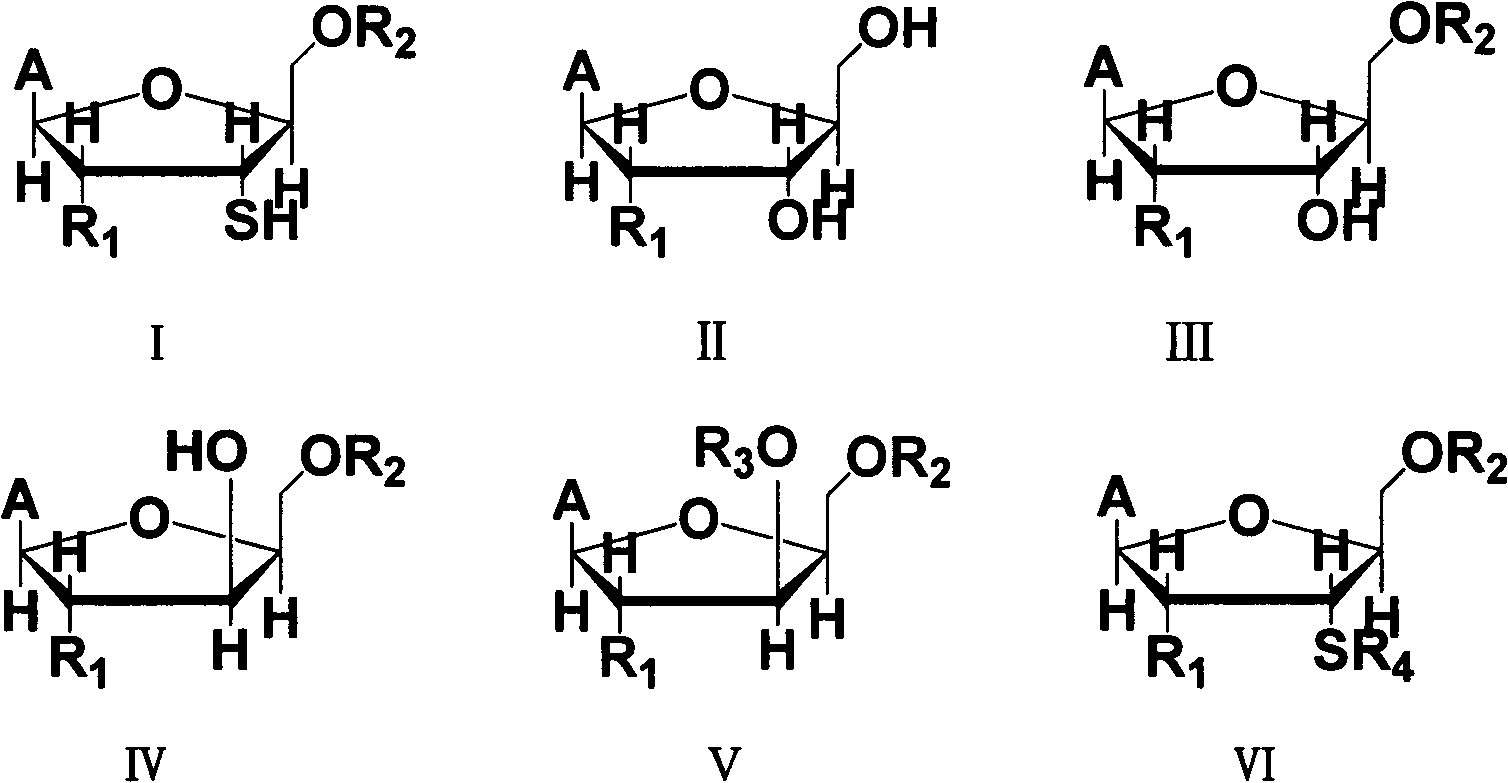

Method used

Image

Examples

Embodiment 1

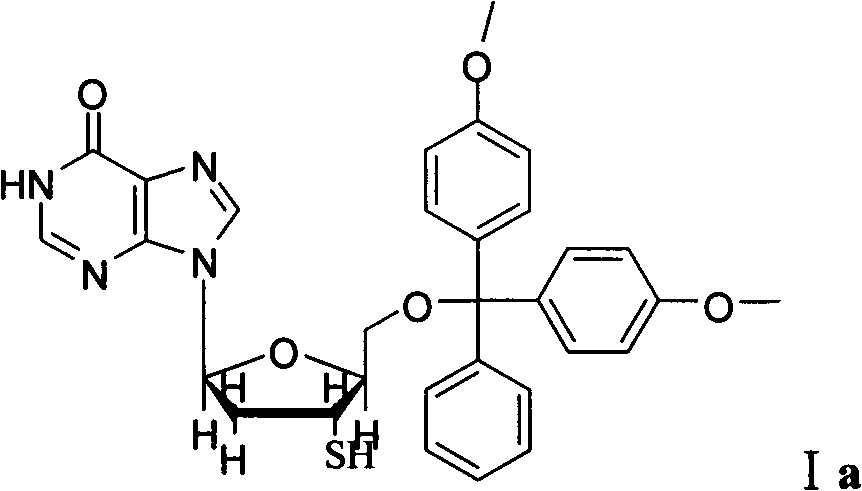

[0037] The preparation of compound shown in formula Ia:

[0038]

[0039] Dissolve 2'-deoxyinosine (0.2520g, 1.0mmol) in 10mL of treated anhydrous DBU, start stirring, and slowly add DMTCl (0.4060g, 1.2mmol) to the two-necked flask, and the reaction solution continues to be heated at room temperature. The reaction was stirred for 19h. Pass through a silica gel column, first remove pyridine with an eluent (DCM:EtOH=20:1, V / V), and then increase the polarity to obtain the product. The product is a white solid 0.5483g (5'-DMT-2'- Deoxyinosine, compound IIIa), the yield was 98.97%.

[0040] Dissolve Sareite reagent (0.6400g, 1.5mmol) in 8mL of treated anhydrous dichloromethane, start stirring, then cool in ice bath for 10min, slowly add compound 5′-DMT-2′-deoxyinosine (0.5440 g, 1.0mmol), then react in ice bath for 1h, remove the ice bath, slowly rise to room temperature and continue the reaction for 4h, add 8mL of anhydrous isopropanol dropwise to the reaction solution, add ...

Embodiment 2

[0048] The preparation of compound shown in formula I b:

[0049]

