Preparation method of low-density thermoplastic polyimide micro-foamed material

A technology of polyimide and thermoplastic, applied in the field of preparation of polyimide micro-foaming materials, can solve the problems of high density, high content of open-cell structure, large cell size of foaming materials, etc., and achieve cell structure Uniformity, simple and easy preparation method, high cell density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

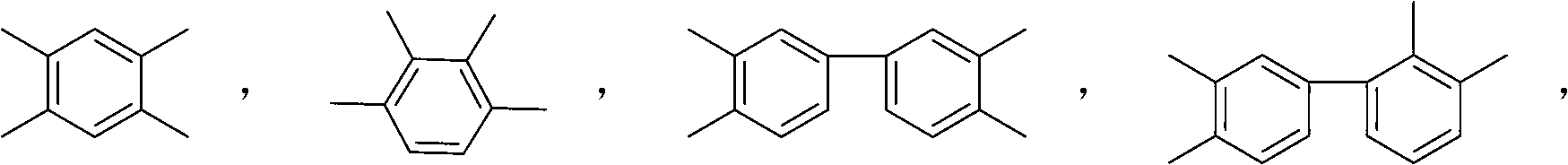

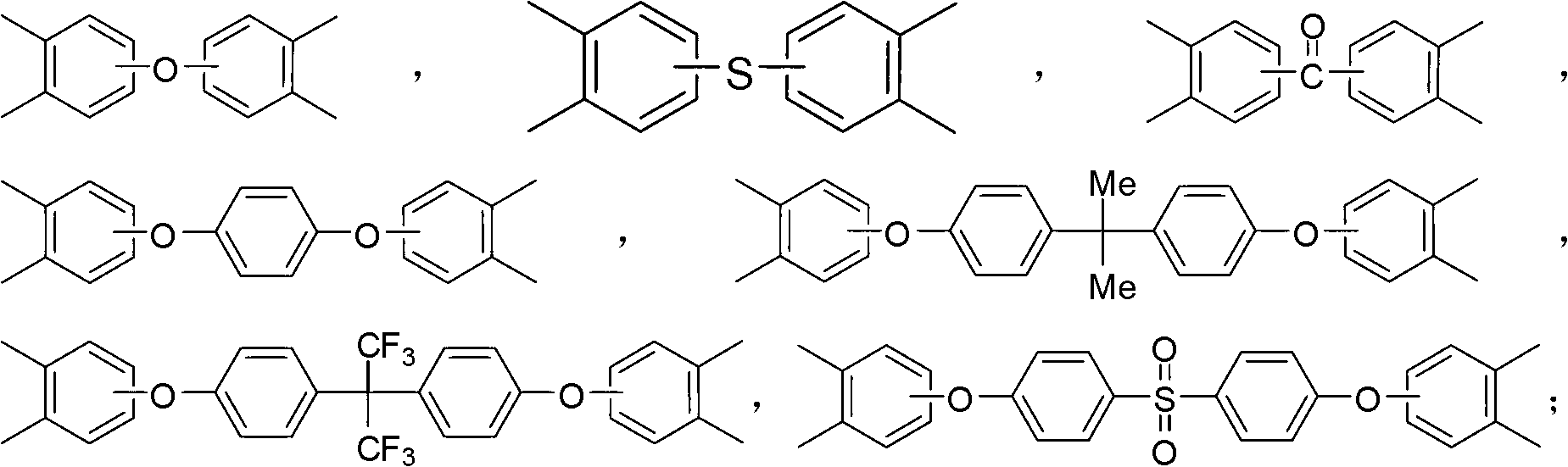

[0040] In the present embodiment, thermoplastic polyimide selects the Ultem1010 polyimide of GE Company for use, and its molecular structural formula is where A is B for

[0041] high pressure CO 2 The above-mentioned thermoplastic polyimide is physically foamed with high-pressure tetrahydrofuran fluid, and the specific foaming process is as follows:

[0042] (1) Inject thermoplastic polyimide into a single screw under high pressure, and melt extrude to prepare a polyimide sheet with a thickness of 2mm;

[0043] (2) Put the thermoplastic polyimide sheet prepared in step (1) into the autoclave, and pass CO at a pressure of 5MPa 2 and tetrahydrofuran high-pressure fluids to make CO 2 Saturated with tetrahydrofuran in the polyimide sheet, the saturation temperature is 10°C, and the saturated polyimide sheet is obtained;

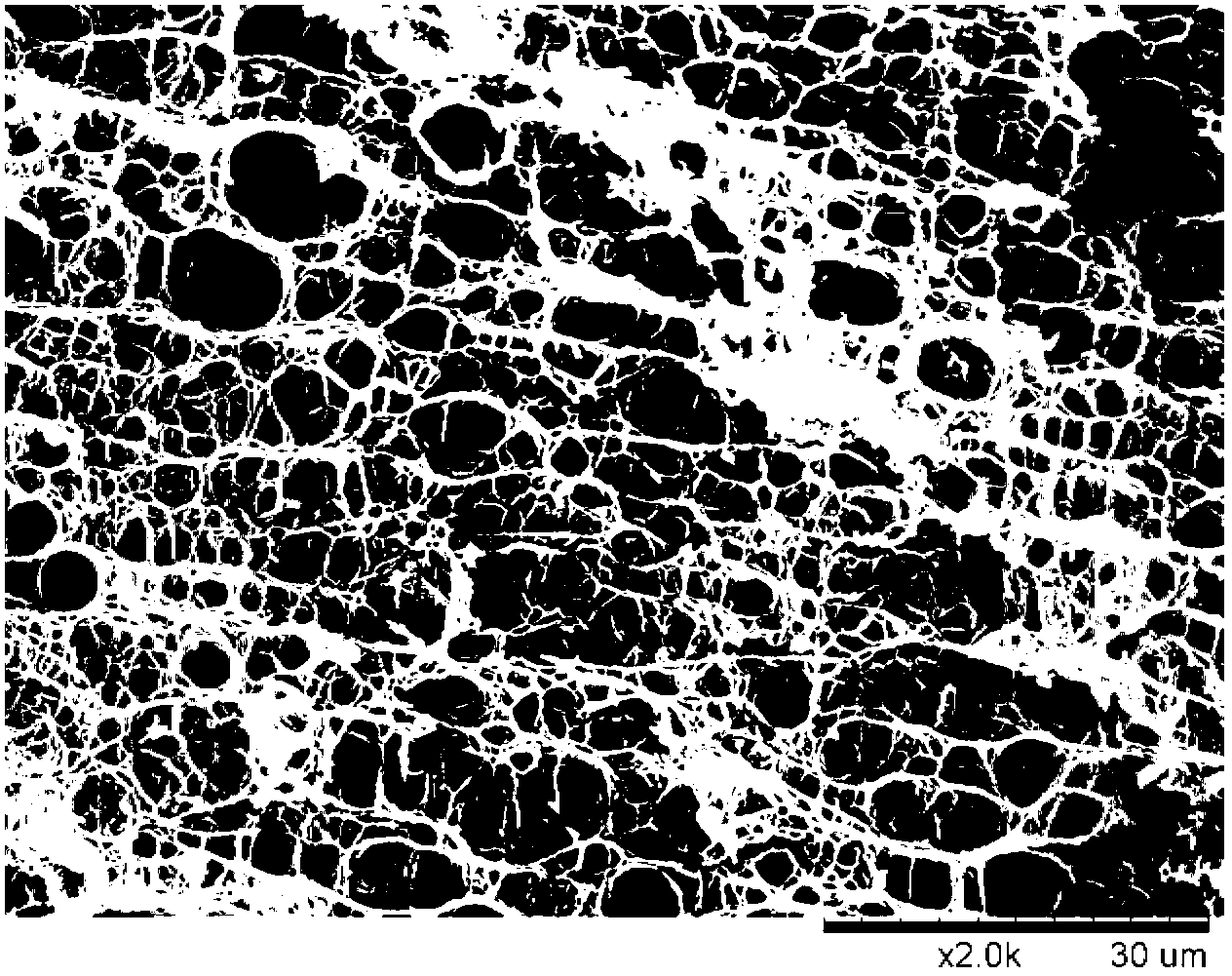

[0044] (3) Put the saturated polyimide sheet into a mold, and then foam it in a high-temperature oil bath at 220° C. for 30 seconds to obtain a microfo...

Embodiment 2

[0065] In this embodiment, the thermoplastic polyimide is the same as that selected in Embodiment 1. In this embodiment 1, high-pressure HFC-245fa and high-pressure tetrahydrofuran fluid are used to physically foam the above-mentioned thermoplastic polyimide, and the specific foaming process is as follows:

[0066] (1) Inject thermoplastic polyimide into a single screw under high pressure, and melt extrude to prepare a polyimide sheet with a thickness of 2mm;

[0067] (2) Put the thermoplastic polyimide sheet prepared in step (1) into an autoclave, and feed HFC-245fa and tetrahydrofuran high-pressure fluid with a pressure of 12MPa to make HFC-245fa and tetrahydrofuran in the polyimide sheet The material reaches saturation, and the saturation temperature is 100°C to obtain a saturated polyimide sheet;

[0068] (3) Put the saturated polyimide sheet into a mold, and then foam it in a high-temperature oil bath at 170° C. for 20 seconds to obtain a microfoamed polyimide sheet.

...

Embodiment 3

[0081] In this embodiment, the thermoplastic polyimide is the same as that selected in Embodiment 1. In this example, high pressure CO 2 The above-mentioned thermoplastic polyimide is physically foamed with methanol fluid, and the specific foaming process is as follows:

[0082] (1) Inject thermoplastic polyimide into a single screw under high pressure, and melt extrude to prepare a polyimide sheet with a thickness of 5mm;

[0083] (2) Put the thermoplastic polyimide sheet prepared in step (1) into an autoclave, and pass CO at a pressure of 15MPa 2 and methanol high-pressure fluids that make CO 2 Saturation with methanol in the polyimide sheet, the saturation temperature is 100°C, to obtain a saturated polyimide sheet;

[0084] (3) Put the saturated polyimide sheet into a mold, and then foam it in a high-temperature oil bath at 240° C. for 15 seconds to obtain a microfoamed polyimide sheet.

[0085] The polyimide micro-foamed sheet prepared above has smooth surface, soft t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com