[0050] Except that 2-acetamide-2'-deoxyadenosine was substituted for 2'-deoxyinosine in Example 1, other conditions were the same as in Example 1 to obtain the title compound. The purity of the title compound was 98%, and its overall yield was about 45%.

[0051] 1 H NMR (400MHz, CDCl 3 ): δ10.32(s, 1H), 8.30(s, 1H), 6.97(s, 2H), 7.43-6.84(m, 13H), 5.94(dd, 1H, J 1 = 4.0Hz,J 2 =8Hz), 4.38(m, 1H), 3.83(s, 6H), 3.63(dd, 1H, J 1 = 4.0Hz,J 2 =8Hz), 3.38(dd,1H,J 1 = 4.0Hz,J 2 =8Hz), 2.90(m, 1H), 2.68(m, 1H), 2.43(m, 1H), 2.04(s, 3H), 1.58(d, 1H, J=8Hz).

[0052] MS(ESI): m / z calcd for C 33 h 34 N 6 o 5 S: [M+H + ]: 627.2; found: 627.3.

Embodiment 3

[0054] The preparation of compound shown in formula Ic:

[0055]

[0056] According to the method described in Example 1, only changing the raw material 2′-deoxyinosine to 2-acetamide-6-benzamide-2′-deoxyadenosine, and DMTCl to TBSCl can successfully obtain the title compound. The purity of the title compound was 98%, and its overall yield was about 49%.

[0057] 1 H NMR (400MHz, CDCl 3 ): δ11.34(s, 1H), 10.32(s, 1H), 8.36(s, 1H), 8.05-6.84(m, 5H), 5.94(dd, 1H, J 1 = 4.0Hz,J 2 =8Hz), 4.38(m, 1H), 4.20(m, 1H), 3.73(s, 1H), 2.93(dd, 1H, J 1 = 4.0Hz,J 2 =8Hz), 2.68(dd,1H,J 1 = 4.0Hz,J 2 =8Hz), 2.40(m, 1H), 2.08(s, 3H), 1.60(d, 1H, J=8Hz), 0.21(s, 9H).

[0058] MS(ESI): m / z calcd for C 22 h 28 N 6 o 4 SSi: [M+H + ]: 501.2; found: 502.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com